Flushing device with porous rotary jet structure

A technology of flushing device and jet, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insufficient water power, no mention, damage, etc. Loss, increased speed and pressure, effect of increased cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

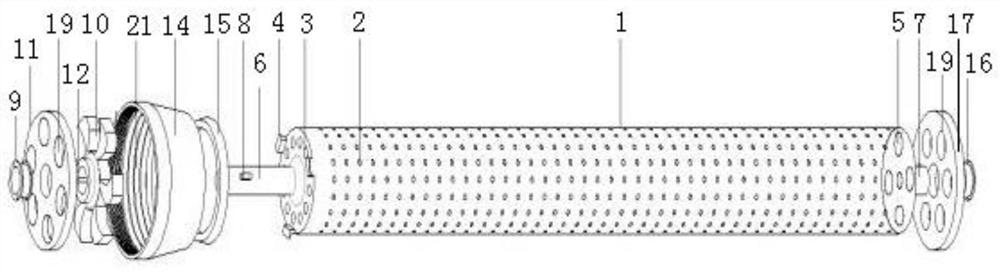

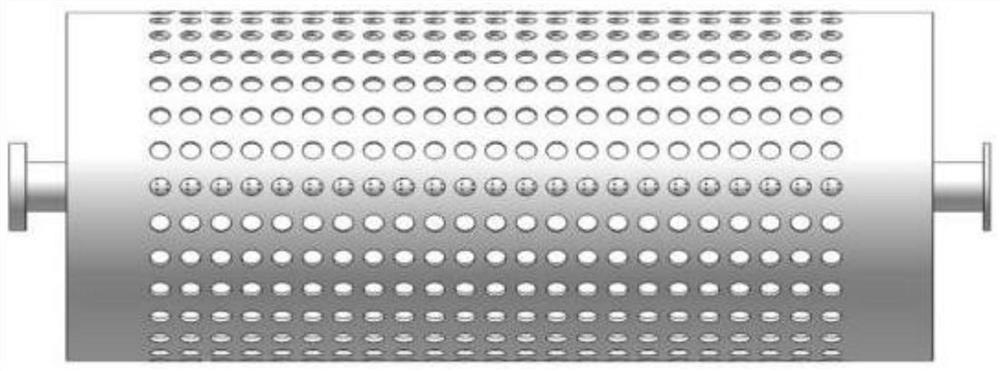

[0020]The main structure of the flushing device with a porous rotating jet structure involved in this embodiment includes a rotating water jet shaft barrel 1, a water jet hole 2, a water inlet hole 3, a buckle 4, a water outlet hole 5, a front shaft 6, a rear shaft 7, and a spline 8 , No. 1 bearing bush 9, turbofan 10, front splitter 11, keyway 12, front flange 13, drainage pipe 14, sealing ring 15, No. 2 bearing bush 16, rear splitter 17, rear flange 18 , diversion holes 19 and positioning protrusions 20; the outer circumference of the hollow cylindrical structure of the rotary water jet shaft tube 1 is uniformly provided with several circular water jet holes 2, and the left end surface of the rotary water jet shaft tube 1 Several water inlet holes 3 of circular structure and buckles 4 of wedge-shaped structure are arranged at equal intervals, and several water outlet holes 5 of circular structure are arranged at equal intervals on the right end surface of the rotating water j...

Embodiment 2

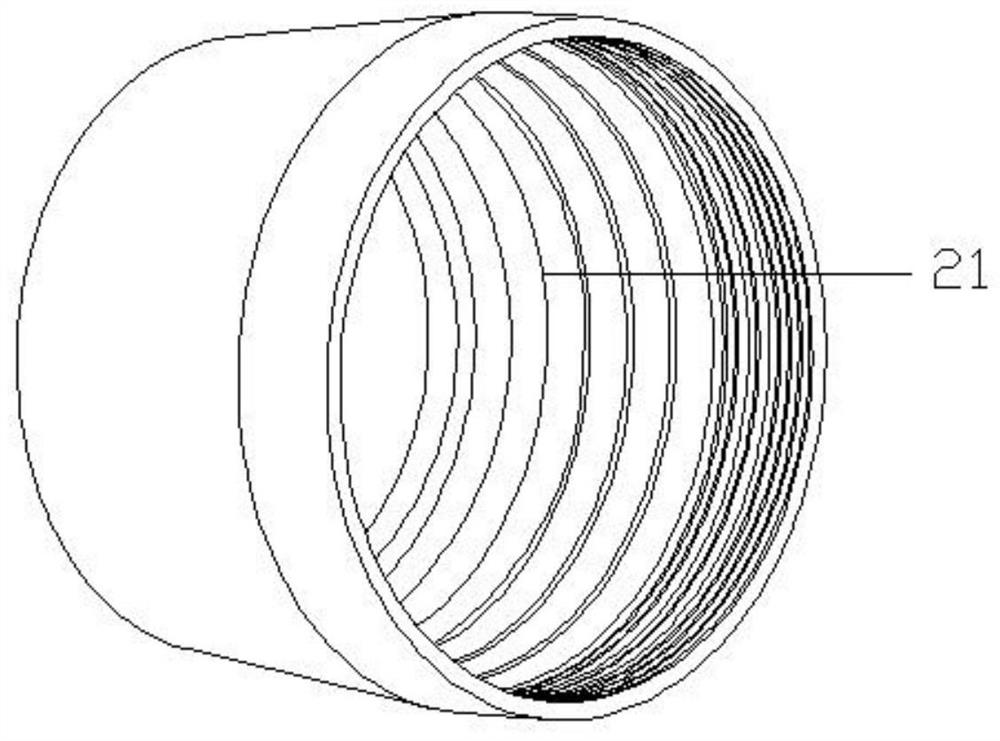

[0022] When the flushing device with porous rotating jet structure involved in this embodiment is prepared and used, the front flange 13 and the rear flange 18 are respectively connected with the water-absorbing sleeve 100 bolted on the lotus root harvester, and the water flows from the front The blue plate 13 enters, passes through the split hole 19 of the front splitter 11, and acts vertically on the blade of the turbofan 10. Since the front splitter 11 is fastened in the front flange 13, the front splitter 11 is affected by the impact of the water flow. The bottom will not move to the right, the turbofan 10 rotates under the impact of the water flow, and at the same time drives the rotating water jet shaft barrel 1 to rotate; The bionic earthworm body surface pattern 21 on the inner wall can reduce the pressure loss along the water flow. The buckle 4 of the wedge structure and the sealing ring 15 of the ring structure work together to ensure the sealing of the waterway and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com