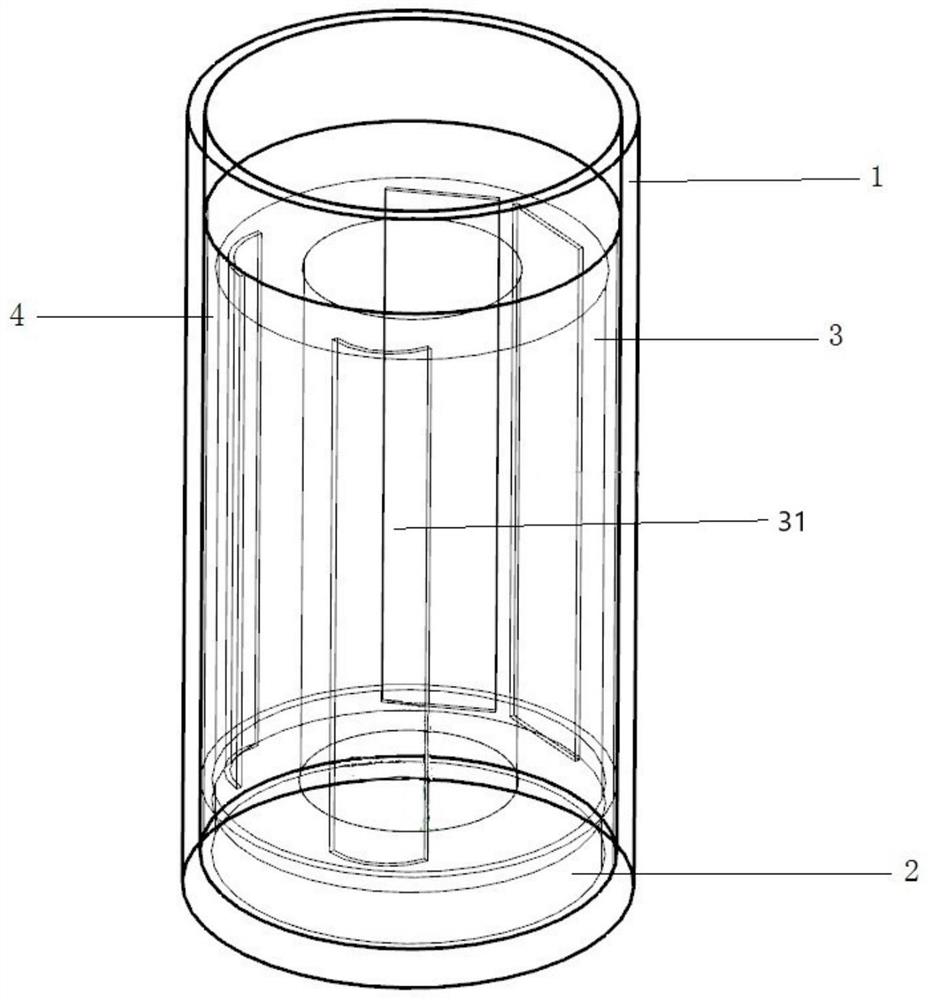

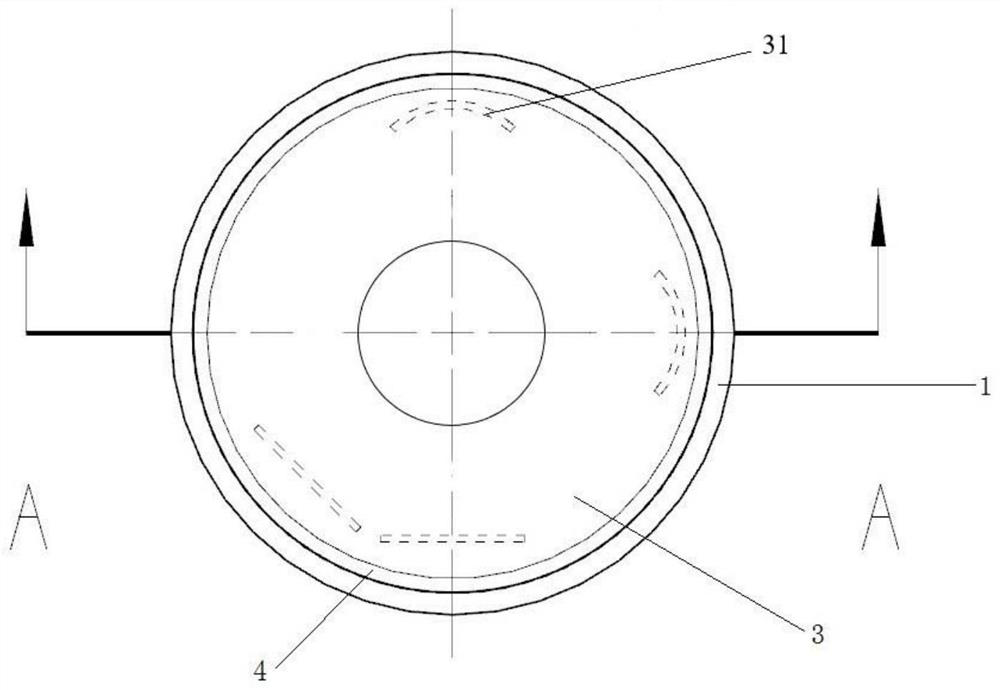

High-thermal-conductivity isothermal body temperature control irradiation device

An irradiation device and high thermal conductivity technology, which is applied in the field of nuclear power materials, can solve the problems of limited irradiation space, low use cost, and low thermal conductivity, and achieve the effects of uniform temperature distribution, increased temperature, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the samples to be irradiated are two 1 / 4 arc thin zirconium alloy claddings and two zirconium alloy plates respectively, and the irradiation temperature required for the test is 350°C. The thickness of the side wall of the irradiation capsule is 1.5mm, the thickness of the bottom of the irradiation capsule is 5mm, the thickness of the top cover is 10mm, the inner diameter of the irradiation capsule is 36mm, and the outer diameter is 39mm. The capsule is made of nuclear grade 6061 aluminum material. A pure copper circular isothermal body with an outer diameter of 33.4 mm and an inner diameter of 21 mm is placed inside the irradiation capsule. By adjusting the inner and outer diameters of the isothermal body, the calorific value of the pure copper isothermal body is adjusted to make the sample reach the target irradiation temperature. The lower end of the pure copper ring-shaped isothermal body is cushioned with a zirconia ceramic material block with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com