Floor waterproof material manufacturing method

A technology of waterproof material and production method, which is applied in fireproof coatings, wax coatings, polyurea/polyurethane coatings, etc., which can solve the problems of troublesome construction methods, affecting the construction period, poor wear resistance of waterproof membranes, etc., and achieve convenient and fast construction and waterproof effect Remarkable, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

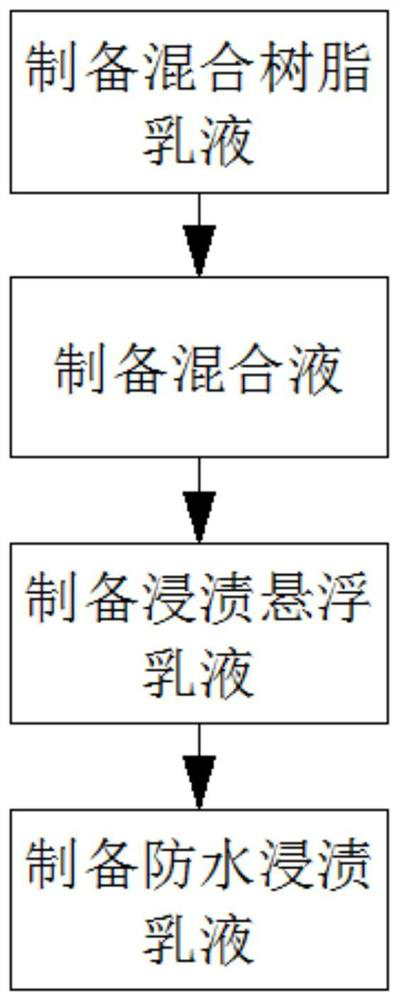

[0021] according to figure 1 As shown, the present embodiment provides a method for making a floor waterproof material, comprising the following steps:

[0022] Step 1. Batching water-soluble phenolic resin and water-based polyurethane resin emulsion according to the required amount, adding them to the reactor for mixing and stirring at a stirring rate of 120-140 rpm to prepare a mixed resin emulsion;

[0023] Step 2. Mix hydrophobic silicon dioxide, talcum powder, flame retardant, nano-magnesia and aluminum oxide according to the required proportions to obtain a mixed powder, and then add the mixed powder to the mixed resin emulsion prepared in step 1. , use the reactor to continue mixing and stirring, the stirring rate is reduced to 80-100 rpm, and the mixed solution is obtained;

[0024] Step 3, batching sodium pyrophosphate and melamine according to the required amount, and then adding to the mixed solution prepared in step 2 to mix and stir, and the stirring speed is rai...

Embodiment 2

[0032] according to figure 1 As shown, the present embodiment provides a method for making a floor waterproof material, comprising the following steps:

[0033] Step 1. Batching water-soluble phenolic resin and water-based polyurethane resin emulsion according to the required amount, adding them to the reactor for mixing and stirring at a stirring rate of 120-140 rpm to prepare a mixed resin emulsion;

[0034] Step 2. Mix hydrophobic silicon dioxide, talcum powder, flame retardant, nano-magnesia and aluminum oxide according to the required proportions to obtain a mixed powder, and then add the mixed powder to the mixed resin emulsion prepared in step 1. , use the reactor to continue mixing and stirring, the stirring rate is reduced to 80-100 rpm, and the mixed solution is obtained;

[0035] Step 3, batching sodium pyrophosphate and melamine according to the required amount, and then adding to the mixed solution prepared in step 2 to mix and stir, and the stirring speed is rai...

Embodiment 3

[0043] according to figure 1 As shown, the present embodiment provides a method for making a floor waterproof material, comprising the following steps:

[0044] Step 1. Batching water-soluble phenolic resin and water-based polyurethane resin emulsion according to the required amount, adding them to the reactor for mixing and stirring at a stirring rate of 120-140 rpm to prepare a mixed resin emulsion;

[0045] Step 2. Mix hydrophobic silicon dioxide, talcum powder, flame retardant, nano-magnesia and aluminum oxide according to the required proportions to obtain a mixed powder, and then add the mixed powder to the mixed resin emulsion prepared in step 1. , use the reactor to continue mixing and stirring, the stirring rate is reduced to 80-100 rpm, and the mixed solution is obtained;

[0046] Step 3, batching sodium pyrophosphate and melamine according to the required amount, and then adding to the mixed solution prepared in step 2 to mix and stir, and the stirring speed is raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com