Catalyst and method for producing compound using same

A manufacturing method and catalyst technology, applied in the preparation of organic compounds, catalyst activation/preparation, carbon-based compound preparation, etc., can solve the problems of isobutene conversion rate increase, yield or selectivity decrease, etc., to achieve increased yield, The effect of improving process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

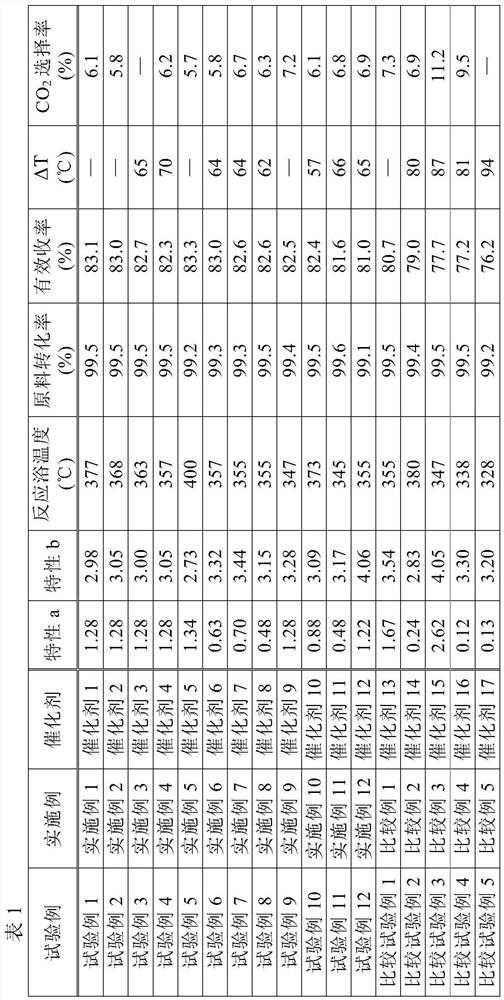

Examples

Embodiment 1

[0118] [Example 1] (preparation of catalyst 1)

[0119] 100 parts by mass of ammonium heptamolybdate was completely dissolved in 380 parts by mass of pure water heated to 80°C (mother liquid 1). Next, 3.7 parts by mass of cesium nitrate was dissolved in 42 mL of pure water, and added to mother liquor 1. Next, 34 parts by mass of iron nitrate, 103 parts by mass of cobalt nitrate, and 10 parts by mass of nickel nitrate were dissolved in 78 mL of pure water heated to 60° C., and added to mother liquor 1 . Next, 17 parts by mass of bismuth nitrate was dissolved in an aqueous solution of nitric acid prepared by adding 4.4 parts by mass of nitric acid (60% by mass) to 18 mL of pure water heated to 60°C, and added to Mother Liquor 1 . The mother liquor 1 was dried by a spray drying method, and the obtained dry powder was precalcined at 440° C. for 5 hours. Add 5% by mass to the calcined powder thus obtained (the atomic ratio calculated from the input raw materials is Mo:Bi:Fe:Co:N...

Embodiment 2

[0120] [Example 2] (preparation of catalyst 2)

[0121] 100 parts by mass of ammonium heptamolybdate was completely dissolved in 380 parts by mass of pure water heated to 80°C (mother liquid 1). Next, 3.7 parts by mass of cesium nitrate was dissolved in 42 mL of pure water, and added to mother liquor 1. Next, 37 parts by mass of iron nitrate, 99 parts by mass of cobalt nitrate, and 11 parts by mass of nickel nitrate were dissolved in 78 mL of pure water heated to 60° C., and added to Mother Liquor 1 . Next, 21 parts by mass of bismuth nitrate was dissolved in an aqueous nitric acid solution prepared by adding 5.4 parts by mass of nitric acid (60% by mass) to 23 mL of pure water heated to 60° C., and added to Mother Liquor 1 . The mother liquor 1 was dried by a spray drying method, and the obtained dry powder was precalcined at 440° C. for 5 hours. Add 5% by mass to the calcined powder thus obtained (atomic ratio calculated from the input raw materials is Mo:Bi:Fe:Co:Ni:Cs=1...

Embodiment 3

[0122] [Example 3] (preparation of catalyst 3)

[0123] 100 parts by mass of ammonium heptamolybdate was completely dissolved in 380 parts by mass of pure water heated to 80°C (mother liquid 1). Next, 3.7 parts by mass of cesium nitrate was dissolved in 42 mL of pure water, and added to mother liquor 1. Next, 37 parts by mass of iron nitrate, 99 parts by mass of cobalt nitrate, and 11 parts by mass of nickel nitrate were dissolved in 78 mL of pure water heated to 60° C., and added to Mother Liquor 1 . Next, 17 parts by mass of bismuth nitrate was dissolved in an aqueous solution of nitric acid prepared by adding 4.4 parts by mass of nitric acid (60% by mass) to 18 mL of pure water heated to 60°C, and added to Mother Liquor 1 . The mother liquor 1 was dried by a spray drying method, and the obtained dry powder was precalcined at 440° C. for 5 hours. Add 5% by mass to the calcined powder thus obtained (atomic ratio calculated from the input raw materials is Mo:Bi:Fe:Co:Ni:Cs=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com