Polyurethane microporous elastomer and preparation method thereof

A technology of microporous elastomers and elastomers, which is applied in the preparation of microporous elastomers and the field of polyether microporous elastomers, which can solve problems such as environmental impact, high density, and high overall density, so as to improve tolerance and reduce waste products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

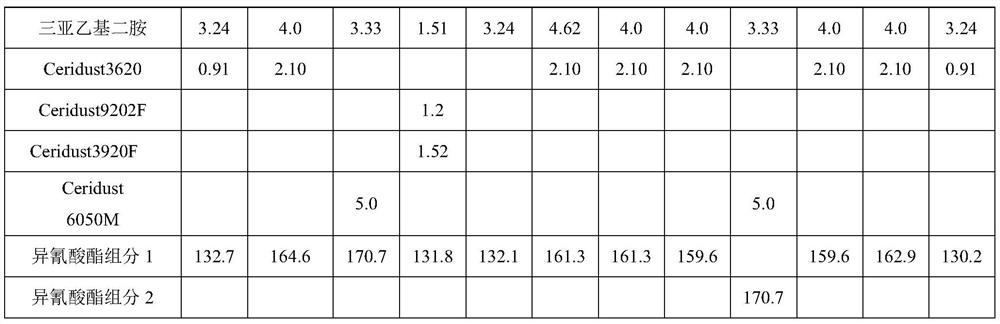

Examples

Embodiment Construction

[0043] The raw materials used in embodiment and comparative example are as follows:

[0044] Diphenylmethane diisocyanate, MDI-100, Wanhua Chemical;

[0045] Modified MDI, CDMDI-100L, Wanhua Chemical;

[0046] Polyether polyol 1, starting from propylene glycol, polymerized with propylene oxide and capped with ethylene oxide, with an ethylene oxide content of 15% and a number average molecular weight of 4000;

[0047] Polyether polyol 2, starting from glycerol, polymerized with propylene oxide and capped with ethylene oxide, with an ethylene oxide content of 15% and a number average molecular weight of 6000;

[0048] Polyether polyol 3, starting from diethylene glycol, polymerized with propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 25%, and the number average molecular weight is 5000;

[0049] Polyether polyol 4, starting from triethanolamine, polymerized with propylene oxide and capped with ethylene oxide, the content of ethylene oxide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com