Biomass fuel and preparation method of biomass fuel

A biomass fuel and waste technology, applied in the direction of biofuel, waste fuel, fuel, etc., to achieve high calorific value, reduce environmental pollution, and save the cost of solid waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

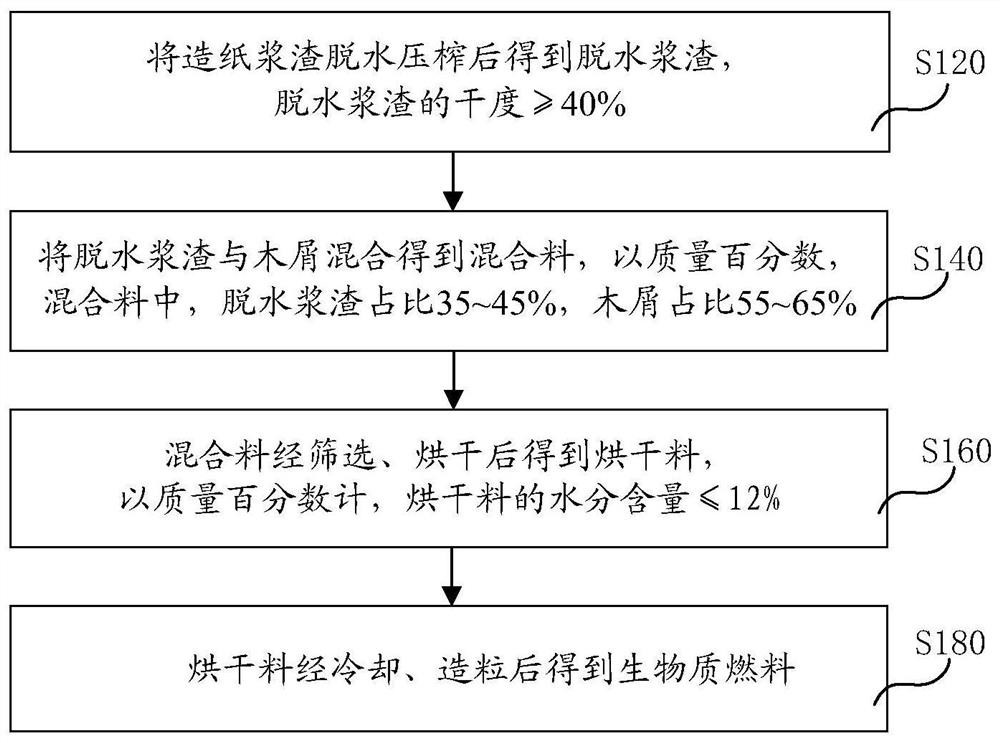

[0032] The present embodiment provides a kind of preparation method of biomass fuel, and this preparation method comprises the following steps:

[0033] S120: dehydrating and pressing the papermaking pulp residues to obtain dehydrated pulp residues, the dryness of the dehydrated pulp residues being greater than or equal to 40%.

[0034] Papermaking pulp is the solid waste produced in the process of pulp and papermaking in paper mills. Depending on the pulping process, the papermaking rejects in this application can be mechanical pulp rejects, chemical-mechanical pulp rejects, or chemical pulp rejects.

[0035] The dryness of the dehydrated pulp slag is more than 40%, which can reduce the moisture content in the raw material, which is beneficial to the subsequent processing of the raw material, and can effectively control the moisture content in the biomass fuel and improve the performance of the biomass fuel.

[0036]The dryness of dewatered pulp can be: 40%, 45%, 48% or 50%....

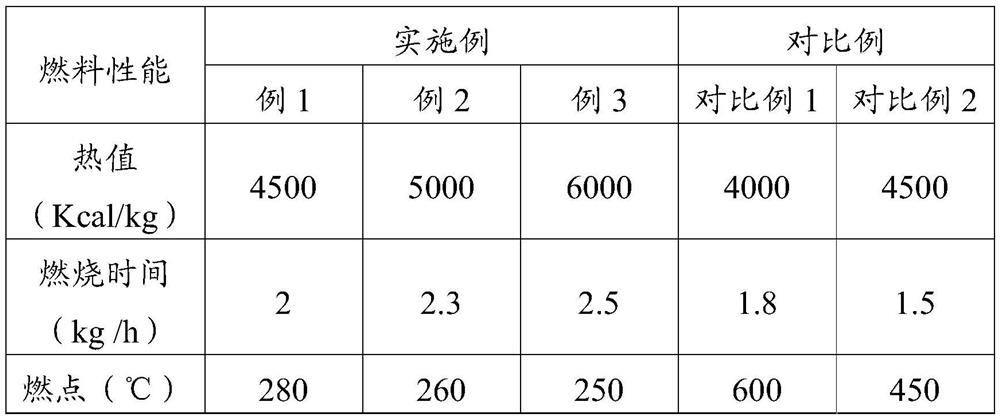

example 1

[0090] In terms of mass percentage, the raw materials for the production of biomass fuel include: 35% dehydrated pulp and 65% wood chips. The dehydrated pulp is obtained by dehydrating and pressing the chemical-mechanical pulp, and the dryness of the dehydrated pulp is 40%. Biomass fuel is obtained after screening, drying, cooling and granulation. The moisture content of the biomass fuel was 12%.

example 2

[0092] In terms of mass percentage, the raw materials for the production of biomass fuel include: 40% dehydrated pulp and 60% wood chips. The dehydrated pulp is obtained by dehydrating and pressing the chemical-mechanical pulp, and the dryness of the dehydrated pulp is 45%. Biomass fuel is obtained after screening, drying, cooling and granulation. The moisture content of the biomass fuel was 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com