Micro-surfacing mixing material with performances of high abrasion resistance and water damage resistance

A micro-surfacing mixture and anti-water damage technology, which is applied in the field of pavement maintenance, can solve the problems of short service life of the micro-surfacing pavement, achieve the effects of reducing particle drop, improving water damage resistance, and enhancing bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with embodiment and accompanying drawing.

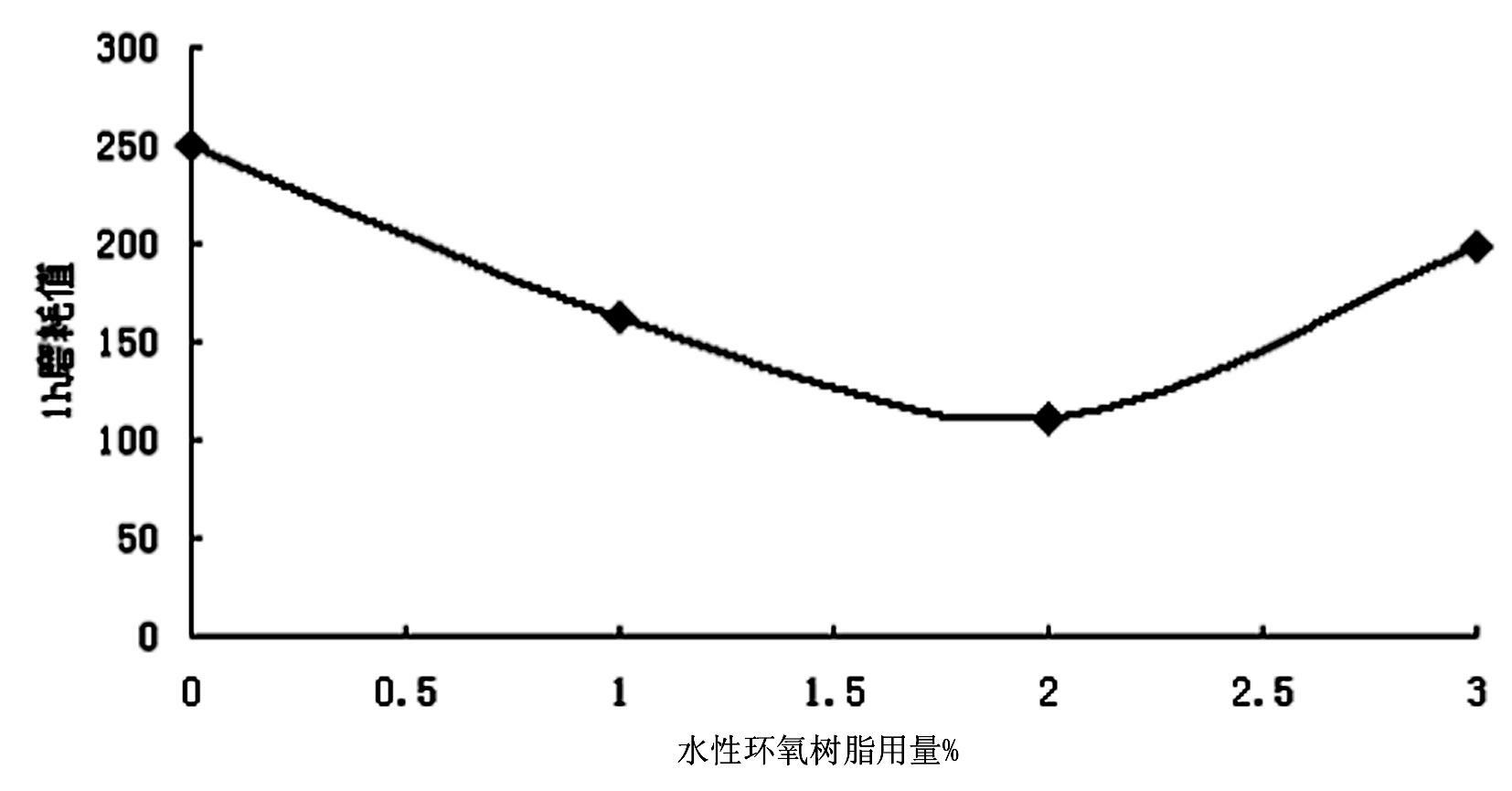

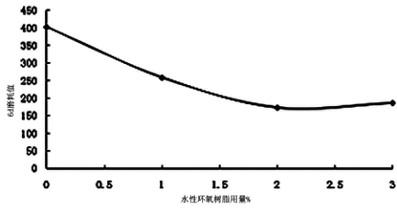

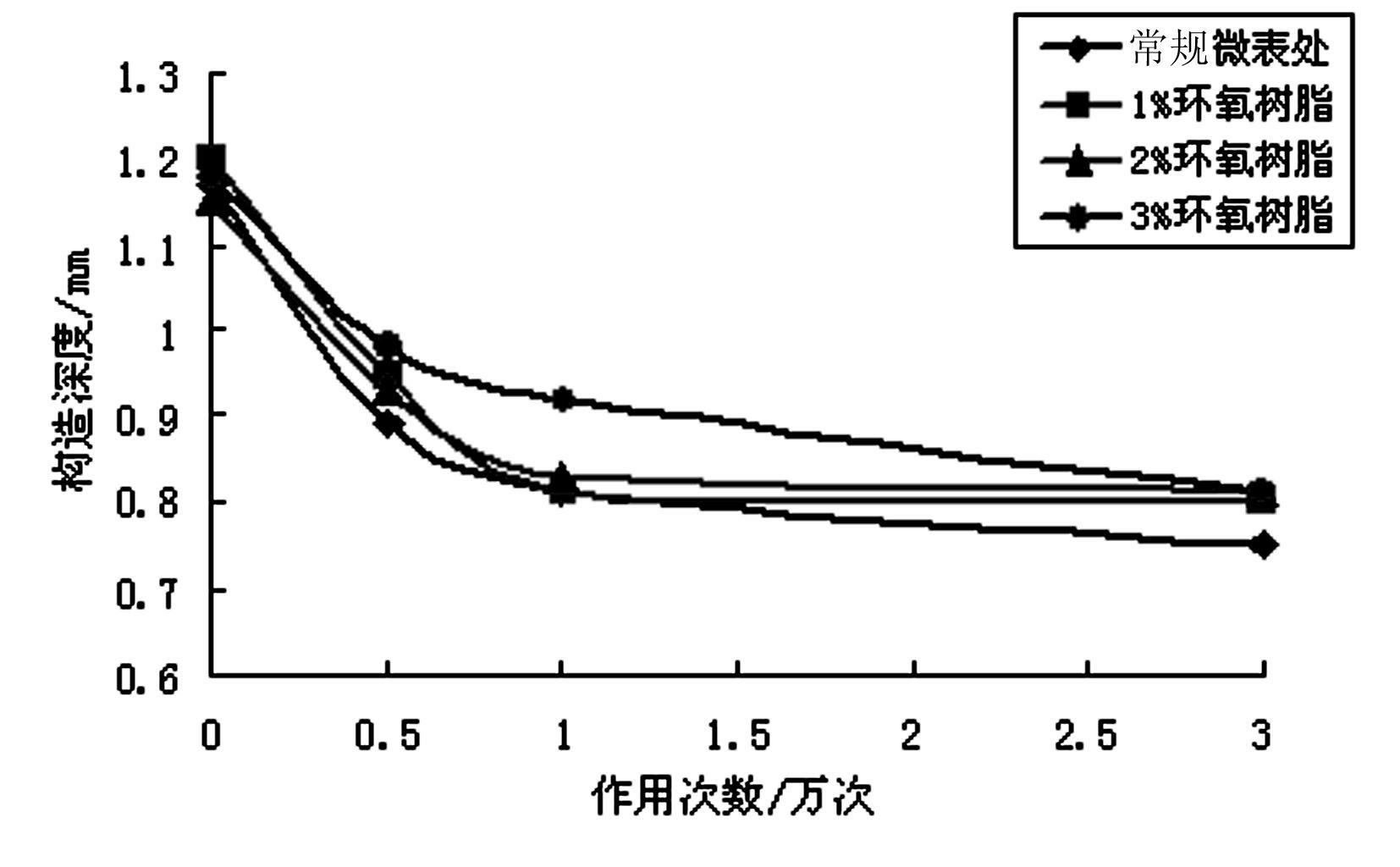

[0019] The formula of the micro-surface mixture: by weight, 100 parts of aggregate, 10-13 parts of modified emulsified asphalt, 0.10-0.39 parts of water-based epoxy resin, 0.15-0.59 parts of water-based epoxy curing agent, 1-3 parts of cement 7 to 9 parts with water.

[0020] A more optimal formula is: by weight, 100 parts of aggregate, 10-13 parts of modified emulsified asphalt, 0.10-0.26 parts of water-based epoxy resin, 0.15-0.39 parts of water-based epoxy curing agent, 1-3 parts of cement and water 7 to 9 servings.

[0021] The water-based epoxy resin and water-based epoxy curing agent used in this experiment have the following technical indicators

[0022] Using products with the above technical indicators, when the weight ratio of water-based epoxy resin to water-based epoxy curing agent reaches 1:1.5, the curing effect is the best and the best bonding p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com