Metal part polishing device

A polishing device and technology for metal parts, applied in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve problems such as incomplete polishing, polishing settings that cannot be polished, excessive polishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

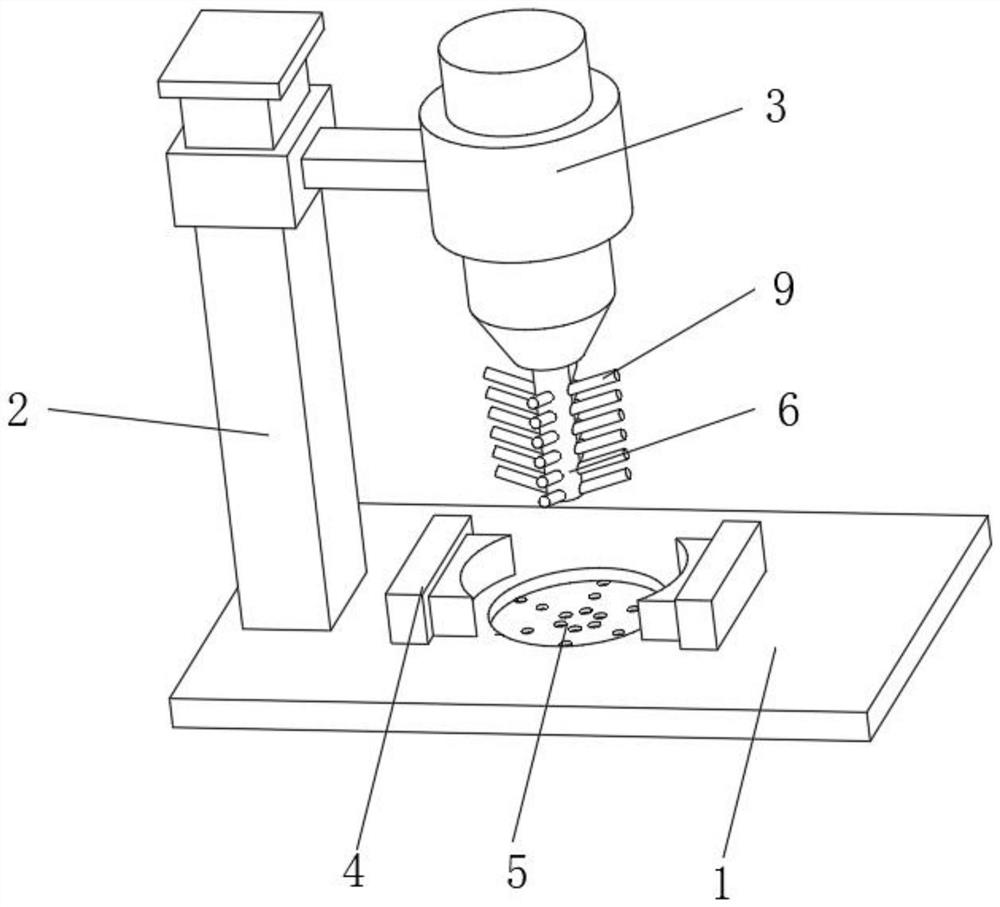

[0038] Such as Figure 1-2 As shown, the present invention provides a technical solution: a metal piece polishing device, including a processing base plate 1, an adjustment bracket 2 is fixedly connected to the middle position on the left side of the top of the processing base plate 1, and a polishing driver 3 is sleeved on the outside of the adjustment bracket 2 The top of the processing base plate 1 and the two sides close to the middle position are fixedly connected with the support fixture 4, the top of the processing base plate 1 and the middle position of the support fixture 4 are fixedly connected with the dust filter 5, and the bottom output end of the polishing driver 3 is fixedly connected with The polishing connecting shaft 6, the outer side of the polishing connecting shaft 6 is uniformly provided with an adjustment groove 7, the inside of the adjustment groove 7 is fixedly connected with an auxiliary shaft block 8, and the end of the auxiliary shaft block 8 located...

Embodiment 2

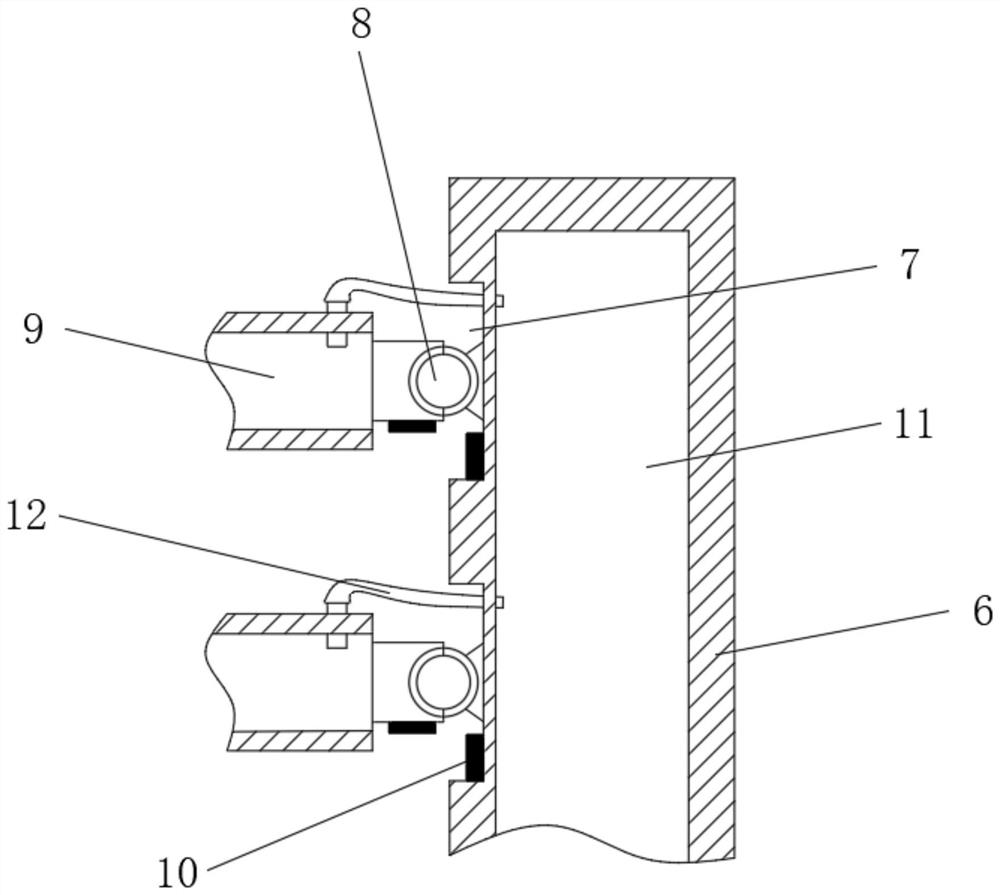

[0041] Such as Figure 3-4 As shown in and 6, on the basis of Embodiment 1, the present invention provides a kind of technical scheme: a kind of metal parts polishing device, polishing knife bar mechanism 9 comprises outer drawing sleeve bar 91, the right side of outer drawing sleeve bar 91 An adjustment insertion rod 92 runs through and is slidably connected, and one end of the adjustment insertion rod 92 located outside the outer stretching sleeve rod 91 is rotatably connected with the auxiliary shaft block 8 .

[0042] An air pressure control groove 93 is opened inside the outer stretching sleeve rod 91 , and an air pressure conduction inner groove 94 is opened inside the adjusting insert rod 92 .

[0043] The air pressure control groove 93 communicates with the air pressure conduction inner groove 94 , and the input end of the conduction through pipe 12 communicates with the air pressure conduction inner groove 94 .

[0044] One end of the adjusting inserting rod 92 locat...

Embodiment 3

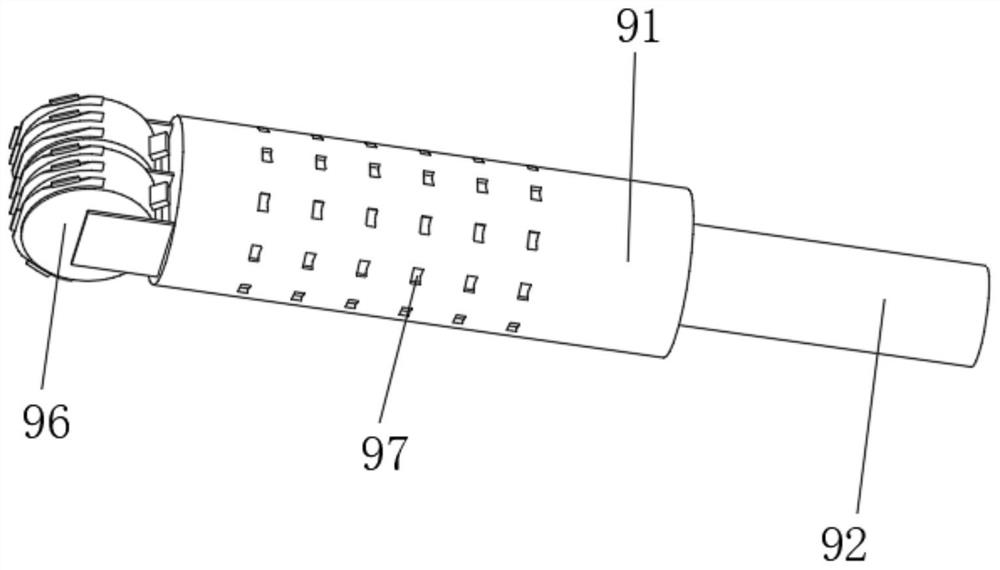

[0047] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a metal piece polishing device, the blade assembly 96 includes a tool holder 961, the right side of the tool holder and the outer stretching sleeve rod 91 It is fixedly connected, and the middle position of the cutter support 961 is connected with a polishing traveling wheel 962 through a driving coupling shaft 963 for rotation.

[0048] The left surface of the polishing walking wheel 962 is evenly and fixedly connected with a polishing blade 964, the polishing blade 964 is set corresponding to the circular surface of the polishing walking wheel 962, and the outer surface of the polishing blade 964 is evenly provided with grooves.

[0049] The position of the groove on the outer surface of the polishing blade 964 is fixedly connected with a walking buffer block 965, and the height of the walking buffer block 965 is the same as that of the highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com