PVDC co-extrusion base material film as well as preparation method and application thereof

A base film and extruder technology, which is applied in the field of PVDC co-extrusion base film and its preparation, can solve the problems of difficult processing and forming, difficult layering, and flatness, so as to improve production efficiency and yield, improve Film quality, effect of reducing shear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

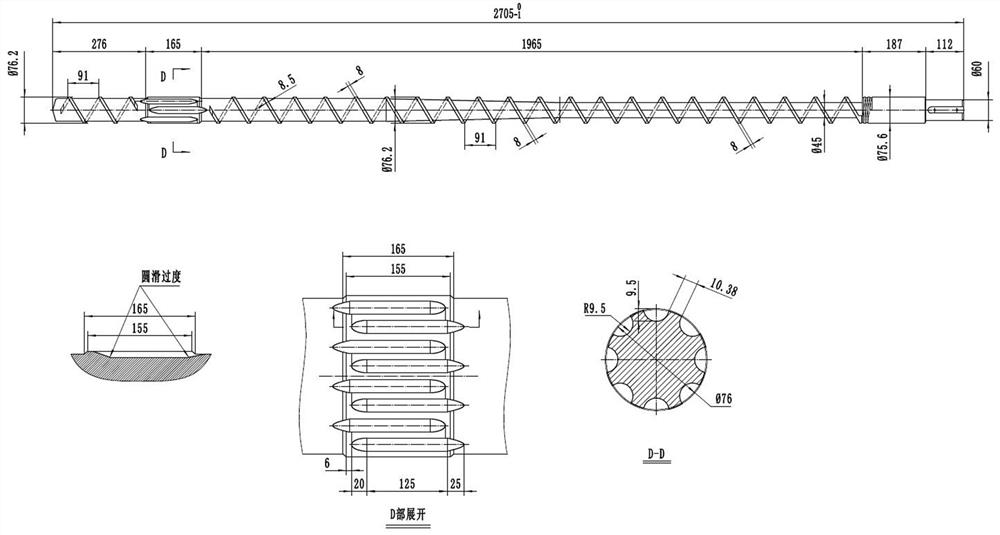

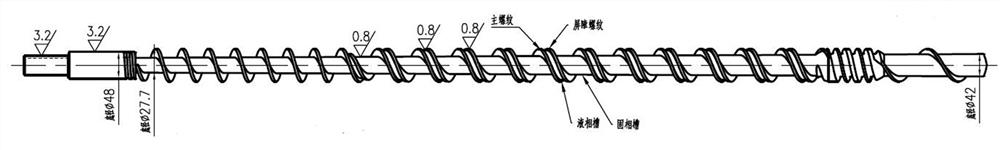

Method used

Image

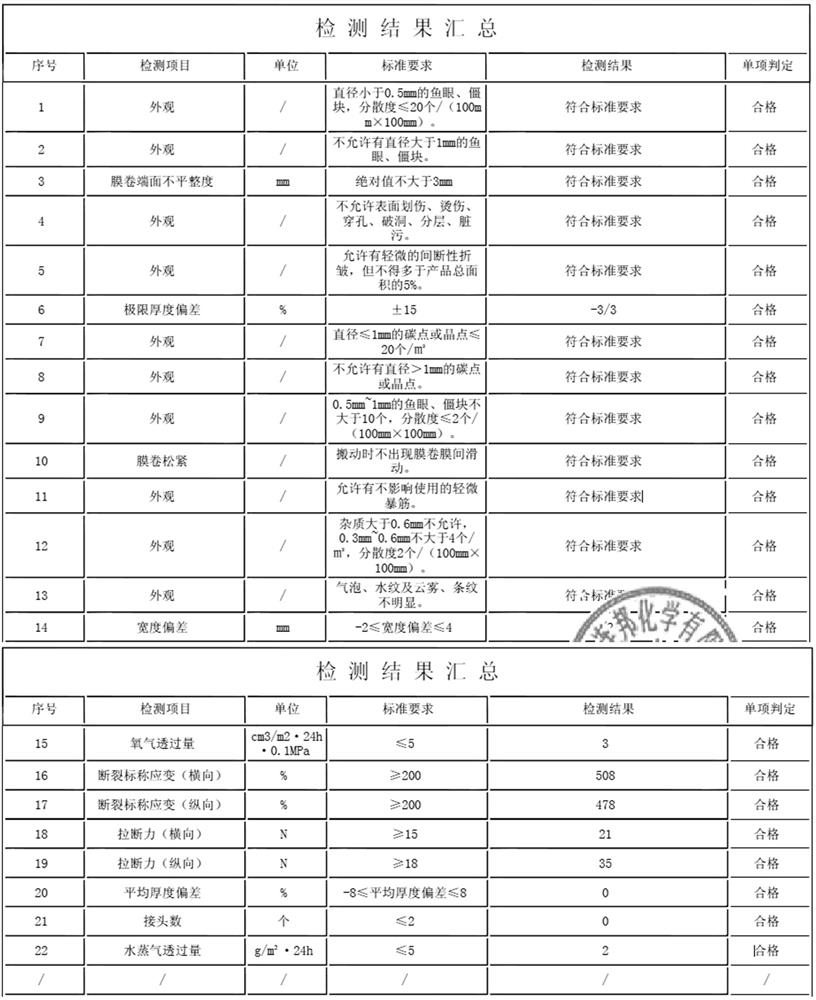

Examples

Embodiment 1

[0027] The preparation method of the skin color PVDC co-extrusion substrate film of the present embodiment, the steps are as follows:

[0028] (1) PVDC resin enters the screw groove and screw barrel through the feeding port, and melts at a high temperature of 160°C to form a molten resin; EVA resin enters the screw groove and screw barrel through the feeding port, and is melted at a high temperature of 170°C to form a molten resin. molten resin;

[0029] (2) This product adopts EVA and PVDC resin according to the ratio of 3:1, through the screws of different diameters and separately stacked die heads, after the adjustment of the temperature in different areas, the central cylinder is laminated layer by layer, and moves from bottom to top, and finally forms The multi-layer structure is extruded by the die lip, and the slip agent SAB808 is added to the inner layer at the same time, and then blown and cooled by air cooling at 8°C, and then formed into a film through a nip roller,...

Embodiment 2

[0033] The preparation method of the transparent PVDC co-extrusion substrate film of the present embodiment, the steps are as follows:

[0034] (1) PVDC resin enters the screw groove and screw barrel through the feeding port, and melts at a high temperature of 160°C to form a molten resin; EVA resin enters the screw groove and screw barrel through the feeding port, and is melted at a high temperature of 170°C to form a molten resin. molten resin;

[0035] (2) This product uses EVA and PVDC resins to pass through screws of different diameters and separate superimposed dies. After adjusting the temperature in different areas, it is bonded layer by layer through the central cylinder, and moves from bottom to top, and finally forms a multi-layer structure. The lip is extruded, and at the same time, a slip agent is added to the inner layer, and then it is blown and cooled by air cooling at 8°C, and it is formed into a film through a nip roller, a knife and a winding device.

[003...

Embodiment 3

[0039] The preparation method of the PVDC co-extrusion substrate film of the present embodiment, the steps are as follows:

[0040] (1) PVDC resin enters the screw groove and screw barrel through the feeding port, and melts at a high temperature of 160°C to form a molten resin; EVA resin enters the screw groove and screw barrel through the feeding port, and is melted at a high temperature of 170°C to form a molten resin. molten resin;

[0041](2) This product uses EVA and PVDC resins to go through screws of different diameters and separate superimposed die heads, after adjusting the temperature in different areas, and then laminating layer by layer through the central cylinder, moving from bottom to top, and finally forming a multi-layer structure. The lip is extruded, and at the same time, a slip agent is added to the inner layer, and then it is blown and cooled by air cooling at 8°C, and it is formed into a film through a nip roller, a knife and a winding device.

[0042] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com