Method of printing and in situ reduction of graphene

A technology of graphene and graphene ink, which is applied in the field of materials, can solve the problems of etching transfer, inability to tile and disperse, and high production cost, and achieve the effect of sufficient reduction process, novel preparation path, and simple reduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A normal temperature reaction in-situ reduction graphene circuit pattern, the preparation process of which comprises the following steps:

[0041] (1) Use graphene oxide and deionized water as raw materials, 30KHz ultrasonic in a water bath for 1 hour, prepare graphene oxide ink, the mass fraction of graphene oxide is 0.5% (the consumption ratio of graphene oxide and water is 5.0 mg: 1.0mL), the viscosity is 10cp, and the surface tension is 30mN / m.

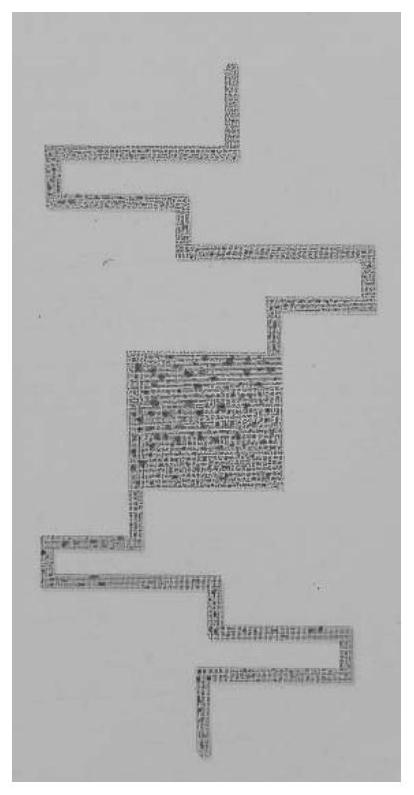

[0042] figure 1 It is a picture of the graphene oxide ink prepared in Example 1 of the present invention. The graphene oxide ink is stable and can be stored for a long time.

[0043] (2) Clean the PET flexible substrate by immersing it in ethanol solution, take it out, wipe it dry with dust-free paper, and place it in an oven at 60°C for 30 minutes to dry.

[0044](3) Wash the liquid storage tank of the inkjet printer (MicroFab Jetlab 4) for 3 times with deionized water, and observe whether the liquid at the nozzle (80 μm...

Embodiment 2

[0049] A kind of thick graphene circuit pattern of normal temperature reaction in-situ reduction, its preparation process comprises the following steps:

[0050] (1) Use graphene oxide and deionized water as raw materials, use an emulsifier, rotate at 5000rpm, stir for 30min, prepare graphene oxide ink, the mass fraction of graphene oxide is 1% (that is, the consumption ratio of graphene oxide and water 10.0mg: 1.0mL), the viscosity is 30cp, and the surface tension is 70mN / m.

[0051] (2) Soak the PET flexible substrate in pure water for cleaning, take it out and dry it with a dust-free paper.

[0052] (3) Wash the liquid storage tank of the inkjet printer (MicroFab Jetlab 4) for 3 times with deionized water, and observe whether the liquid at the nozzle (80 μm) is a uniform and elongated fluid. When it is observed that the nozzle has no fibers or ink stains, the prepared graphene oxide solution can be injected into the No. 1 liquid storage tank, and the printing parameters of...

Embodiment 3

[0059] A graphene pattern reduced in situ by normal temperature reaction, the preparation process of which comprises the following steps:

[0060] (1) Use graphene oxide and a solvent as raw materials, wherein the solvent is a mixed solvent of water and ethanol, and the volume ratio of water and ethanol is 9:1. Ultrasound at 30KHz in a water bath for 1 hour at 30°C to prepare a graphene oxide ink with a mass fraction of graphene oxide of 1% (that is, the ratio of graphene oxide to water is 10.0mg: 1.0mL) and a viscosity of 30cp. The tension is 70mN / m.

[0061] (2) Wash the liquid storage tank of the inkjet printer (model MicroFab Jetlab 4) with deionized water for 3 times, and observe whether the liquid at the nozzle (80 μm) is a uniform and slender fluid. When it is observed that the nozzle has no fibers or ink stains, the prepared graphene oxide solution can be injected into the No. 1 liquid storage tank, and the printing parameters of the inkjet printer can be adjusted. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com