Sustained-release type orally disintegrating film with excellant oral mucoadhesion and the manufacturing method thereof

A technology of oral disintegration and oral mucosa, which is applied in the directions of medical preparations with non-active ingredients, medical preparations containing active ingredients, and oral care, etc. The effect of increasing the disintegration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] [Step 1: Prepare Materials]

[0139] In addition to the material used in Comparative Example 1, chitosan was used as a positively charged product that was deacetylated with sodium hydroxide in commercially available products, more specifically, as Glycol chitosan (Glycol chitosan, GCS) purchased products from VITATRA (USA).

[0140] [Step 2: Adjust the mixing ratio]

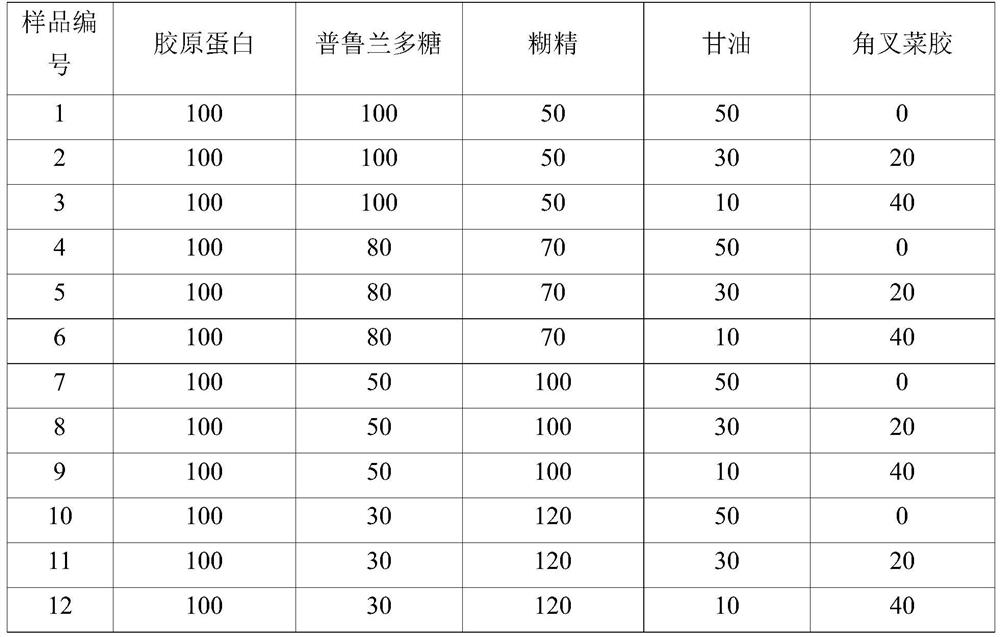

[0141] Using the prepared material, based on pure collagen content 100 mg, the basic composition ratio of the main components affecting the physical properties of a sample product containing chitosan, a film with a final weight of 300 mg, was investigated.

[0142] In Example 1, the same material composition ratio as Comparative Example 1 was used, but the physical property change during drying was first confirmed under the conditions of [Table 6] to find the optimum mixing ratio according to the content of chitosan.

[0143] 【Table 6】

[0144] [Unit: 300mg]

[0145]

[0146] It was shown that in th...

experiment example

[0158] [Sustained release (disintegration) measurement]

[0159] Based on the compositions determined by the above-mentioned Comparative Example 1 and Example 1, 6 samples of Comparative Example and 6 samples of Example were prepared, respectively, and then three samples each of Comparative Example 1 and Example 1 were thinly coated with B Base cellulose (Ethylcellulose), so as to compare the difference in disintegration speed.

[0160] As a matter of course, all samples were prepared in the same process sequence as previously prepared, with the only difference being whether the ethylcellulose was spray coated or not.

[0161] Dissolve ethyl cellulose in purified water at a ratio of 10, put it into a small spray sprayer, spray three times at a distance of about 30 cm from the petri dish, and then completely dry it in a convection oven at 50°C for 30 minutes, so that the final Prepare samples for disintegration testing.

[0162] The device for the disintegration test is confi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com