Self-separation concrete vibrating bar adopting cold type water drainage technology

A technology of concrete and vibrating rods, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of reducing the service life of vibrating rods and poor results, and achieve the effect of improving reaction efficiency and cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

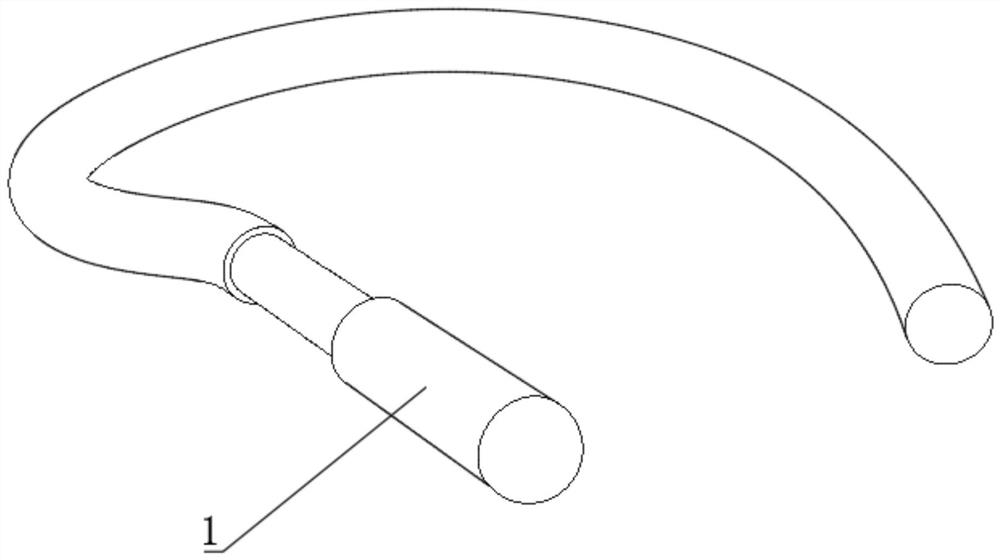

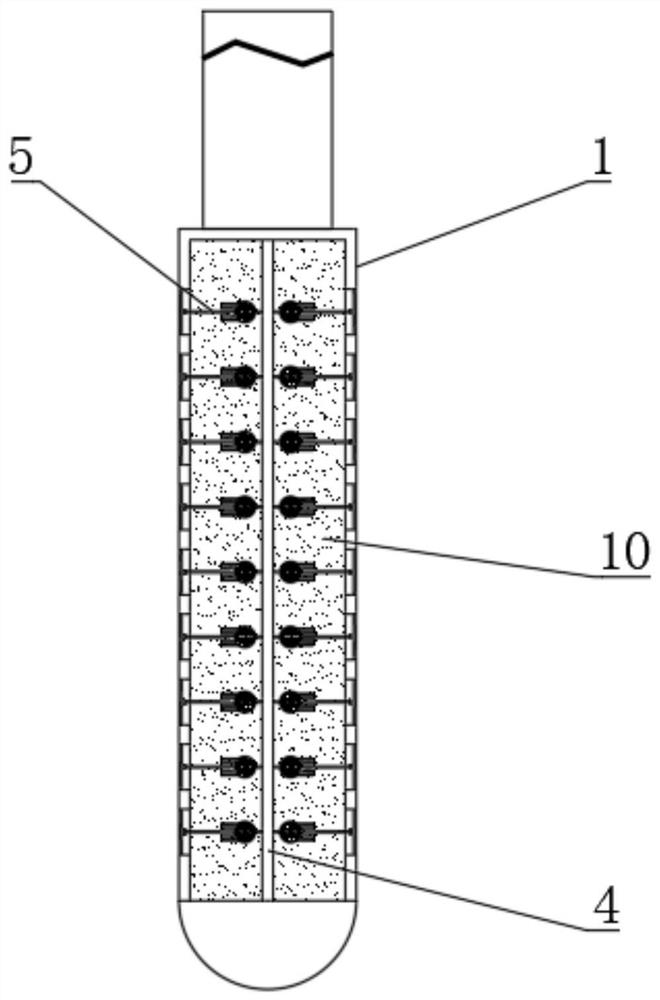

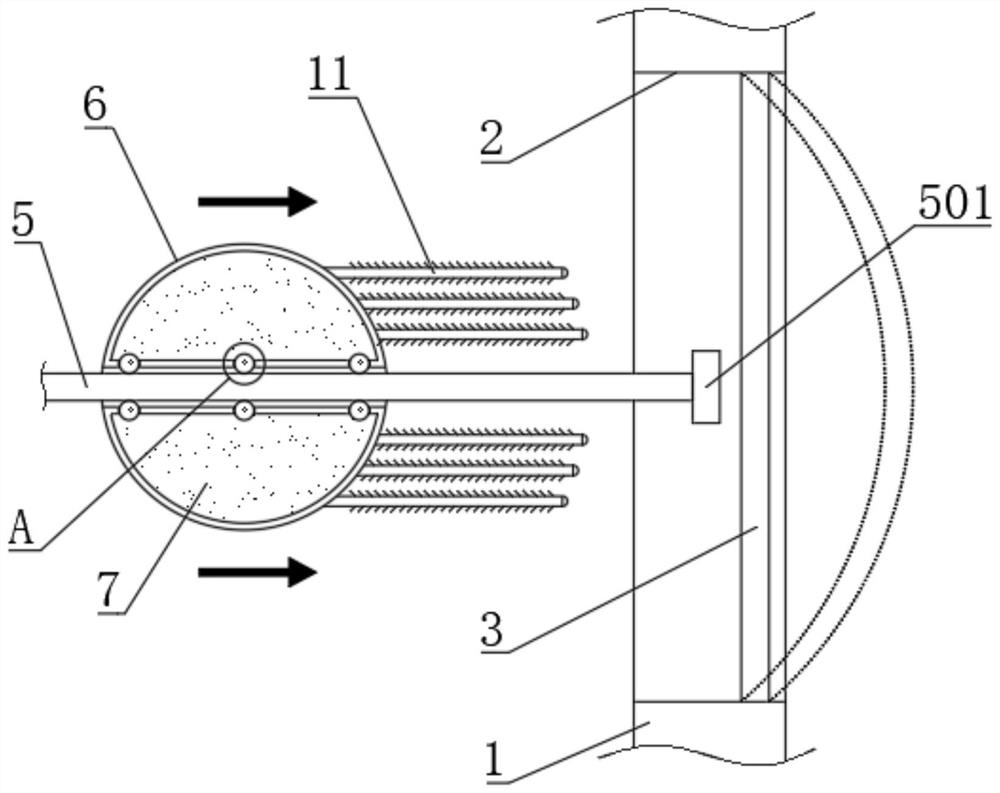

[0040] see Figure 1-4 , a self-detachable concrete vibrator with cold hydrophobic technology, including a vibrating end 1, the outer end of the vibrating end 1 is dug with a plurality of evenly distributed exchange through holes 2, and the inner wall of the exchange through hole 2 is connected with an elastic sealing film 3. A central main rod 4 is connected between the upper and lower inner walls of the vibrating end 1, and the outer end of the central main rod 4 is threadedly connected with a plurality of evenly distributed side sub-rods 5, and the outer end of the side sub-rod 5 is slidingly connected with Release the ball frame 6, the release ball frame 6 is filled with octahydrate barium hydroxide powder 7, the inner wall of the release ball frame 6 is dug with a plurality of evenly distributed release round holes 8, and the inner wall of the release round hole 8 is rotatably connected with a movable ball 9, The vibrating head 1 is filled with ammonium chloride powder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com