Application of highland barley fermentation extract

An extract, highland barley technology, applied in the application field of highland barley fermented extract, can solve the problems of repairing aging skin without micro-ecology on the skin surface, achieve good application prospects, promote proliferation, and reduce the effect of ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of highland barley fermentation product filtrate

[0033] The base material of this fermentation product is highland barley, which is produced in Lhasa, Tibet, in the Pan-Himalaya region. The highland barley grains containing the bran are washed with deionized water, dried, and then beaten by a flouring machine, and passed through a 20-100 mesh sieve to obtain highland barley flour. The highland barley powder is mixed with deionized water, and the content of the highland barley powder in the fermentation medium / culture solution is 4wt%; after the high temperature and high pressure sterilization is cooled, Saccharomyces cerevisiae is fermented under the conditions of 26~30° C. and 150~250rpm 48 hours.

[0034] Preparation of highland barley fermentation filtrate:

[0035] (1) Centrifuge the fermentation product for 10-30 min at 4-10 °C and 6000 rpm, and take the supernatant;

[0036] (2) Adjust pH to 5.0~7.0, after 30~60min of water bath at 80~90...

Embodiment 2

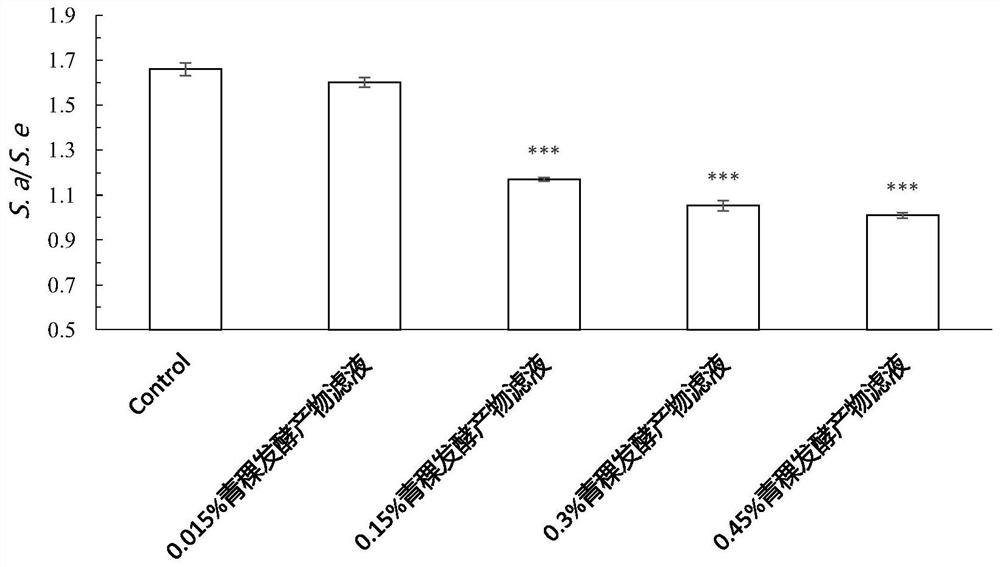

[0041] Example 2 Influence of highland barley fermentation extract on surface flora

[0042] (1) Experimental materials

[0043] 1. Experimental strains

[0044] Staphylococcus epidermidis S.e (Staphylococcus epidermidis), Staphylococcus aureus S.a (Staphylococcus aureus).

[0045] 2. Culture medium

[0046] LB medium: 0.5% yeast powder, 1.0% tryptone, 1.0% NaCl, the balance is water, and the percentages are mass percentages. 121 ℃, 20min high temperature autoclave sterilization after cooling for use.

[0047] 3. Sample Information

[0048] Blank sample (Control): sterile physiological saline: 0.9% NaCl, the balance is water, and the percentage is mass percentage. 121 ℃, 20min high temperature autoclave sterilization after cooling for use.

[0049] Experimental sample: the highland barley fermentation product filtrate obtained in Example 1, wherein the solid content is 1.5 wt%.

[0050] (2) Experimental steps

[0051] 1. Put the preserved S.a and S.e (single colony or ...

Embodiment 3

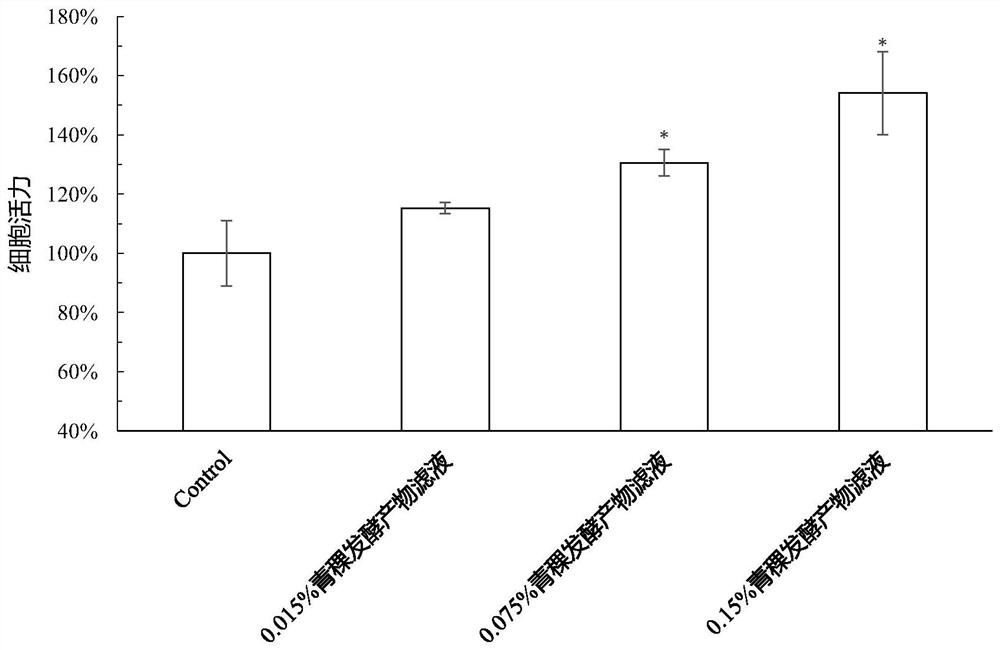

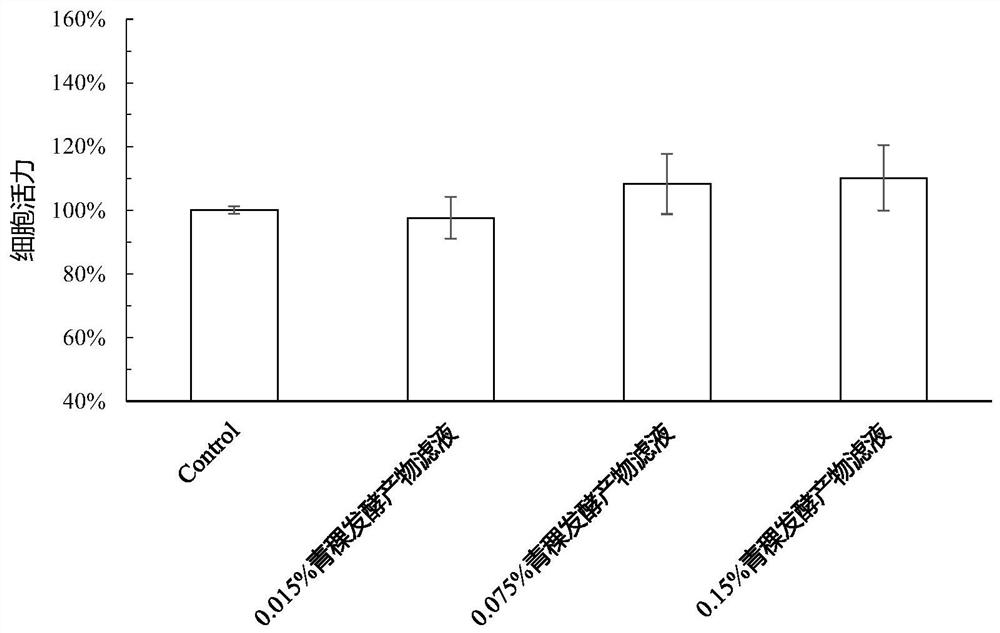

[0056] Example 3 Cell proliferation of highland barley fermentation products

[0057] (1) Experimental materials

[0058] Cells: dermal fibroblasts Fibroblast, human immortalized epidermal cells HaCaT.

[0059] Experimental sample: The highland barley fermentation product filtrate was prepared into solutions of different concentrations with deionized water, and the highland barley fermentation product filtrate of each concentration was added to the serum-free DMEM or MEM medium required for different cell growth to dry the highland barley fermentation product filtrate in the medium. The substance content is 0.015%, 0.075% and 0.15%, and the percentages are mass percentages.

[0060] (2) Experimental method

[0061] The highland barley fermentation product filtrate was prepared into solutions of different concentrations with deionized water, and added to the culture medium of human fibroblasts. The deionized water without the sample was used as a blank control. The absorbanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com