Adenosylmethionine separating and purifying method

A technology for separation and purification of adenosylmethionine, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve problems such as easy inactivation reaction, poor stability of adenosylmethionine, limited application, etc., and achieve a high precipitation rate High, reduce impurity removal steps, improve the effect of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

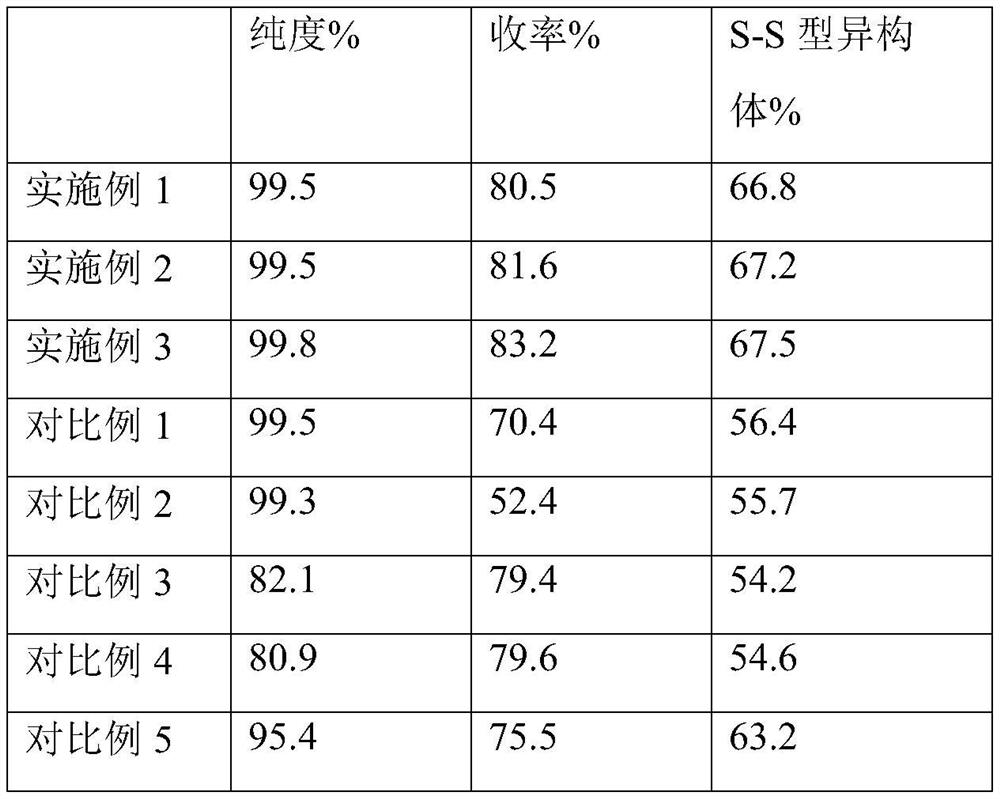

Examples

Embodiment 1

[0039] Embodiment 1 A kind of separation and purification method of adenosylmethionine

[0040] Include the following steps:

[0041] S1, wall breaking treatment: get 5mL of fermented liquid and carry out centrifugation, the centrifugation rate is 6000r / min, remove the supernatant, after washing, centrifuge again with the speed of 6000r / min to remove the supernatant, take the precipitate and add 6mL volume ratio 5: 1 solution of 0.1mol / L acetic acid and 0.6mol / L sulfuric acid, shake at room temperature for 60 minutes, centrifuge at a rate of 6000r / min, filter through a 0.22μm filter membrane, and keep the supernatant for later use;

[0042] S2, adjust the pH value of the supernatant obtained in step S1 to be 3, and then pass the mixed weakly acidic ion exchange resin with a volume ratio of 2:1 of D113 resin and D115 resin in series, using a concentration of 0.25mol / L of sulfuric acid to The flow velocity of 2BV / h is eluted, obtains adenosylmethionine sulfuric acid eluate;

...

Embodiment 2

[0044] Embodiment 2 A kind of separation and purification method of adenosylmethionine

[0045] Include the following steps:

[0046] S1, wall breaking treatment: get 5mL of fermented liquid and carry out centrifugation, the centrifugation rate is 8000r / min, remove the supernatant, after washing, centrifuge again with the speed of 8000r / min to remove the supernatant, take the precipitate and add 5mL volume ratio 10: 1 solution of 0.3mol / L acetic acid and 1.0mol / L sulfuric acid, shake at room temperature for 30 minutes, centrifuge at a rate of 8000r / min, filter through a 0.22μm filter membrane, and keep the supernatant for later use;

[0047] S2, adjust the pH value of the supernatant obtained in step S1 to be 5, and then pass the mixed weakly acidic ion exchange resin with a volume ratio of 3:1 of D113 resin and D115 resin in series, using a concentration of 0.3mol / L of sulfuric acid to The flow velocity of 3BV / h is eluted, obtains adenosylmethionine sulfuric acid eluate;

...

Embodiment 3

[0049] Embodiment 3 A kind of separation and purification method of adenosylmethionine

[0050] Include the following steps:

[0051] S1, wall breaking treatment: take 5 mL of fermented liquid and carry out centrifugation, the centrifugation rate is 7000r / min, remove the supernatant, after washing, centrifuge again with the speed of 7000r / min to remove the supernatant, take the precipitate and add 9mL volume ratio 8: 1 solution of 0.2mol / L acetic acid and 0.8mol / L sulfuric acid, shake at room temperature for 50 minutes, centrifuge at a rate of 7000r / min, filter through a 0.22μm filter membrane, and keep the supernatant for later use;

[0052] S2, adjust the pH value of the supernatant obtained in step S1 to be 4, and then pass the mixed weakly acidic ion exchange resin with a volume ratio of 3:1 of D113 resin and D115 resin in series, using a concentration of sulfuric acid of 0.25mol / L to The flow rate of 2.5BV / h is eluted to obtain ademetionine sulfuric acid eluate;

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com