Tail gas absorption process and device in melamine production process

A melamine and production process technology, applied in the field of tail gas absorption technology and devices, can solve the problems of low absorption efficiency, low ammonia concentration, waste and the like, and achieve the effects of convenient operation, high economic benefit and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

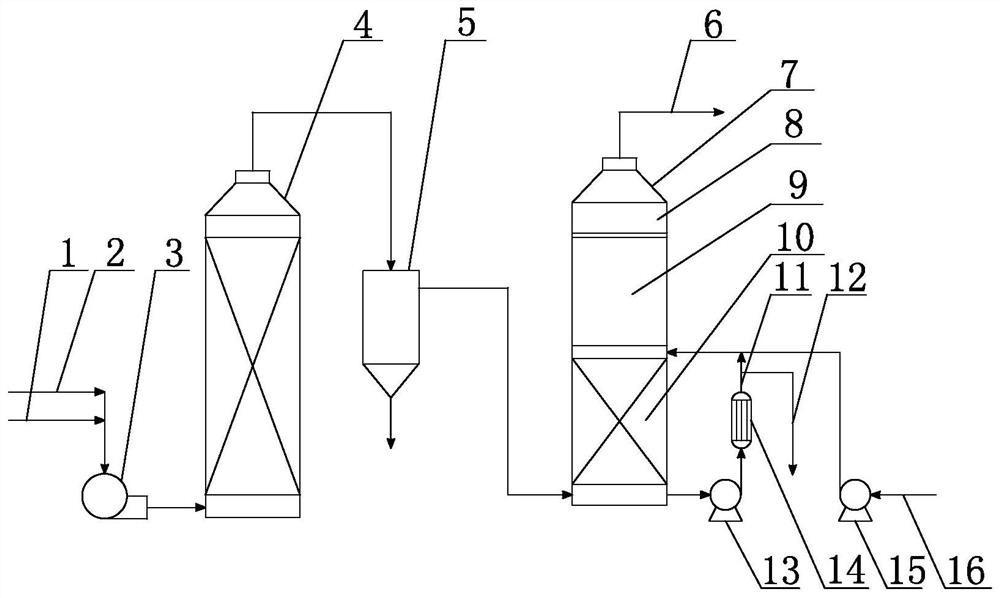

[0025] Such as figure 1 Shown, the used device of the tail gas absorption process in the melamine production process of the present invention comprises Roots fan 3, water absorption tower 4, cyclone separator 5 and acid absorption tower 7 connected successively; Acid absorption tower 7 consists of the following A packing section 10, a bubble cap section 9 and a mist eliminator 8 are set up in sequence; the air inlet at the lower end of the packing section 10 of the acid absorption tower 7 is connected with the gas outlet of the cyclone separator 5, and the liquid inlet at the upper end is connected with the acid absorption liquid pipeline 16 are connected; the top of the acid absorption tower 7 is connected with a tail gas discharge pipeline 6.

[0026] The Roots blower 3 is connected with the melamine packaging tail gas pipeline 1 and the urea melting tail gas pipeline 2 .

[0027] The liquid outlet at the lower end of the packing section 10 of the acid absorption tower 7 is...

Embodiment 2

[0031] Adopt the tail gas absorption device of embodiment 1 to absorb the tail gas in the melamine production process of our company, the tail gas absolute pressure is 101.3KPa, the ammonia gas content is 2-4%, and contains trace melamine and urea, the steps are as follows:

[0032] (1) Water absorption: After the exhaust gas is boosted by the Roots blower, enter the water absorption tower, use water to absorb ammonia, urea and melamine in the tail gas, control the ammonia concentration of the water absorption tower between 6-8wt%, and then enter the cyclone separator for separation;

[0033] (2) Acid absorption: the tail gas after separation enters the packing section of the acid absorption tower, and the ammonia in the tail gas is further absorbed with 5wt% nitric acid, and the acid absorption liquid is recycled through a circulating pump to control the pH value of the acid absorption liquid When the pH value of the acid absorption liquid is greater than 5, the acid absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com