Novel mixed alkaline cement based on alkali-activated cementing material and Portland cement and preparation method of novel mixed alkaline cement

A technology of portland cement and cementitious materials, which is applied in cement production and other directions, and can solve the problems of poor soft water erosion resistance, sulfate corrosion resistance and chloride ion penetration resistance, fast setting and hardening speed, and influence on popularization and application. , to achieve the effects of good chloride ion penetration resistance, improved carbonization resistance and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

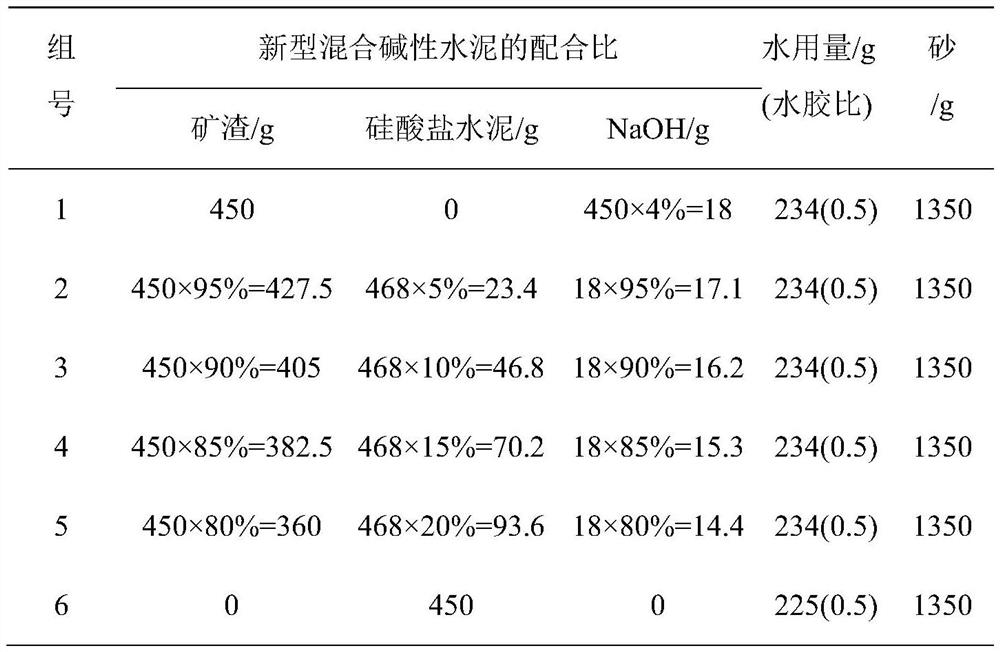

[0021] Example 1. Effect of Portland Cement Addition on the Properties of New Mixed Alkaline Cement

[0022] According to the proportions in Table 1, weigh the granulated blast furnace slag, 42.5-grade Portland cement and NaOH solid particles, then put the three raw materials into the mixer and mix them evenly, and the obtained mixture is mixed alkaline cement; Water and sand are added to the obtained mixed alkaline cement, and the mixture is continuously stirred to obtain a mortar specimen.

[0023]

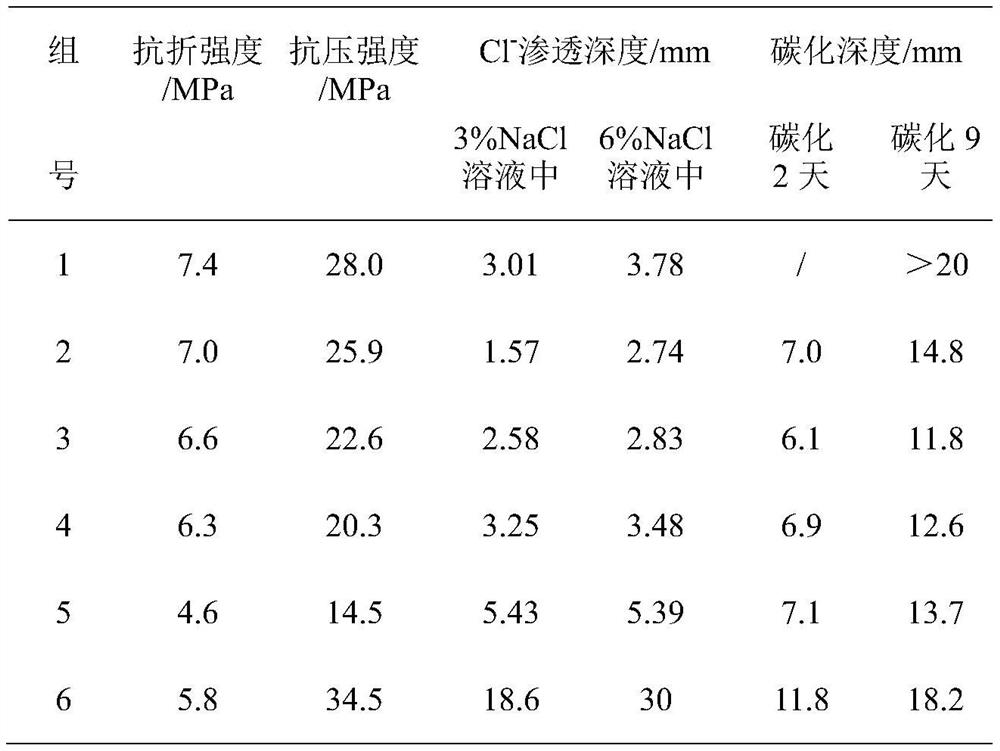

[0024] Mortar specimens with a size of 40mm×40mm×160mm formed from the proportions of groups 1 to 6 were placed in water at a temperature of (20±1)°C for 28 days, and then the flexural and compressive strengths of the specimens were measured. , the results are shown in Table 2, it can be seen that the strength of the mortar decreases after replacing part of the slag and NaOH in the slag cementitious material with the same amount of Portland cement, and the greater the amount ...

Embodiment 2

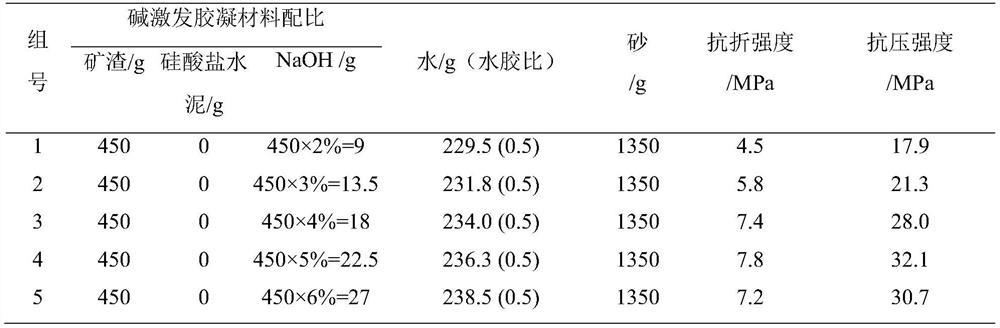

[0031] Example 2. Effect of NaOH addition on the strength of alkali-excited gelling materials

[0032] In order to understand the effect of NaOH content on the strength of alkali-induced cementitious materials, the mortar specimens with a size of 40mm × 40mm × 160mm were formed according to the proportions of each group in Table 3, and placed in water at a temperature of (20±1) ℃ for curing. After 28 days, the flexural and compressive strengths of the specimens were measured. The results are shown in Table 3.

[0033] Table 3 Proportion and strength value of alkali-excited cementitious material mortar

[0034]

[0035] It can be clearly seen from Table 3 that keeping the amount of slag and the water-binder ratio (water mass / (slag mass + NaOH mass)) unchanged, with the increase of NaOH content, the flexural and compressive strength of alkali-activated cementitious material mortar first gradually increases. When the NaOH content is 5%, the mortar strength reaches the maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com