A kind of bola type organosilicon quaternary ammonium salt and its preparation method and application

An organosilicon quaternary ammonium salt, chain reaction technology, applied in fiber treatment, textile and papermaking, biochemical fiber treatment, etc. Yellow and other problems, to achieve the effect of obvious whiteness and improve the whiteness of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

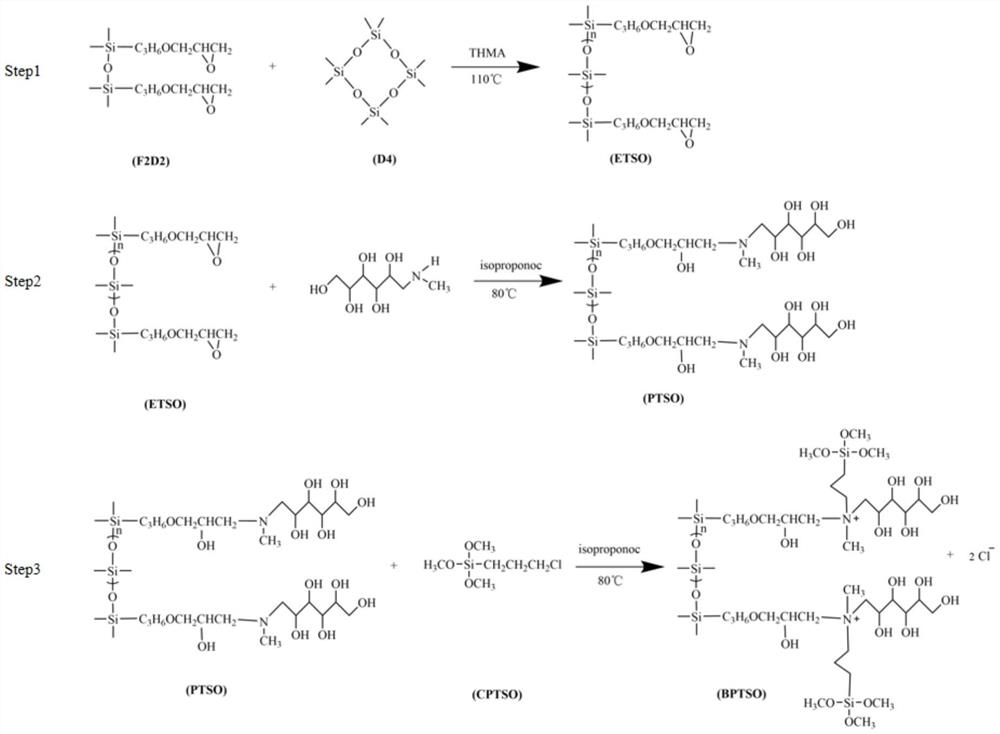

[0033] The invention provides a kind of preparation method of Bola type organic silicon quaternary ammonium salt, comprises the following steps:

[0034] A) Under protective atmosphere conditions, the addition reaction of allyl glycidyl ether and tetramethyldisiloxane is carried out to obtain the epoxy double head F 2 D. 2 ;

[0035] B) the epoxy double head F 2 D. 2 Mix and heat with octamethylcyclotetrasiloxane to carry out chain extension reaction to obtain epoxy-terminated silicone oil ETSO;

[0036] C) mixing and heating the epoxy-terminated silicone oil ETSO and meglumine, and performing an amination reaction to obtain the silicone block silicone oil PTSO;

[0037] D) Mixing and heating the organosilicon block silicone oil PTSO and a quaternizing agent to perform a quaternization reaction to obtain a Bola-type organosilicon quaternary ammonium salt.

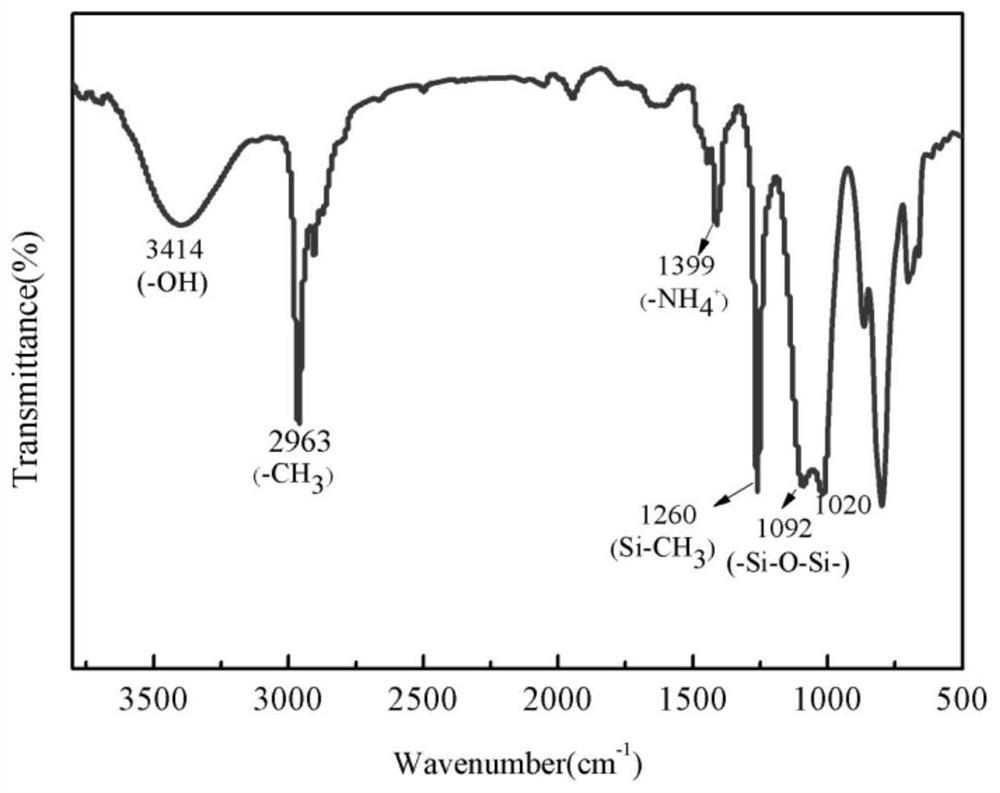

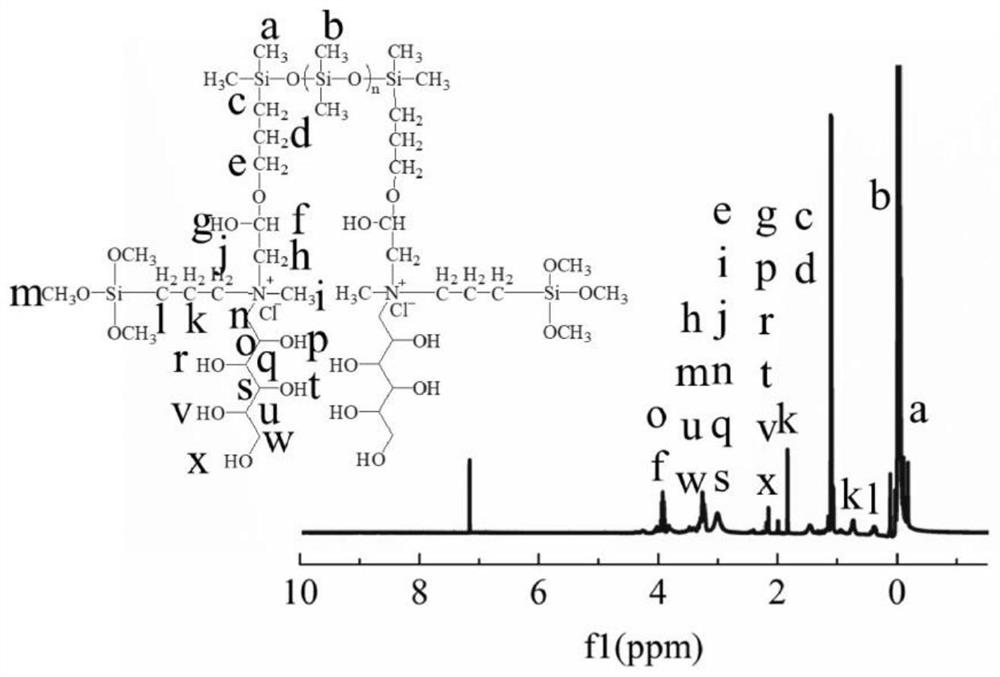

[0038] The chemical formula reaction process of the preparation method of the Bola type organic silicon quaternary a...

Embodiment 1

[0063] Step 1: Hydrosilylation, add 114g allyl glycidyl ether, Pt catalyst, pass N 2 , the temperature was raised to 50°C, 326.6g of tetramethyldisiloxane was added dropwise, and the dropwise addition was completed within 1h (molar ratio 1:2.3), then the temperature was raised to 90°C, and the temperature was kept for 3h. Raise the temperature of the colorless transparent liquid to 120°C, decompress (-0.09~0.1MPa) for 1 hour to remove the low boilers, and obtain a colorless transparent liquid, which is the epoxy double head F 2 D. 2 .

[0064] Step 2: Chain extension, 1000g D4 and 114.5g epoxy double head F 2 D. 2 , Solid tetramethylammonium hydroxide (0.02wt%) was added into a four-necked flask, the temperature was raised to 90-110°C, and the reaction was carried out for 10h, then the temperature was raised to 145-150°C, and the catalyst was decomposed for 0.5h. Then depressurize at -0.09~-0.1MPa for 0.5h to remove low boilers to obtain a colorless transparent viscous liq...

Embodiment 2

[0070] Step 1: Hydrosilylation, add 114g allyl glycidyl ether, Pt catalyst, pass N 2 , the temperature was raised to 50°C, 326.6g of tetramethyldisiloxane was added dropwise, and the dropwise addition was completed within 1h (molar ratio 1:2.3), then the temperature was raised to 90°C, and the temperature was kept for 3h. Raise the temperature of the colorless transparent liquid to 120°C, depressurize at -0.09~0.1MPa for 1 hour, remove the low boilers, and obtain a colorless transparent liquid, which is the epoxy double-capped F 2 D. 2 .

[0071] Step 2: Chain extension, 1000g D4 and 68.9g epoxy double head F 2 D. 2 , Solid tetramethylammonium hydroxide (0.02wt%) was added into a four-necked flask, the temperature was raised to 90-110°C, and the reaction was carried out for 10h, then the temperature was raised to 145-150°C, and the catalyst was decomposed for 0.5h. Then depressurize (-0.09~-0.1MPa) for 0.5h to remove low boilers to obtain a colorless transparent viscous li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com