Mold conveying device for mechanical production

A technology of transportation device and mold placing rack, which is applied in the direction of transportation and packaging, unloading device, and cover with auxiliary device, etc., which can solve the problems of mold scratches, easy shaking of molds, and easy scratches between molds, etc. To achieve the effect of improving stability and reducing reverse force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

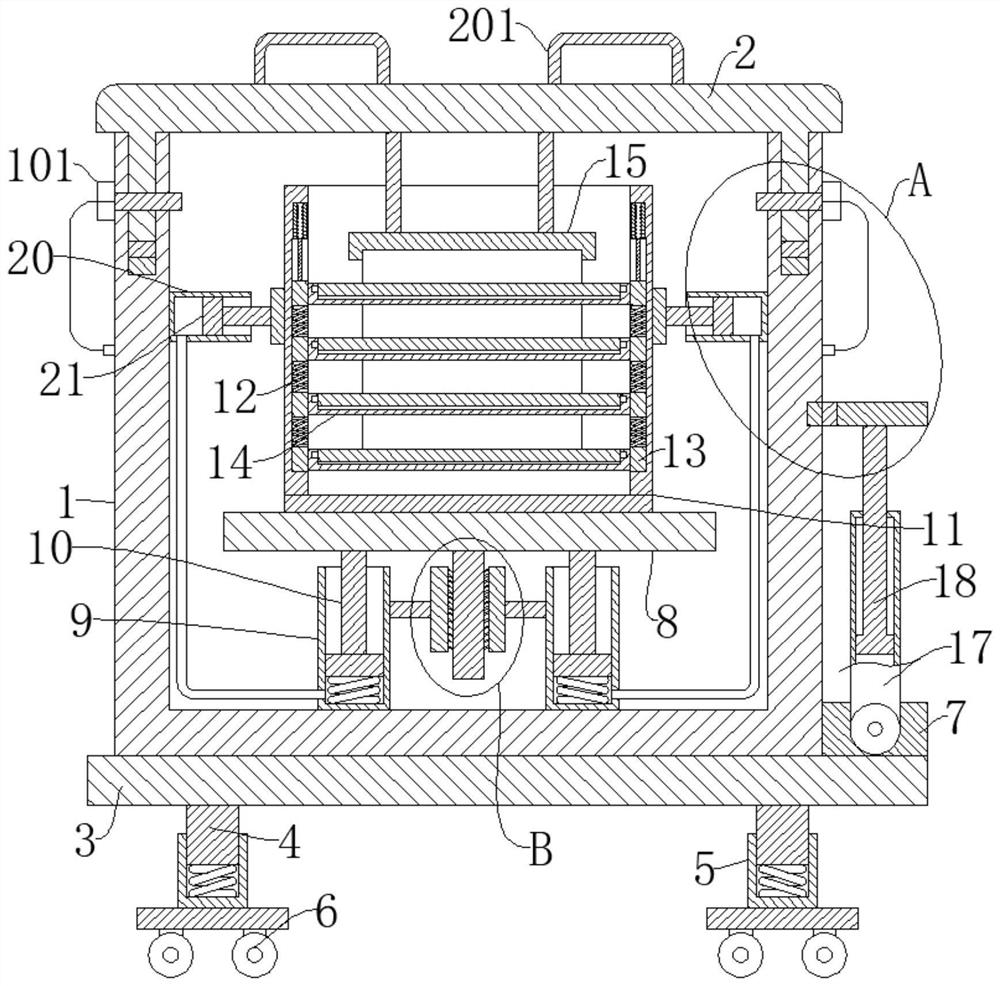

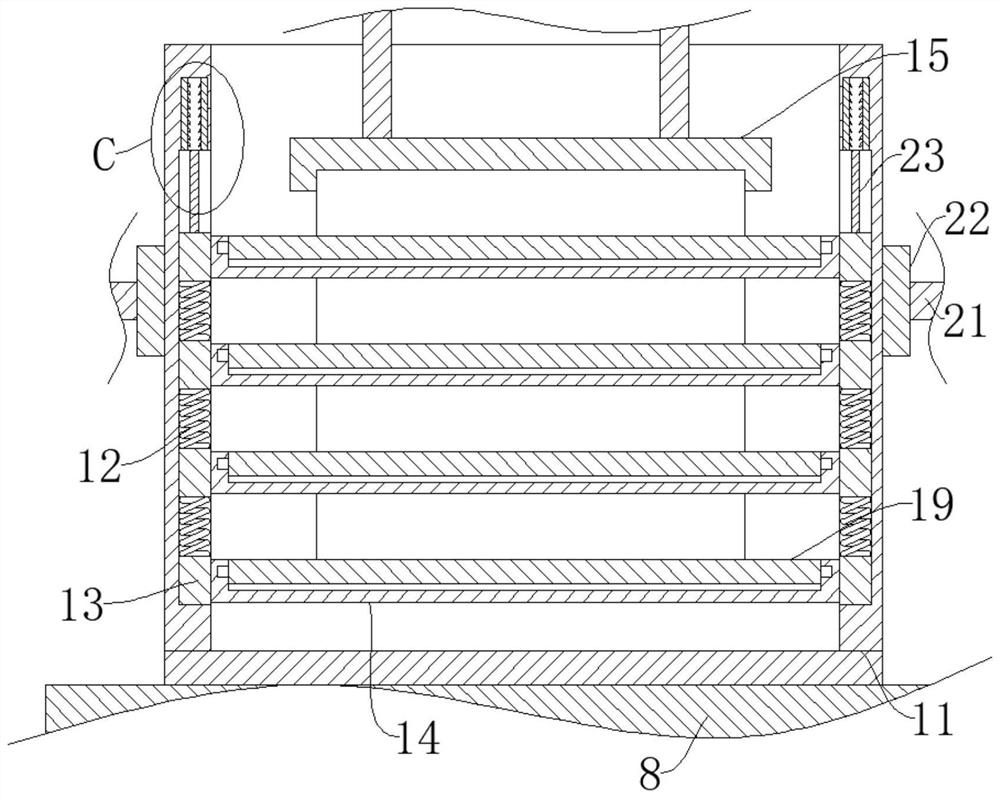

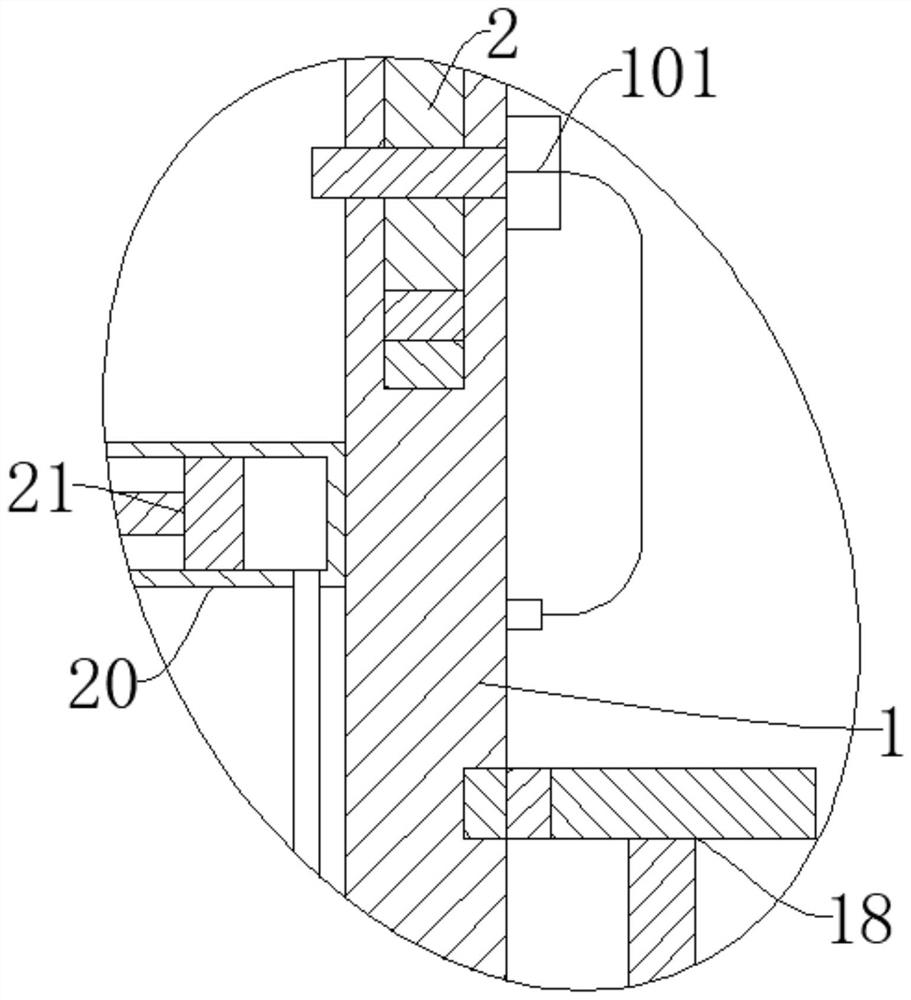

Embodiment 1

[0029] refer to Figure 1-6, a mold transportation device for mechanical production, comprising a transport case 1 and a base 3, the transport case 1 is fixedly connected to the base 3, the lower end of the base 3 is provided with a moving wheel 6, the transport case 1 is slidably connected with a case cover 2, and the transport case 1. The box cover 2 is fixedly connected with the first magnetic block and the second magnetic block that match each other. The transport box 1 and the box cover 2 are detachably connected by bolts 101. The inner bottom of the transport box 1 is fixedly connected with a supporting air supply mechanism, the upper end of the supporting air supply mechanism is fixedly connected with a moving plate 8, and the moving plate 8 is connected with a mold placing frame 11, and the two sides of the mold placing frame 11 are provided with chutes, and slidingly connected with a plurality of sliders 13 in the chute, every two Each slider 13 is fixedly connected w...

Embodiment 2

[0032] refer to figure 1 , a mold transportation device for mechanical production, which is basically the same as that of Embodiment 1, furthermore: the support air supply mechanism includes a first cylinder 9, a first piston 10, a first spring, and the connection between the first cylinder 9 and the transport box 1 The first spring is fixedly connected in the first cylinder 9, the first piston 10 is slidably connected in the first cylinder 9, and is fixedly connected with the first spring, and the end of the first piston 10 away from the first spring is connected with the moving plate 8 fixed connection, when the mold is put into the mold placing frame 11, cover the box cover 2, under the action of the fixed plate 15, the moving plate 8 moves downward, and the first piston 10 transports the gas in the first cylinder 9 through the air pipe Into the pneumatic clamping mechanism, deliver gas to the pneumatic clamping mechanism.

Embodiment 3

[0034] refer to Figure 1-3 , a mold transportation device for mechanical production, which is basically the same as that of Embodiment 1, furthermore: the pneumatic clamping mechanism includes a second cylinder 20 and a second piston 21, and the second cylinder 20 is fixedly connected to both sides of the transportation box 1 , the second piston 21 is slidingly connected in the second cylinder 20, the end of the second piston 21 away from the inner wall of the transport case 1 is connected with a splint 22, the air inlet of the second cylinder 20 is connected with the air outlet of the first cylinder 9 through a trachea, The gas delivered to the second cylinder 20 through the air pipe makes the second piston 21 move towards the mold placement frame 11, so that the splint 22 is in close contact with the mold placement frame 11, clamping and fixing it, and improving the stability during transportation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com