A swirl exhaust device and system

An exhaust device and swirling technology, applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, can solve the problems of pollutants escaping, insufficient suction distance, and poor collection effect of exhaust pipes. Achieve the effect of efficiently capturing pollutants, increasing the range of action, and avoiding the escape of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides two design trapping strategies and exhaust modes, which are mode a and mode b respectively.

[0060] In mode a, for the working condition where the pollutants are greatly affected by the ambient wind, the rotation of the blades of the exhaust outlet of the exhaust pipe 1 generates a high radial velocity to effectively shield the ambient wind such as the side airflow, so that the pollutants are discharged from the air. The negative pressure area of the air duct 1 is inhaled.

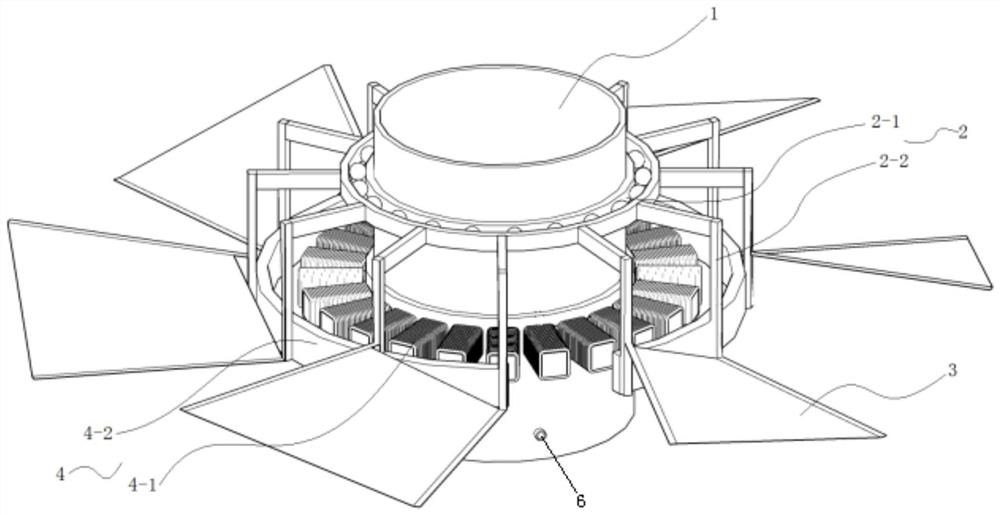

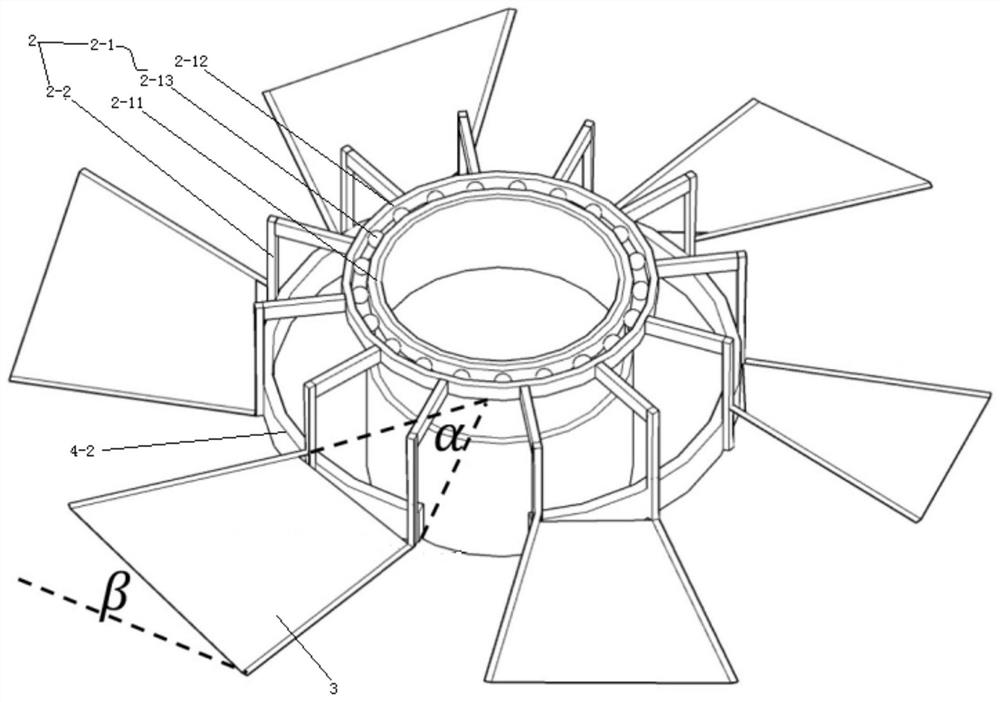

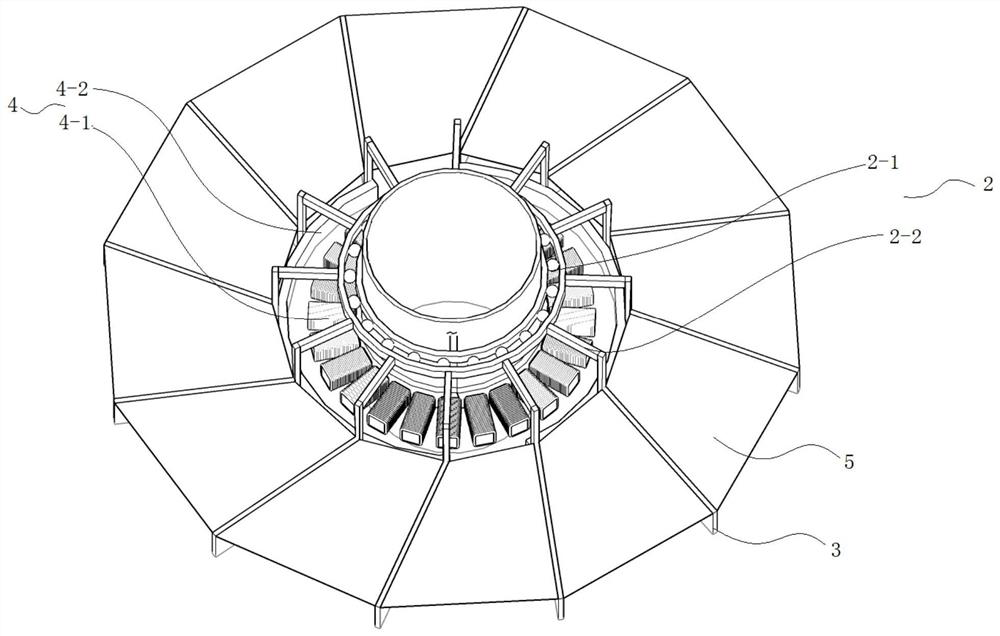

[0061] In order to realize above-mentioned technical task, the present invention is realized like this, as Figure 1-Figure 2 Shown:

[0062] The exhaust pipe 1 is located in the middle position, and the support ring assembly 2-1 (bearing) is welded on the periphery of the exhaust pipe 1, and the other side of the support ring assembly 2-1 (bearing) is glued to the blade through the connecting arm 2-2. The blades are made of plastic to ensure light structure, and the an...

Embodiment 2

[0067] This embodiment provides experimental verification for mode a and mode b, and compares the capture effect of commonly used traditional umbrella covers. The experimental results show that the present invention can effectively capture pollutants emitted in the environment. In this embodiment, CFD numerical simulation is used to carry out numerical experiments of fluid mechanics. This embodiment adopts the component transport model (Species transport). The component transport model can analyze the flow process of gas flow between different gas components in detail.

[0068] In this embodiment, the test environment is a small volatile workshop whose size is 2m long*2m wide*2m high. There is a high-temperature organic volatilization barrel 7 in the center of the room, and the diameter of the barrel is 0.2m; in addition, at a position of 1.8m in height, it is the position of the exhaust pipe 1, and the diameter of the two hoods is 0.4m, wherein the blade rotation diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com