Polyester drawn textured yarn and preparation method thereof

A technology of polyester high elastic yarn and polyester, which is applied in rayon manufacturing, filament/thread forming, conjugated synthetic polymer rayon, etc. It can solve the problems of crimping, low breaking strength and high shrinkage, etc. Achieve the effects of reduced shrinkage, high breaking strength, and large curl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of polyester stretch yarn, comprising the steps of:

[0024] Put the polyester raw material into the mixer for mixing, and after mixing evenly, put it into the hot-melt spinning machine for spinning, then cool, oil and wind to obtain polyester pre-oriented filaments, which are spun into polyester pre-oriented filaments Silk (POY), the POY specification is 289-291dtex / 48f, the breaking strength is 2.1-2.3cN / dtex, the breaking elongation is 130-140%, and the oil content is 0.3-0.4%;

[0025] The above-mentioned polyester pre-oriented filaments are texturized on a texturing machine, and the polyester pre-oriented filaments are pulled by one roller, and fed into the first hot box with a temperature of 180-220°C for heating, and then the heated polyester pre-oriented filaments are heated. False-twist the oriented filaments, and then carry out two rollers on the false-twisted raw yarns, and feed them into the second hot box with a temperature of 20-30°C, ...

Embodiment 1-11

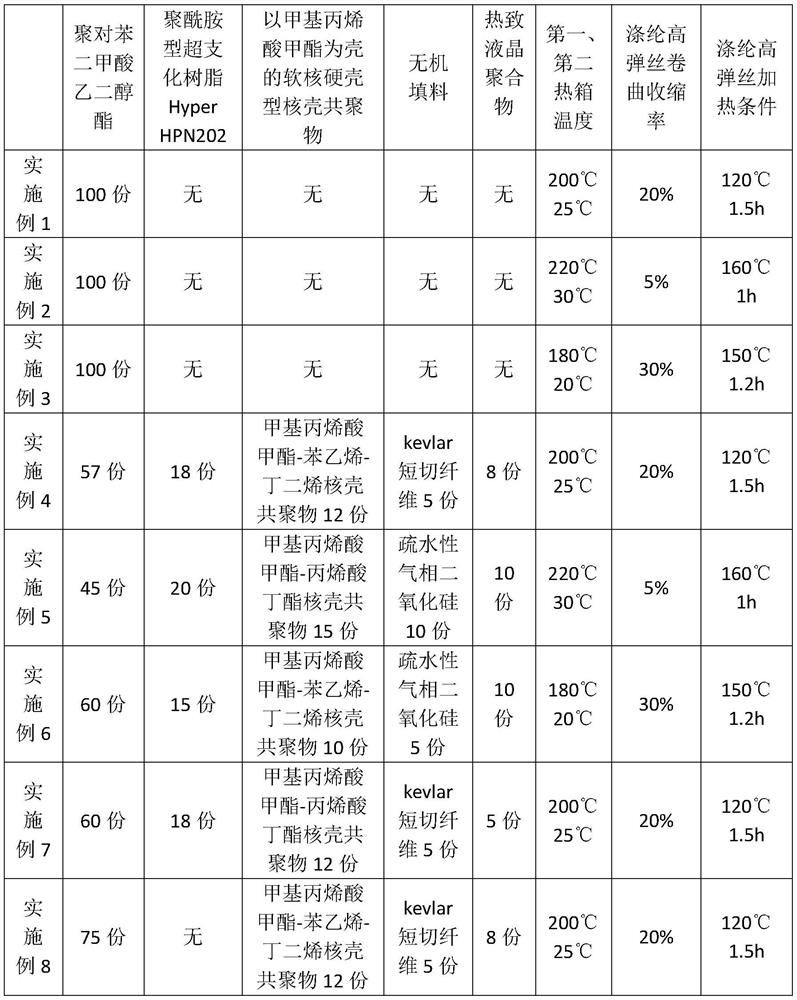

[0029] Table 1 Components and process conditions used in the preparation of polyester elastic yarn

[0030]

[0031]

[0032] Note: Examples 1-5 all used 8 parts of hindered phenolic antioxidant antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate.

[0033] Effect example

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com