Modified rubber particles as well as preparation method and application thereof

A technology for modifying rubber and rubber particles, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. phenomenon and other problems to achieve the effect of reducing the overall probability of failure, improving the surface quality and enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

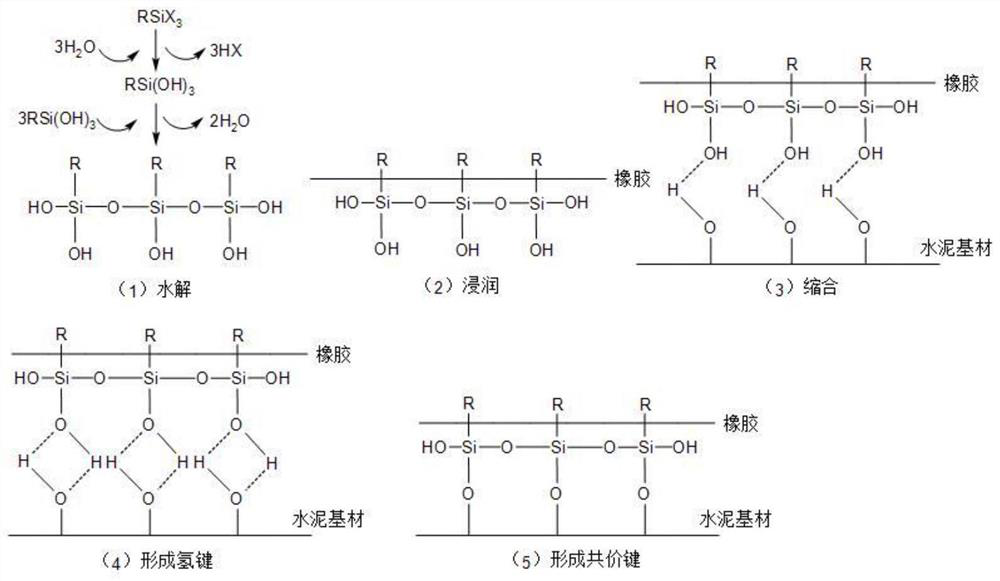

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] Step 1: Submerge 40 parts of rubber particles in NaCO with a mass concentration of 10% in parts by mass 3 Soak in the solution for 1h, then filter to obtain the filter residue;

[0035] Step 2, placing the filter residue obtained in step 1 in flowing clear water for 20 seconds;

[0036] Step 3. Submerge the washed filter residue in step 2 in clean water, then add 1 part of KH-560 in parts by mass and stir evenly. After standing still, filter and dry to obtain modified rubber particles.

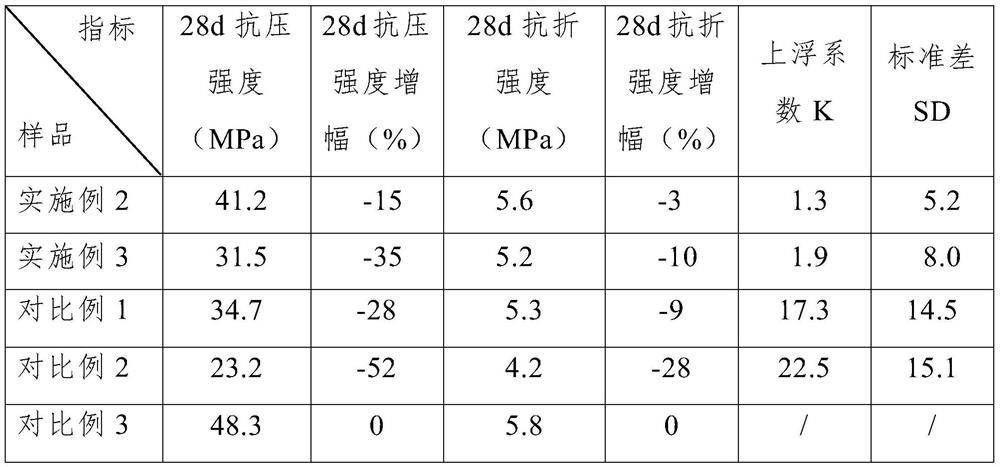

Embodiment 2

[0039] The application of this embodiment includes the following steps:

[0040] Step 1. Weigh and prepare raw materials according to the composition of the target product weakly floating rubber concrete. The raw materials for preparing the weakly floating rubber concrete in parts by mass are: cement: water: sand: crushed stone: water reducing agent: modified rubber particles =478:165:650:954:7.1:63, wherein the modified rubber particles are prepared from Example 1, and the modified rubber particles replace 20% of the sand by volume fraction to prepare weakly floating rubber concrete;

[0041] Step 2. Start the mixer, put the gravel, sand and modified rubber particles prepared in step 1 into the mixer in turn and stir for 30 seconds to make the raw materials mix evenly, then put in cement and stir for 10 seconds;

[0042] Step 3: Dissolve the water reducer in water and stir evenly to form a water reducer solution, then add it into the mixer after putting in the cement for mixi...

Embodiment 3

[0044] The application of this embodiment includes the following steps:

[0045] Step 1. Weigh and prepare raw materials according to the composition of the target product weakly floating rubber concrete. The raw materials for preparing the weakly floating rubber concrete in parts by mass are: cement: water: sand: crushed stone: water reducing agent: modified rubber particles =478:165:488:954:7.1:126, wherein the modified rubber particles are prepared from Example 1, and the modified rubber particles replace 40% sand by volume fraction to prepare weakly floating rubber concrete;

[0046] Step 2. Start the mixer, put the gravel, sand and modified rubber particles prepared in step 1 into the mixer in turn and stir for 30 seconds to make the raw materials mix evenly, then put in cement and stir for 10 seconds;

[0047] Step 3: Dissolve the water reducer in water and stir evenly to form a water reducer solution, then add it into the mixer after putting in the cement for mixing in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com