Preparation process, using method and application of non-zero-degree phase change point self-water-injection ice bag

A technology of preparation process and phase transition point, applied in the fields of application, chemical instruments and methods, and preservation of meat/fish with solids, etc., can solve problems such as difficulty in promotion and use, poor mixing effect, etc., achieve gentle temperature curve, improve usability Precise effect of time and temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

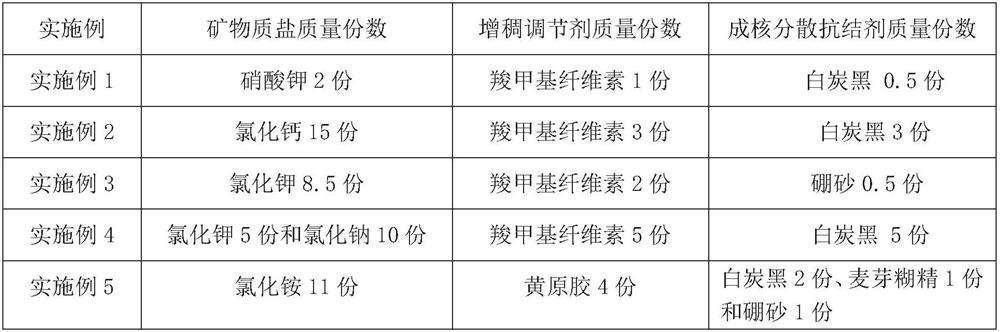

[0027] S1: mix the mineral salt and the thickening regulator according to the distribution ratio of the parts by weight in Table 1 to obtain the mixture (A);

[0028] S2: adding the nucleating dispersing anti-caking agent to the above mixture (A), stirring at a high speed to make it fully mixed to obtain the content (B);

[0029] S3: Pack the above content (B) to obtain a non-zero phase transition point self-filling ice bag (C).

[0030] Table 1

[0031]

[0032] Embodiment 1-4 of the method of use:

[0033] S1: Add water to the non-zero phase transition point self-filling water ice bag (C) prepared in the above preparation process example 1-4 according to the proportions in Table 2;

[0034] S2: After shaking well or standing still for 5-20 minutes, put it into the freezer for 10-24 hours and freeze it for 10-24 hours. After taking it out, put it in an insulated container together with the items that need to be refrigerated.

[0035] Table 2

[0036] Example o...

experiment example 1

[0037] Experimental Example 1: Application of water-filled ice packs of the present invention in keeping beef fresh

[0038] Experimental material: frozen beef

[0039] Experimental treatment: 250g of frozen beef is packed in a packaging bag, and then placed in a foam box together with 1000g of self-injected water ice packs with a phase change point of -22.3° of Example 4 that has been injected with water and frozen. The control group is 1000g of zero-degree phase change ice packs , and the rest of the conditions are the same. The foam box containing the beef was placed at room temperature for 3 days. After three days, the beef deterioration rate of the experimental group was 11.3%, and the beef deterioration rate of the control group was 33.5%.

[0040] The invention provides a simple, cheap, non-toxic, non-zero-degree ice pack preparation process, which can be filled with water when used, shaken well or put into a freezer to freeze before use, which solves the problem of hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com