Multi-degree-of-freedom laser quenching device allowing position adjustment of workpieces

A technology of workpiece position and laser quenching, applied in the direction of quenching device, manufacturing tool, furnace type, etc., can solve the problems of difficult to achieve movement trajectory, high cost, unfavorable processing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

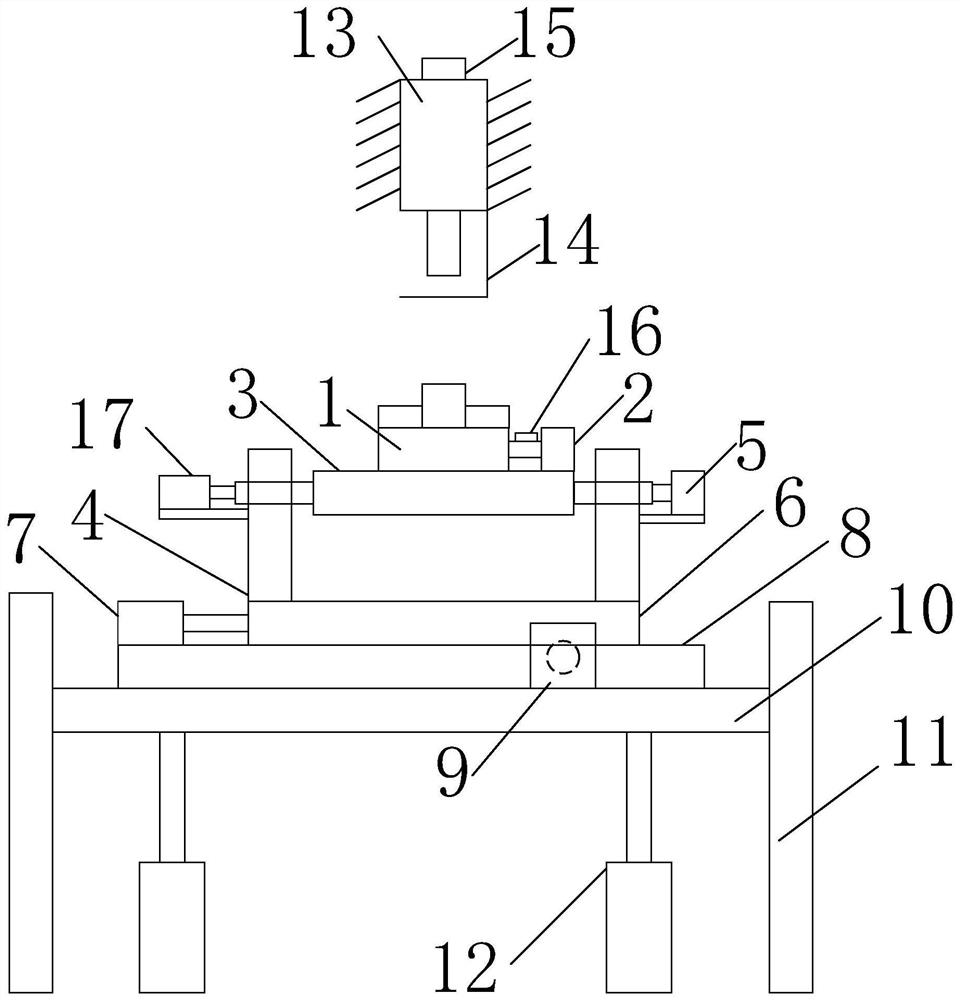

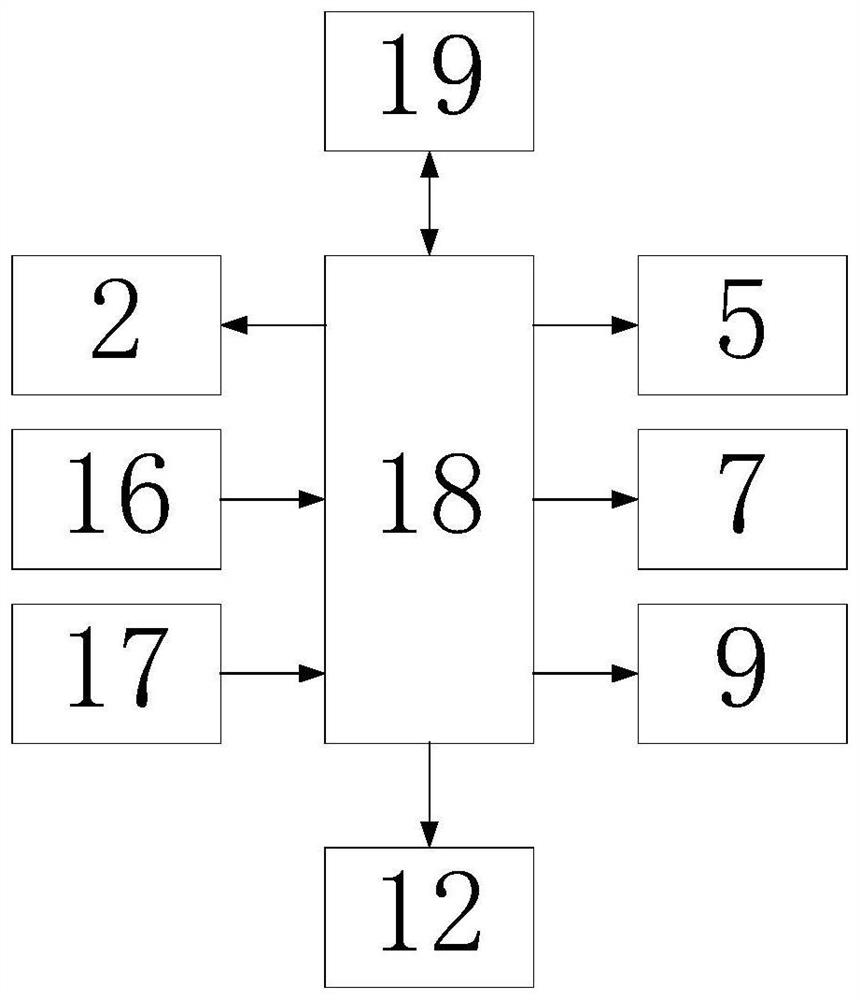

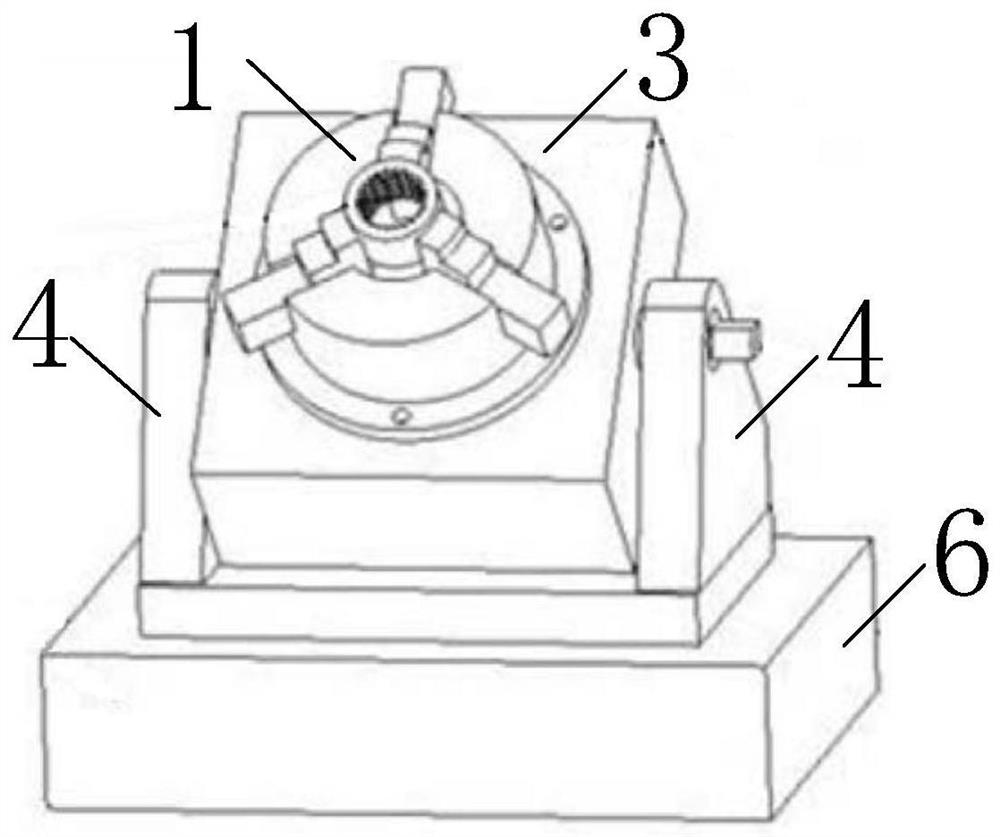

[0027] A laser quenching device with adjustable position of multi-degree-of-freedom workpiece, comprising: clamping head 1, clamping head 1 is driven by clamping head motor 2 to clamp or loosen, clamping head 1 is fixed on rotating plate 3, rotates The two ends of the plate 3 are respectively rotatably connected to the rotating support 4, and the rotatable connecting shaft axis at one end of the rotating plate 3 is connected to the rotating motor 5, the cylinder body of the rotating motor 5 is fixed on the rotating support 4, and the rotating support 4 is fixed on the horizontal supporting plate 6 , the transverse support plate 6 moves horizontally on the longitudinal support plate 8 driven by the transverse drive device 7, the transverse drive device 7 is arranged on the transverse support plate 6, and the longitudinal support plate 8 moves ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com