Retarder used in refractory material

A technology of refractory materials and retarders, applied in the field of retarders, can solve problems such as high temperature performance damage, construction failure, and insufficient construction time, and achieve the effects of system stability, delayed hydration speed, and good dispersion retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

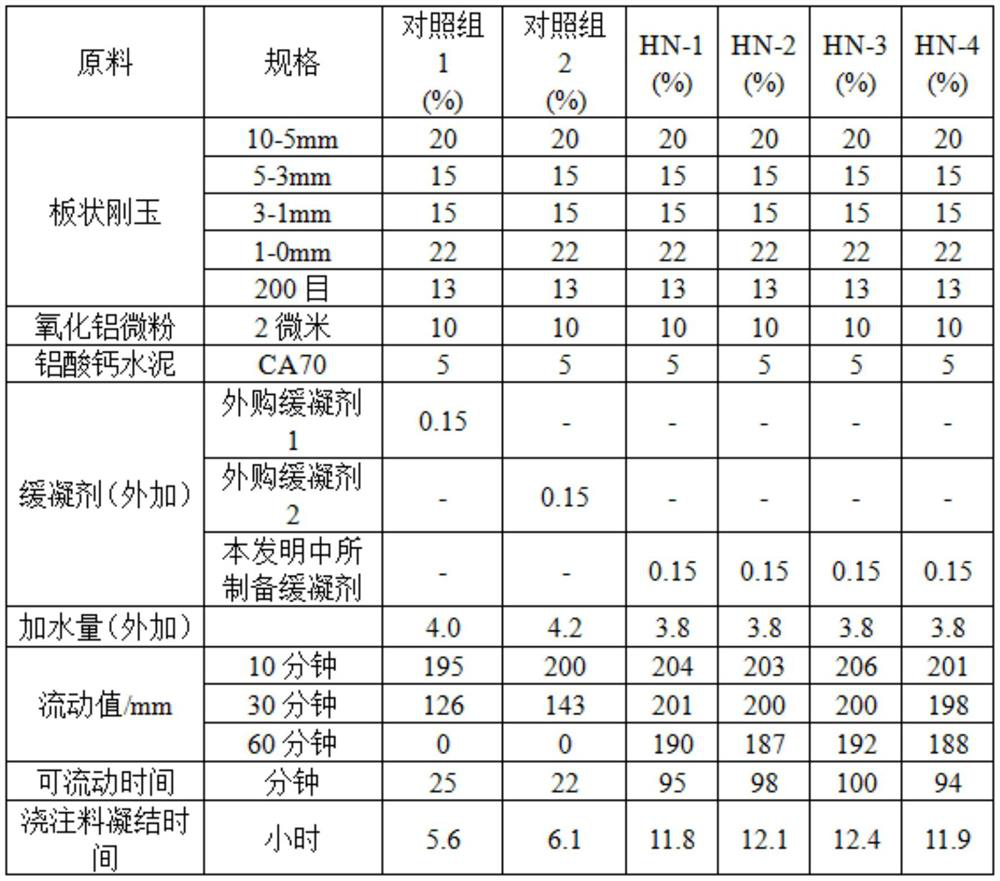

Examples

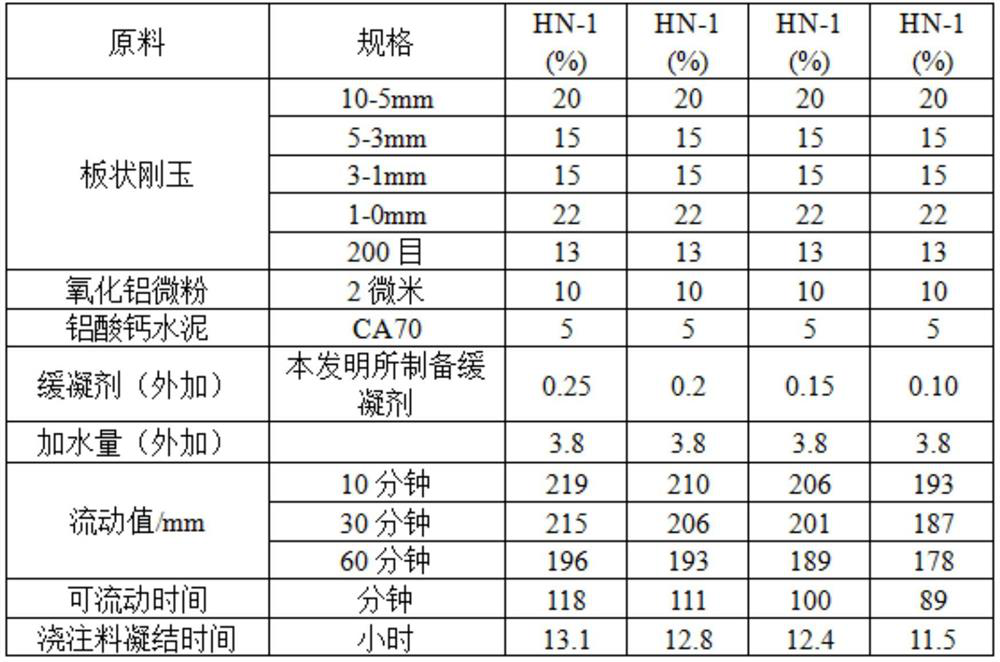

Embodiment 1

[0019] Weigh 10g (0.01mol) of polyneopentyl glycol adipate (molecular weight 1000), 10mL of N-methylpyrrolidone, 2.54g (0.005mol) of methylsilsesquioxane, add the in a three-neck flask. Stir at a constant speed with a stirrer, and heat up to 50° C.; add 4.45 g (0.02 mol) of isophorone diisocyanate after the temperature of the solution in the reaction vessel reaches 50° C. Then add the catalyst dibutyltin dilaurate (the amount accounts for 2% of the total mass of the reaction system), keep the temperature for 1 hour after the addition, then raise the temperature to 70° C., and keep the temperature for 4 hours. Add 1.04g (0.01mol) sodium bisulfite, strengthen the stirring, continue stirring for 1h, add water into the reaction kettle, and stir for 30min to obtain a retarder for refractory materials, named as HN-1.

Embodiment 2

[0021] Weigh 15g (0.01mol) of polytrimethylene adipate (molecular weight 1500), 15mL of N-methylpyrrolidone, 2.54g (0.005mol) of methylsilsesquioxane, and add them to a three-necked flask equipped with a reflux condenser . Stir at a constant speed with a stirrer, and raise the temperature to 50° C.; add 3.5 g (0.02 mol) of toluene diisocyanate after the temperature of the solution in the reaction vessel reaches 50° C. Then add the catalyst stannous octoate (the amount accounts for 3% of the total mass of the reaction system), keep the temperature for 1 hour after adding, then raise the temperature to 70° C., and keep the temperature for 4 hours. Add 1.04g of sodium bisulfite, strengthen the stirring, continue to stir for 1h, add water into the reaction kettle, and stir for 30min to obtain a retarder for refractory materials, named as HN-2.

Embodiment 3

[0023] Weigh 20g (0.01mol) of polybutylene adipate (molecular weight 2000), 20mL of N-methylpyrrolidone, 2.54g (0.005mol) of methylsilsesquioxane, add the in the flask. Stir at a constant speed with a stirrer, and heat up to 50°C; after the temperature of the solution in the reaction vessel reaches 50°C, add 3.4g (0.02mol) of hexamethylene diisocyanate. Then add the catalyst stannous oleate (the amount accounts for 4% of the total mass of the reaction system), keep the temperature for 1 hour after adding, then raise the temperature to 70° C., and keep the temperature for 4 hours. Add 1.04g of sodium bisulfite, strengthen the stirring, continue to stir for 1h, add water into the reaction kettle, and stir for 30min to obtain a retarder for refractory materials, named as HN-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com