Method for preparing MCM-36 molecular sieve under mild conditions

A technology of MCM-36 and MCM-22, which is applied in the field of preparing MCM-36 molecular sieves, can solve the problems of destroying structural integrity and reducing the acidity of molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

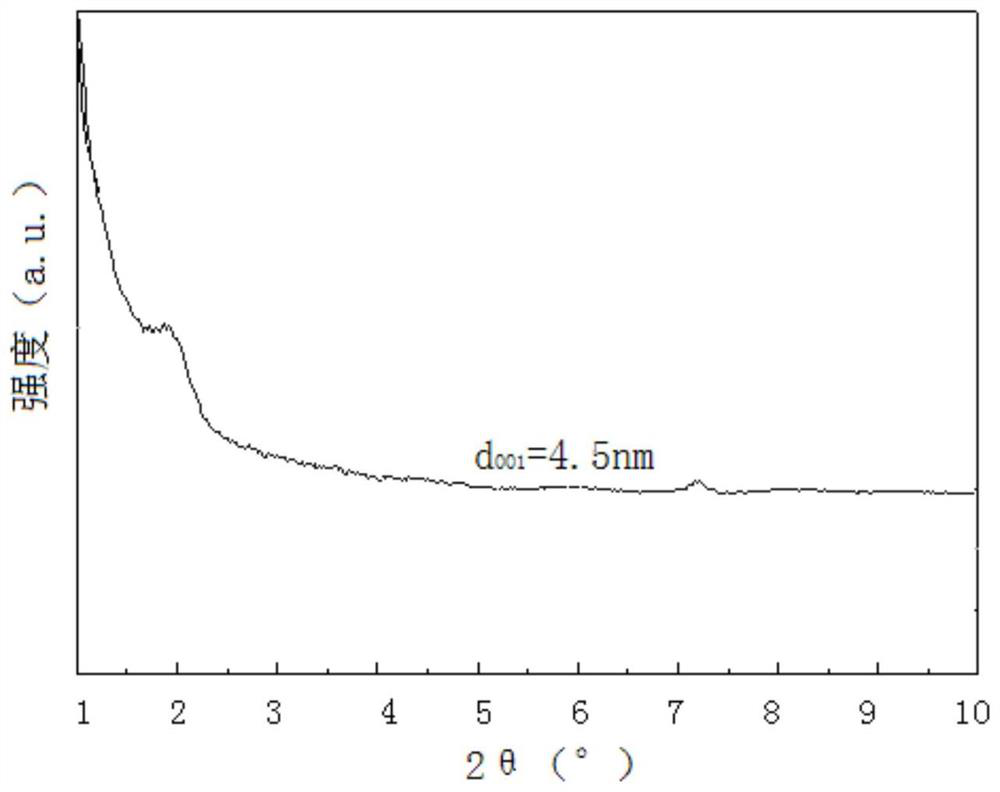

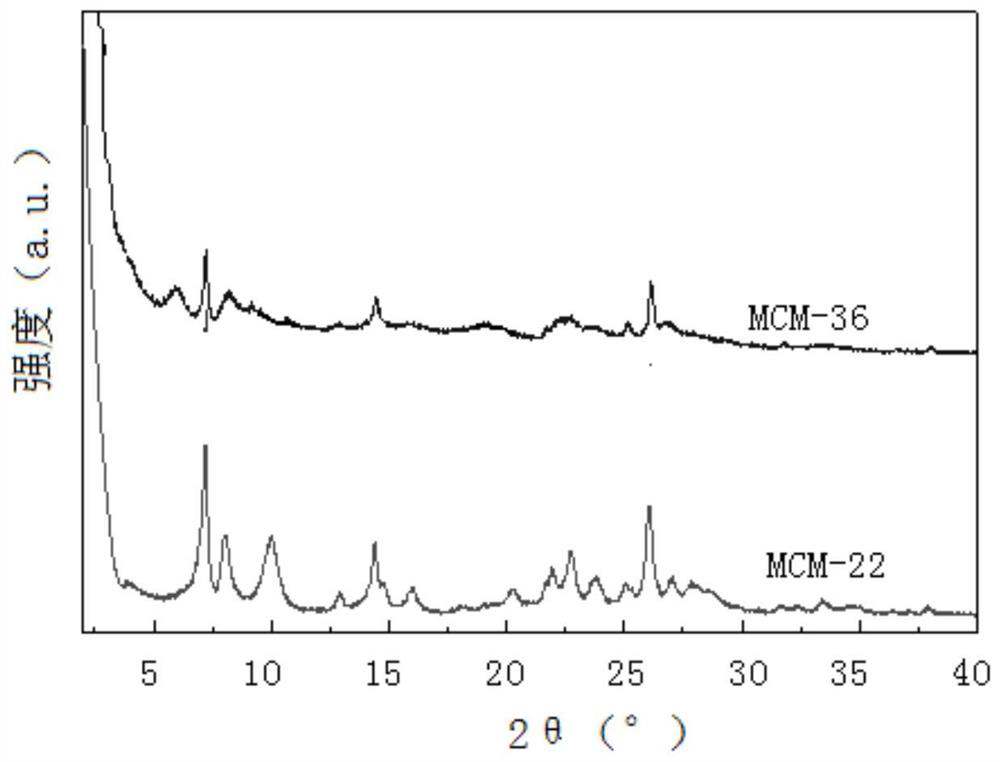

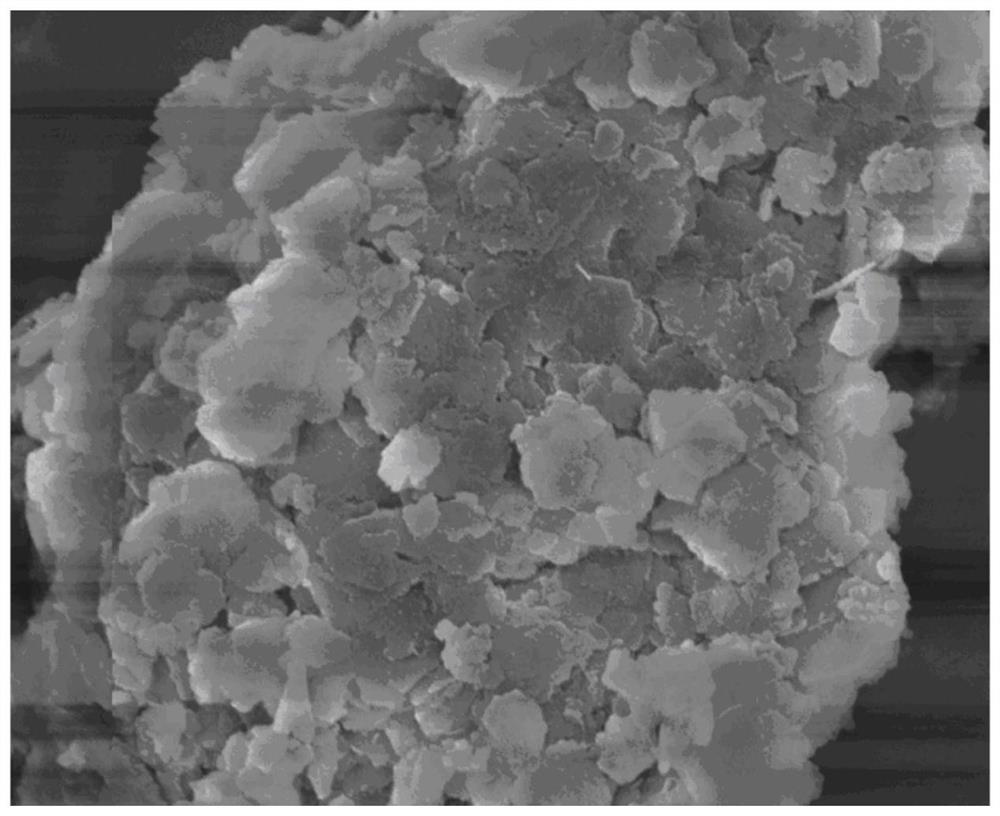

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of layered MCM-22(P)

[0026] According to the molar ratio: SiO 2 / Al 2 O 3 =50, OH – / SiO 2 =0.14, HMI / SiO 2 =0.35, H 2 O / SiO 2 =45, at room temperature, dissolve 0.36g NaOH in 50.32g deionized water, and then continue to add 0.30g NaAlO under stirring 2 , 9.34g SiO was added dropwise after it was completely dissolved 2 The sol continued to be stirred for 30mins, and then 2.18g HMI was added dropwise. The resulting mixed solution was moved into a stainless steel reactor with a 100mL polytetrafluoroethylene lining, installed in a homogeneous reactor, and stirred for 7 days at 60r / min at 150°C. . After the reaction was completed, the stainless steel reactor was removed from the homogeneous reactor and cooled in flowing cold water, separated by a centrifuge, washed with deionized water for several times to about pH=7, and dried in a drying oven at 60°C for 12 hours to obtain Layered MCM-22.

[0027] 2. Intercalation swelling of MCM-22(P)

[0028...

Embodiment 2

[0035] 1. Preparation of layered MCM-22(P)

[0036] This step is the same as step 1 of Example 1.

[0037] 2. Intercalation swelling of MCM-22(P)

[0038] According to the mass ratio: H 2 O / MCM-22(P)=40, TPAOH / MCM-22(P)=10, Gemini / MCM-22(P)=8, grind 1 g of layered MCM-22(P) into powder, 20 g Deionized water was added to a 150mL flask with magnetic stirring; 10g TPAOH, 20g H 2 O and 8g Gemini quaternary ammonium salt cationic surfactant were added to the beaker, poured into the aforementioned flask after sonication for 30mins and stirred for 5mins, and the pH value of the mixed solution in the flask was controlled between 8 and 9 by adding TPAOH, at 35°C The mixture was stirred in an oil bath for 16 h, washed with ethanol and deionized water by centrifugation, and finally dried in a drying oven at 35°C to obtain swollen MCM-22(P).

[0039] The structural formula of the Gemini quaternary ammonium salt cationic surfactant of the present embodiment is as follows:

[0040] ...

Embodiment 3

[0044] 1. Preparation of layered MCM-22(P)

[0045] This step is the same as step 1 of Example 1.

[0046] 2. Intercalation swelling of MCM-22(P)

[0047] According to the mass ratio: H 2 O / MCM-22(P)=45, TPAOH / MCM-22(P)=20, Gemini / MCM-22(P)=12, 1g of layered MCM-22(P), 25g ground into powder Deionized water was added to a 150mL flask with magnetic stirring; 20g TPAOH, 20g H 2 O and 12g Gemini quaternary ammonium salt cationic surfactant were added to the beaker, poured into the aforementioned flask after sonicating for 30mins and stirred for 5mins, and the pH value of the mixture in the flask was controlled between 8 and 9 by adding TPAOH, at 35°C The mixture was stirred in an oil bath for 16 h, washed with ethanol and deionized water by centrifugation, and finally dried in a drying oven at 35°C to obtain swollen MCM-22(P).

[0048] The structural formula of the Gemini quaternary ammonium salt cationic surfactant of the present embodiment is as follows:

[0049]

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com