Para-aramid and polyetherimide blended slurry, preparation method thereof and para-aramid coating diaphragm

A polyetherimide, para-aramid fiber technology, applied in electrical components, circuits, battery pack parts, etc., can solve the problem of reducing the porosity of the diaphragm, achieve good air permeability and heat resistance, avoid pores The effect of reducing the air permeability and avoiding the increase of the air permeability value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

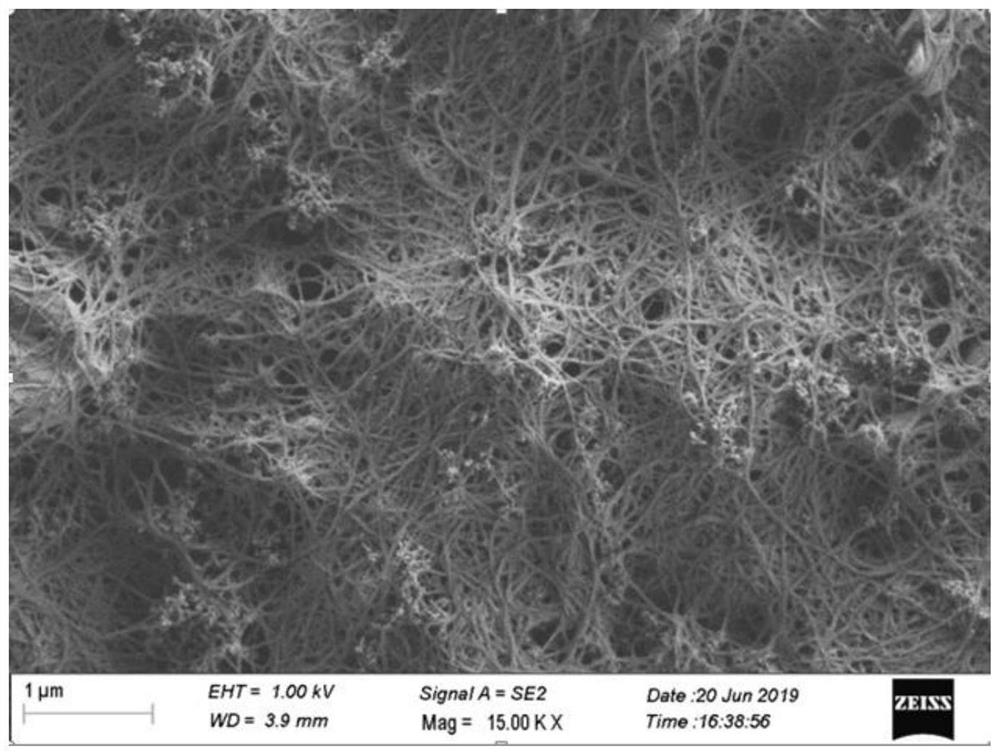

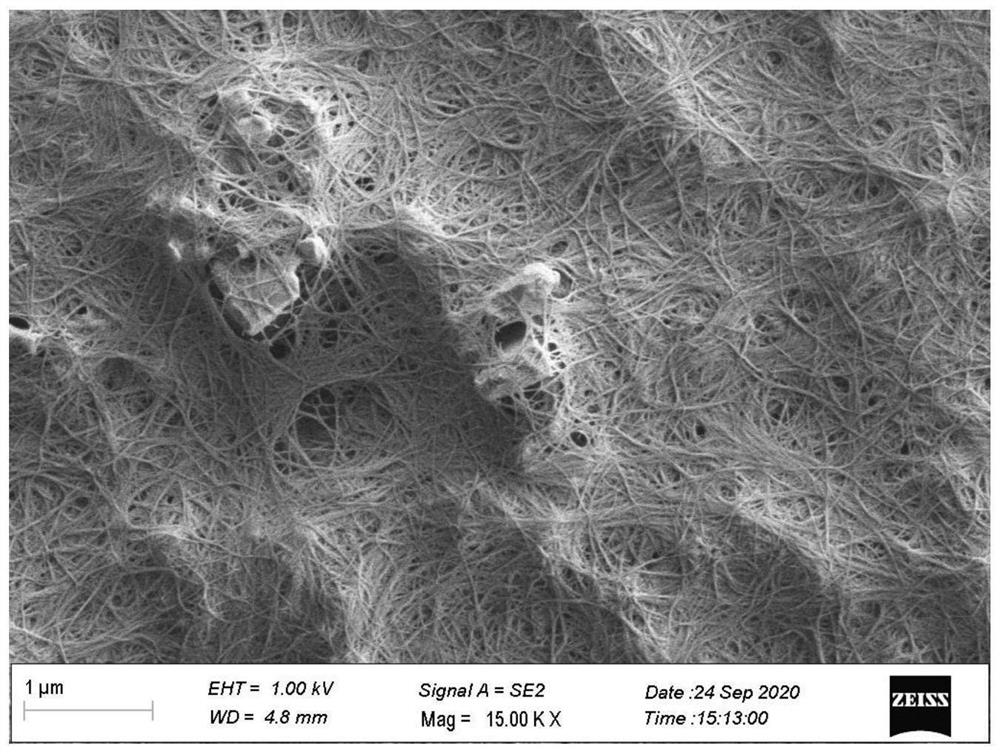

Image

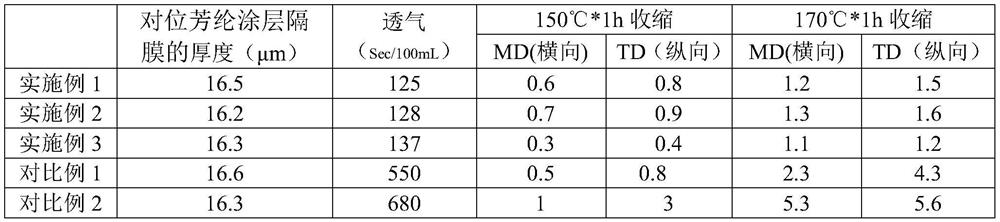

Examples

Embodiment 1

[0035] A preparation method of para-aramid and polyetherimide blend slurry, comprising the following steps:

[0036] Step 1: Add 8 parts by mass of calcium chloride to 92 parts by mass of N-methylpyrrolidone (NMP), raise the temperature to 60°C with a stirring jacket, and stir for 60 minutes until the calcium chloride is completely dissolved to obtain the first mixture solution;

[0037] Step 2: Cool the first mixed solution obtained in step 1 to room temperature, then add polytetramethylene glycol to the first mixed solution and stir evenly with a paddle-type agitator for 5 minutes, turn off the rotation, and paddle-type The revolution speed of the agitator is 35r / min (the agitator in the agitator is a paddle type, which is generally relatively large, and the stirring speed is relatively slow, which is called revolution. There are small dispersing discs in the paddle type stirring blade, which will follow the stirring The device revolves, and it also rotates during the revol...

Embodiment 2

[0046] A preparation method of para-aramid and polyetherimide blend slurry, comprising the following steps:

[0047] Step 1: Add 11 parts by mass of calcium chloride to 89 parts by mass of N-methylpyrrolidone (NMP), raise the temperature to 70°C with a stirring jacket, and stir for 60 minutes until the calcium chloride is completely dissolved to obtain the first mixture solution;

[0048] Step 2: Cool the first mixed solution obtained in step 1 to room temperature, then add polytetramethylene glycol to the first mixed solution and stir evenly with a paddle stirrer for 7 minutes, turn off the rotation, and the revolution speed is 35r / min, then add gas-phase nano-ceramic particles and stir evenly, the revolution speed is 40r / min, the rotation speed is 2000r / min, the stirring time is 35min, and finally add the pin-type nano-sand mill for sanding, the sanding speed The setting is 900r / min, and the sanding time is 17min; in terms of parts by mass, the ratio of the first mixed solu...

Embodiment 3

[0054] A preparation method of para-aramid and polyetherimide blend slurry, comprising the following steps:

[0055] Step 1: Add 15 parts by mass of calcium chloride to 85 parts by mass of N-methylpyrrolidone (NMP), raise the temperature to 80° C. with a stirring jacket, and stir until the calcium chloride is completely dissolved to obtain the first mixed solution;

[0056] Step 2: Cool the first mixed solution obtained in step 1 to room temperature, then add polytetramethylene glycol to the first mixed solution and stir evenly, the stirring time is 10 minutes, turn off the rotation, the revolution speed is 35r / min, and then add the gas phase The nano-ceramic particles are stirred evenly, the stirring revolution speed is 40r / min, the rotation speed is 2000r / min, the stirring time is 40min, and finally put into the pin-type nano-sand mill for sanding, and the sanding speed is set at 900r / min. The sanding time is 20 minutes; in terms of parts by mass, the ratio of the first mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com