Water-permeable asphalt concrete as well as preparation method and application thereof

A permeable asphalt and concrete technology, applied in the field of materials, can solve the problems of reduced water permeability coefficient and limited strength of permeable concrete, etc., and achieve the effects of excellent crack resistance, good structural strength and water permeability, high water permeability and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

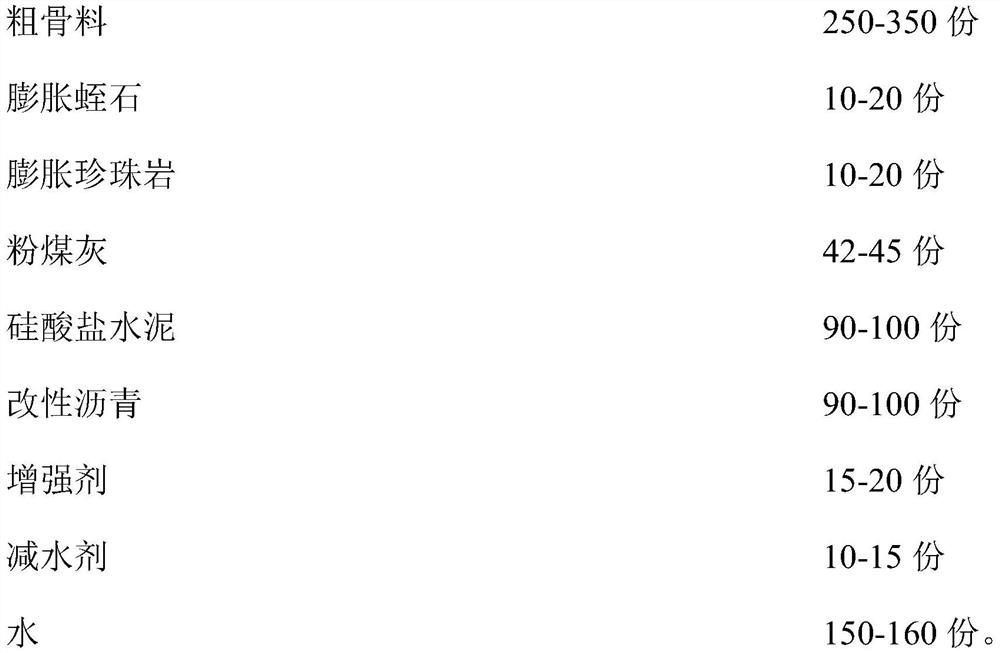

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a kind of preparation method of permeable asphalt concrete, and described preparation method comprises the following steps:

[0062] (1) Uniformly mix coarse aggregate, fine aggregate, fly ash, modified asphalt and 50% of water according to the formula to obtain mixed slurry a;

[0063] (2) Uniformly mix ordinary portland cement 42.5, reinforcing agent, water reducer and remaining water according to the formula to obtain mixed slurry b;

[0064] (3) Uniformly mixing the mixed slurry a obtained in step (1) with the mixed slurry b obtained in step (2) under stirring conditions to obtain the permeable asphalt concrete.

[0065] The stirring in step (3) is first stirring at 400r / min for 20min, and then uniformly at 80r / min for 45min.

[0066] In terms of parts by weight, the raw materials of permeable asphalt concrete include: 300 parts of 5-25mm continuous grade gravel, 15 parts of expanded vermiculite, 15 parts of expanded perlite, 43 parts of fl...

Embodiment 2

[0070] This embodiment provides a kind of preparation method of permeable asphalt concrete, and described preparation method comprises the following steps:

[0071] (1) Uniformly mix coarse aggregate, fine aggregate, fly ash, modified asphalt and 50% of water according to the formula to obtain mixed slurry a;

[0072] (2) Uniformly mix ordinary portland cement 42.5, reinforcing agent, water reducer and remaining water according to the formula to obtain mixed slurry b;

[0073] (3) Uniformly mixing the mixed slurry a obtained in step (1) with the mixed slurry b obtained in step (2) under stirring conditions to obtain the permeable asphalt concrete.

[0074] The stirring in step (3) is first stirring at 350r / min for 25min, and then stirring at 60r / min for 50min.

[0075] In terms of parts by weight, the raw materials of permeable asphalt concrete include: 280 parts of 5-25mm continuous grade crushed stone, 12 parts of expanded vermiculite, 18 parts of expanded perlite, 44 parts...

Embodiment 3

[0079] This embodiment provides a kind of preparation method of permeable asphalt concrete, and described preparation method comprises the following steps:

[0080] (1) Uniformly mix coarse aggregate, fine aggregate, fly ash, modified asphalt and 50% of water according to the formula to obtain mixed slurry a;

[0081] (2) Uniformly mix ordinary portland cement 42.5, reinforcing agent, water reducer and remaining water according to the formula to obtain mixed slurry b;

[0082] (3) Uniformly mixing the mixed slurry a obtained in step (1) with the mixed slurry b obtained in step (2) under stirring conditions to obtain the permeable asphalt concrete.

[0083]The stirring in step (3) is first stirring at 300r / min for 30min, and then stirring at 50r / min for 60min.

[0084] In terms of parts by weight, the raw materials of permeable asphalt concrete include: 250 parts of 5-25mm continuous grade crushed stone, 10 parts of expanded vermiculite, 20 parts of expanded perlite, 45 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com