A kind of lithium ion battery negative electrode slurry and its preparation method and lithium ion battery

A lithium-ion battery and negative electrode slurry technology, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve problems that do not involve improving the wettability of powder materials, and achieve enhanced ion/electron transmission capabilities, increased energy density, The effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

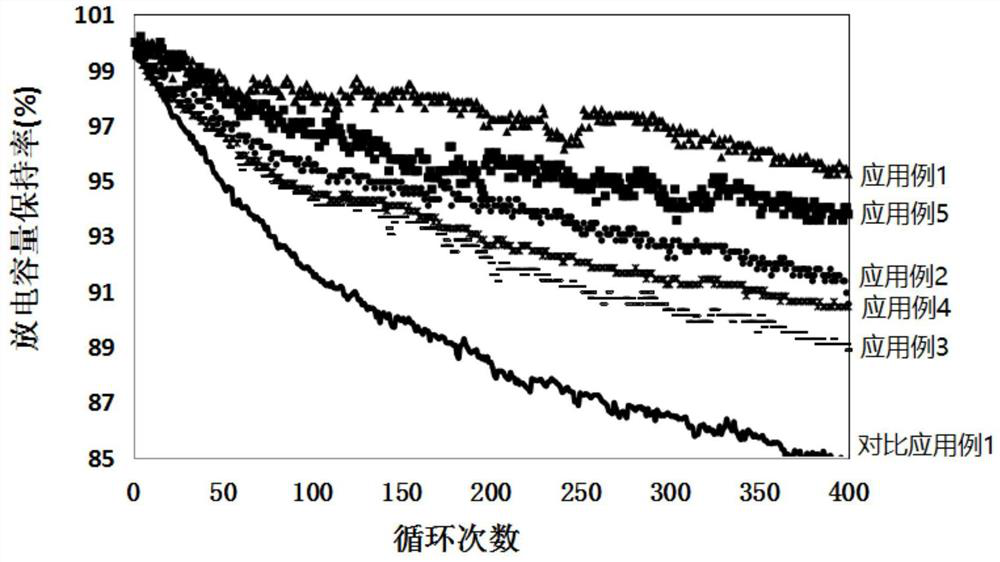

Examples

Embodiment 1

[0068] This embodiment provides a figure 1 The preparation method of the negative electrode slurry of lithium ion battery shown, described preparation method comprises the following steps:

[0069] (1) Mix negative electrode active powder material KS-6 artificial graphite and conductive agent powder material T300 carbon fiber, obtain the first powder material after degassing treatment; described degassing treatment is to carry out heating and vacuumizing simultaneously, and the temperature of heating is 150 ℃ , the absolute vacuum degree of vacuuming is 0.005Pa; the time of degassing treatment is 20min;

[0070] (2) Pass the humidity-promoting gas carbon dioxide with a gauge pressure of 0.5 MPa into the first powder, and obtain the second powder after adsorption saturation;

[0071] (3) Stir at a rate of 300 rpm for 15 minutes to mix the second powder and deionized water, and obtain an intermediate slurry after degassing treatment; the degassing treatment is carried out at th...

Embodiment 2

[0076] This embodiment provides a figure 1 The preparation method of the negative electrode slurry of lithium ion battery shown, described preparation method comprises the following steps:

[0077] (1) Mix negative electrode active powder material KS-15 artificial graphite and conductive agent powder material T700 carbon fiber, obtain the first powder material after degassing treatment; described degassing treatment is to carry out heating and vacuumizing simultaneously, and the temperature of heating is 125 ℃ , the absolute vacuum degree of vacuuming is 0.003Pa; the time of degassing treatment is 15min;

[0078] (2) The moisture-promoting gas ammonia whose gauge pressure is 0.25 MPa is passed into the first powder, and the second powder is obtained after adsorption saturation;

[0079] (3) Stirring at a rate of 200rpm for 12.5min to mix the second powder and deionized water, and obtain an intermediate slurry after degassing; The absolute vacuum degree of vacuum is 0.025Pa; ...

Embodiment 3

[0084] This embodiment provides a figure 1 The preparation method of the negative electrode slurry of lithium ion battery shown, described preparation method comprises the following steps:

[0085] (1) Mix negative electrode active powder material SFG-6 artificial graphite and conductive agent powder material M30 carbon fiber, obtain the first powder material after degassing treatment; described degassing treatment is to carry out heating and vacuumizing simultaneously, and the temperature of heating is 175 ℃ , the absolute vacuum degree of vacuuming is 0.008Pa; the time of degassing treatment is 25min;

[0086] (2) passing the moisture-promoting gas chlorine gas with a gauge pressure of 0.75MPa into the first powder, and obtaining the second powder after adsorption saturation;

[0087] (3) Stirring at a rate of 400rpm for 17.5min to mix the second powder and deionized water, and obtain an intermediate slurry after degassing; The absolute vacuum degree of vacuum is 0.075Pa; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com