Cl-modified GQD/ZnO/acidified attapulgite nano-composite antibacterial agent and preparation method thereof

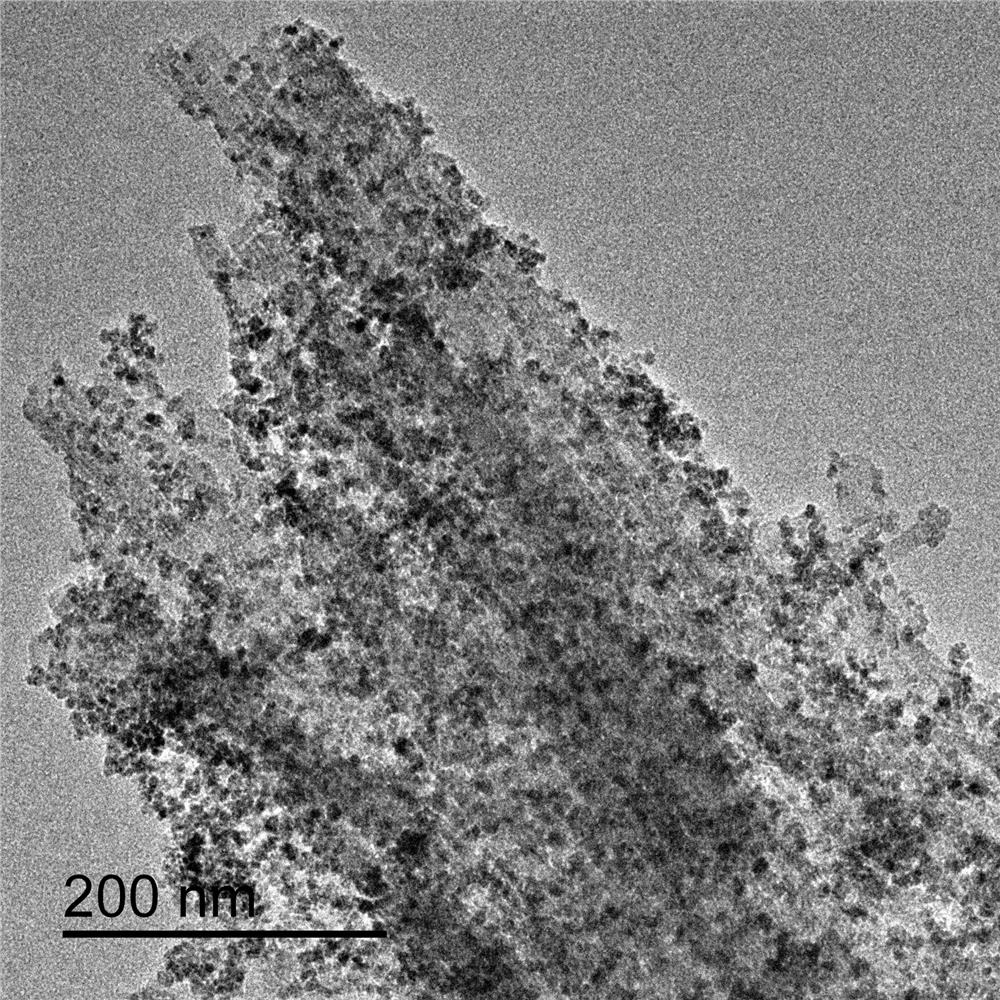

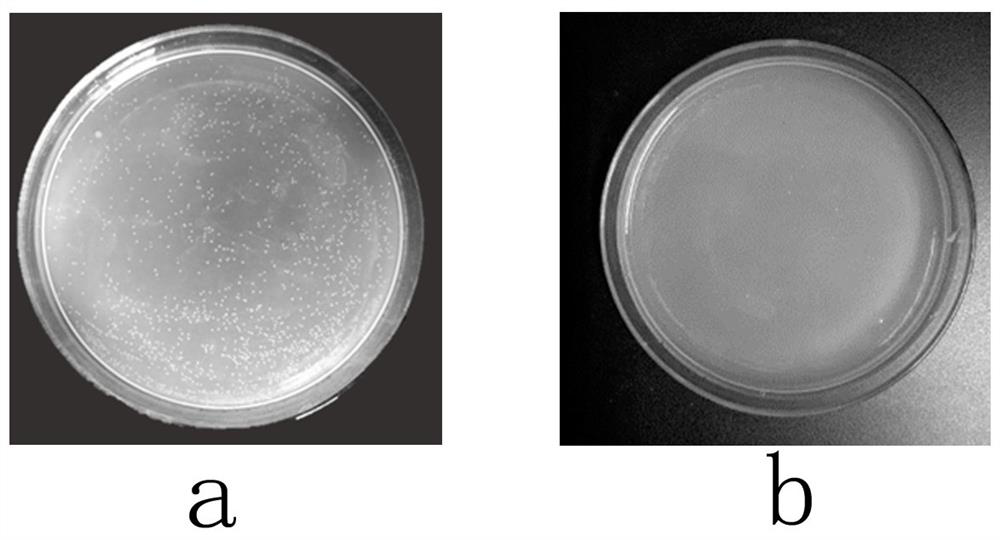

An acidified attapulgite and nanocomposite technology, applied in the fields of botanical equipment and methods, nanotechnology, nanotechnology, etc., can solve the problems of large specific surface area of quantum dots, easy to agglomerate, affect antibacterial properties, etc., and achieve high antibacterial activity. The effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 4g of attapulgite and put it into a 5mol / L hydrochloric acid solution. After heating in a water bath at 70°C for 10 hours, the product is washed with distilled water for 3 times, and the upper layer is removed by standing each time to wash the attapulgite solution with water until neutral. Finally, centrifuge and dry the solid precipitate to obtain acidified attapulgite.

[0024] After heating 3 g of citric acid (CA) at 200 °C for 30 min to turn dark orange, NaOH aqueous solution was added to adjust the pH to neutral to obtain an aqueous solution of GQDs. Take 130mg of GQD in 50ml of HCl and heat in a water bath at 65°C for 2h to obtain chlorine-modified graphene quantum dots.

[0025] Weigh 1g of zinc acetate dihydrate and 0.05g of chlorine-modified graphene quantum dots and disperse them in 100 mL of absolute ethanol, stir well, add 400 mg of AP, pour into a three-necked flask, and heat in a water bath at 60°C for 1.5h , to obtain zinc, GQD-Cl, acidified attapu...

Embodiment 2

[0029] Weigh 7g of attapulgite and put it into 8mol / L hydrochloric acid solution. After heating in a water bath at 50°C for 25h, the product is washed with distilled water 3 times, and the upper layer is removed by standing each time, so as to wash the attapulgite solution with water until neutral. Finally centrifuged,

[0030] Take the solid precipitate and dry it to obtain the acidified attapulgite.

[0031] After heating 2 g of citric acid (CA) at 200 °C for 30 min to turn dark orange, NaOH aqueous solution was added to adjust the pH to neutral to obtain an aqueous solution of GQDs. Take 120mg of GQD in 50ml of HCl and heat in a water bath at 60°C for 2h to obtain chlorine-modified graphene quantum dots.

[0032] Weigh 1 g of zinc acetate dihydrate and 0.01 g of chlorine-modified graphene quantum dots and disperse them in 100 mL of absolute ethanol. After stirring evenly, add 600 mg of AP, pour into a three-necked flask, and heat in a water bath at 80°C for 3 h. The mixed...

Embodiment 3

[0034] Weigh 6g of attapulgite and put it into 7mol / L hydrochloric acid solution. After heating in a water bath at 60°C for 20 hours, the product is washed with distilled water three times, and the upper clear night is removed by standing each time, so as to wash the attapulgite solution with water until neutral. Finally, centrifuge and dry the solid precipitate to obtain acidified attapulgite.

[0035] After heating 5 g of citric acid (CA) at 200 °C for 30 min to turn dark orange, NaOH aqueous solution was added to adjust the pH to neutral to obtain an aqueous solution of GQDs. Take 140mg of GQD in 50ml of HCl, and heat in a water bath at 80°C for 2h to obtain chlorine-modified graphene quantum dots.

[0036]Weigh 1g of zinc acetate dihydrate and 0.04g of chlorine-modified graphene quantum dots and disperse them in 100 mL of absolute ethanol, stir well, add 500 mg of AP, pour into a three-necked flask, and heat in a water bath at 70°C for 2.5h , to obtain zinc, GQD-Cl, acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com