Preparation process of high-formability 6111 aluminum alloy automobile plate

A preparation process and technology of aluminum alloy plate, which is applied in the field of metal materials, can solve the problems such as poor stamping and forming effect of 6111 aluminum alloy automobile plate, and achieve the effect of speeding up the lightweight process, good formability, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

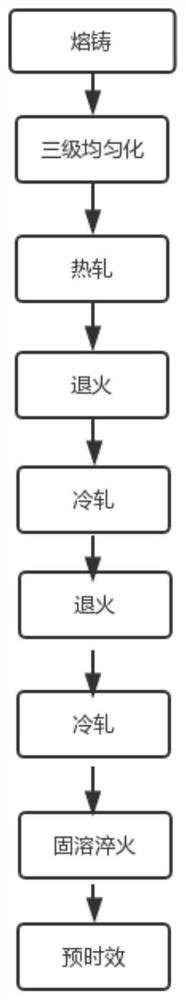

[0026] Such as figure 1 A preparation process for a high formability 6111 aluminum alloy automobile sheet is shown, comprising the following steps:

[0027] A. Ingredients: The aluminum alloy raw materials for the preparation of aluminum alloy plates are mixed according to weight percentage, namely: Si: 0.5-1.0%, Fe: 0.1-0.4%, Cu: 0.6-0.8%, Mn: 0.2-0.4%, Mg : 0.6~0.8%, Cr: 0.10%, Zn: 0.10%, single impurity ≤0.05%, total ≤0.15%, the balance is Al;

[0028] B. Melting and casting: Put the configured aluminum alloy raw materials into the melting furnace in turn for melting. The aluminum alloy raw materials are industrial pure aluminum, industrial pure Mg, industrial pure Zn, master alloy Al-Si, master alloy Al-Cu, master alloy Al -Fe, intermediate alloy Al-Mn, etc., and use flux to refine and cover. After feeding, start stirring when aluminum water appears in the furnace. After stirring evenly, it will be melted into liquid aluminum alloy. The melting temperature is 700-760 ° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com