Modification method for reducing residual alkali on surface of high-nickel ternary positive electrode material, prepared high-nickel ternary positive electrode material and lithium ion battery

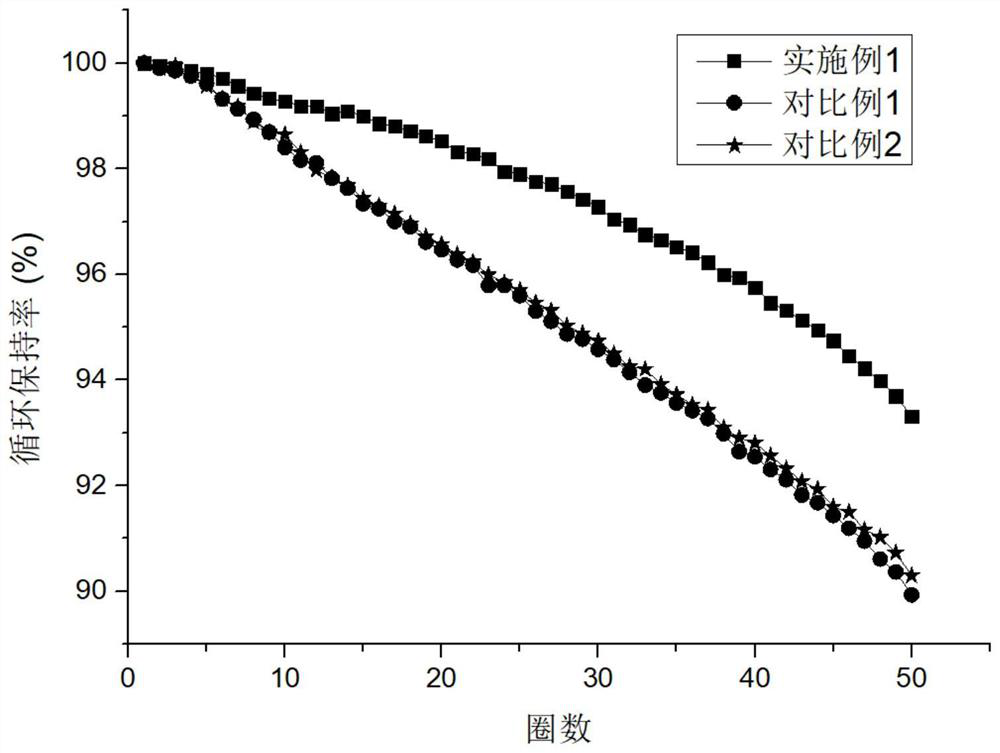

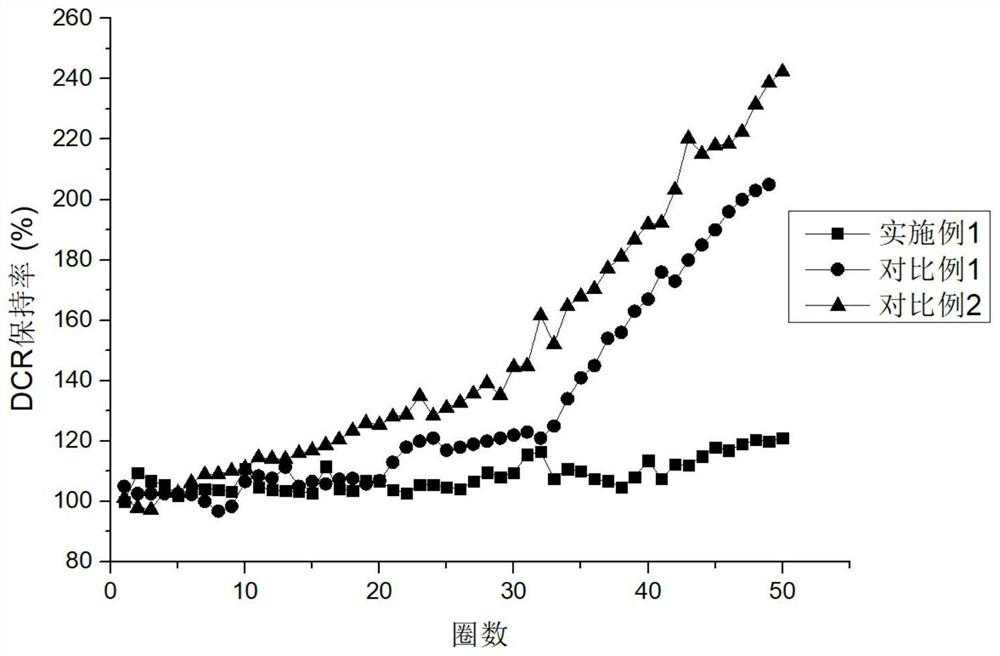

A positive electrode material, high-nickel technology, applied in the field of modification to reduce residual alkali on the surface of high-nickel ternary positive electrode materials, can solve the problems of uneven coating of slurry, unsuitable coating of high-nickel materials, swelling, etc., to achieve reduction High-temperature cycle DCR increases, improves high-temperature cycle performance and high-temperature storage performance, and reduces the effect of prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

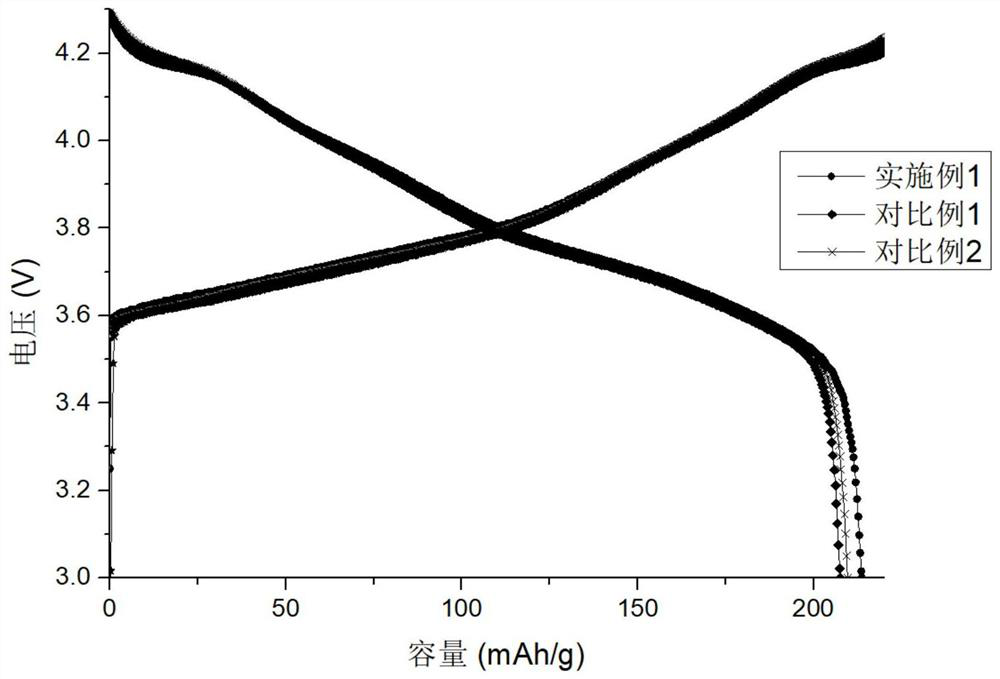

Embodiment 1

[0024] Select a high-nickel ternary cathode material after one-time sintering: LiNi 0.83 co 0.11 mn 0.06 o 2 As the material to be modified, take 2.5kg of deionized water and add it to the stirrer at a stirring speed of 100rpm, weigh 7.5kg of high-nickel ternary positive electrode material, quickly add it to the stirred deionized water, and increase the stirring speed to 500rpm , stirred for 3 minutes to form a thick slurry;

[0025] Transfer the viscous slurry to a positive pressure filter, rinse with 15kg deionized water for 10 minutes, and then press filter with a pressure of 0.3MPa for 15 minutes (after rinsing for 10 minutes, continue to press filter 5min); transfer the filtered material to a vacuum drying oven for vacuum drying at a drying temperature of 150°C and 2h; mix the dried material with the metal oxide coating agent MgO evenly, Transfer to an atmosphere box furnace for secondary sintering, the quality of the coating agent is 1% of the mass of the dried mater...

Embodiment 2

[0027] Select a high-nickel ternary cathode material after one-time sintering: LiNi 0.83 co 0.11 mn 0.06 o 2 As the material to be modified, take 7.5kg of deionized water and add it to the stirrer at a stirring speed of 100rpm, weigh 7.5kg of high-nickel ternary positive electrode material, quickly add it to the stirred deionized water, and increase the stirring speed to 500rpm , stirred for 3 minutes to form a thick slurry;

[0028] Transfer the viscous slurry to a positive pressure filter, rinse with 15kg deionized water for 10 minutes, and then press filter with a pressure of 0.3MPa for 15 minutes (after rinsing for 10 minutes, continue to press filter 5min); transfer the filtered material to a vacuum drying oven for vacuum drying at a drying temperature of 150°C and 2h; mix the dried material with the metal oxide coating agent TiO 2 After mixing evenly, transfer to an atmosphere box furnace for secondary sintering, the quality of the coating agent is 1% of the mass of ...

Embodiment 3

[0030] Select a high-nickel ternary cathode material after one-time sintering: LiNi 0.83 co 0.11 mn 0.06 o 2As the material to be modified, take 1.5kg of deionized water and add it to the stirrer at a stirring speed of 100rpm, weigh 7.5kg of high-nickel ternary positive electrode material, quickly add it to the stirred deionized water, and increase the stirring speed to 500rpm , stirred for 3 minutes to form a thick slurry;

[0031] Transfer the viscous slurry to a positive pressure filter, rinse with 15kg deionized water for 10 minutes, and then press filter with a pressure of 0.3MPa for 15 minutes (after rinsing for 10 minutes, continue to press filter 5min); the material after the press filtration is transferred to a vacuum drying oven for vacuum drying, the drying temperature is 150°C, and the drying temperature is 2h; the dried material is mixed with the metal oxide coating agent Al 2 o 3 After mixing evenly, transfer to an atmosphere box furnace for secondary sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com