Preparation method and application of coating containing compound plant extracted essential oil

A technology for extracting essential oils and coatings from plants, applied in the field of coatings, can solve problems such as poor human sensory effects, affecting air quality, pungent sensation, etc., and achieve the effects of prolonging health care effects, improving indoor air, and anti-anxiety sleep.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

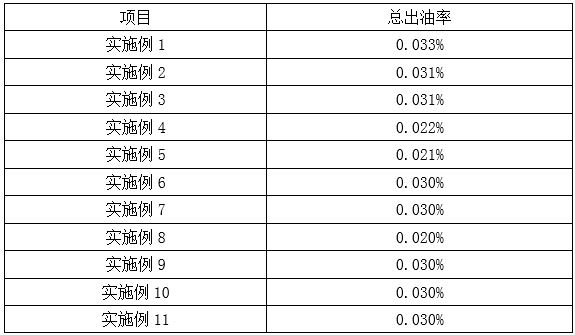

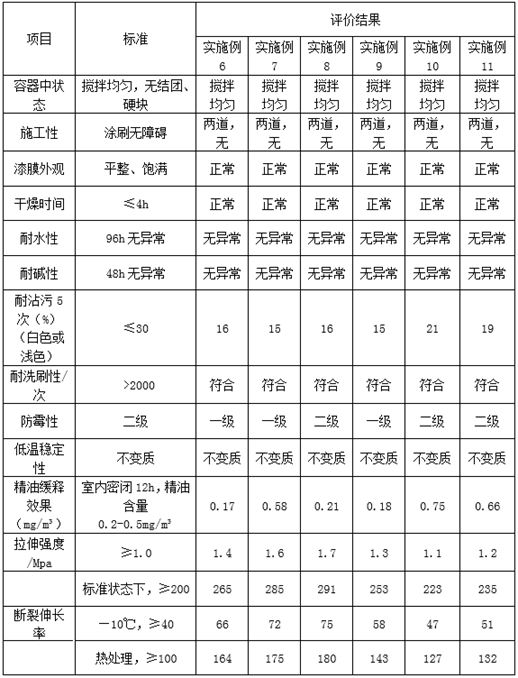

Examples

Embodiment 1

[0032] A preparation method and application of a paint containing compound plant extract essential oil, wherein the extraction of compound plant extract essential oil comprises the following steps of preparation:

[0033](1) Divide the raw materials into groups a, b, and c. Group a includes 2000 parts of zong leaves, 1600 parts of camphor leaves, and 1500 parts of tea leaves. Group b includes 1500 parts of mint and 1800 parts of roses. Group c includes lemon peel 2500 parts and 2300 parts of orange peel; the three groups of raw materials were washed with water, and then soaked in an aqueous solution containing 2.0% sodium chloride mass fraction and 2.5% ethanol mass fraction for 6 hours, and ultrasonic treatment with a frequency of 22KHz , take it out and rinse it with pure water for 3-5 times, put it into a drier and dry it at a low temperature of 35°C until the water content is 8%, then put it into an ultrafine pulverizer and grind it to 80um to obtain composite plant powders...

Embodiment 2

[0049] A preparation method and application of a paint containing compound plant extract essential oil, wherein the extraction of compound plant extract essential oil comprises the following steps of preparation:

[0050] (1) Divide the raw materials into groups a, b, and c. Group a includes 1,500 parts of zong leaves, 2,000 parts of camphor leaves, and 1,300 parts of tea tree leaves. Group b includes 2,000 parts of mint and 1,500 parts of roses. Group c includes lemon peel 3000 parts and 1800 parts of orange peel; the three groups of raw materials were washed with water, and then soaked in an aqueous solution containing 2.5% sodium chloride mass fraction and 2.2% ethanol mass fraction for 8 hours, and ultrasonic treatment with a frequency of 20KHz , take it out and rinse it with pure water for 5 times, put it into a drier and dry it at a low temperature of 30°C until the water content is 10%, then put it into an ultrafine pulverizer and pulverize it to 50um to obtain composite...

Embodiment 3

[0065] A preparation method and application of a paint containing compound plant extract essential oil, wherein the extraction of compound plant extract essential oil comprises the following steps of preparation:

[0066] (1) Divide the raw materials into three groups a, b, and c. Group a includes 2500 parts of zong leaves, 1200 parts of camphor leaves, and 1800 parts of tea tree leaves. Group b includes 1000 parts of mint and 2000 parts of roses. Group c includes lemon peel 2000 parts and 2800 parts of orange peel; the three groups of raw materials were washed with water, and then soaked in an aqueous solution containing 1.5% sodium chloride mass fraction and 2.7% ethanol mass fraction for 4 hours, and ultrasonic treatment with a frequency of 25KHz , take it out and rinse it with pure water for 3 times, put it into a drier and dry it at a low temperature of 40°C until the water content is 6%, then put it into an ultrafine pulverizer and pulverize it to 100um to obtain composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com