An integrated device and method for forming and connecting metal edge wrapping of blades with variable thickness

A technology of metal edge wrapping and variable thickness, which is applied in the direction of coating, etc., can solve the problems of insufficient filling, uneven performance, and low forming efficiency, and achieve the effects of reducing excessive thinning, increasing forming limit, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

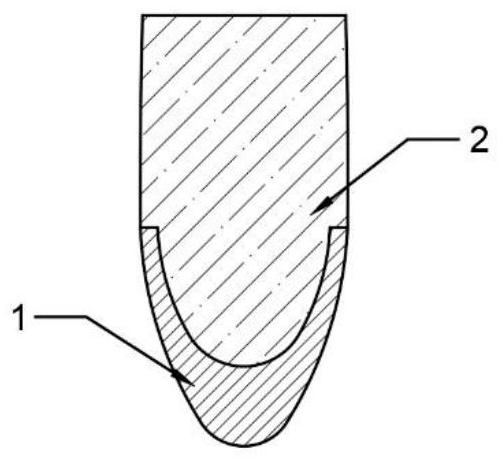

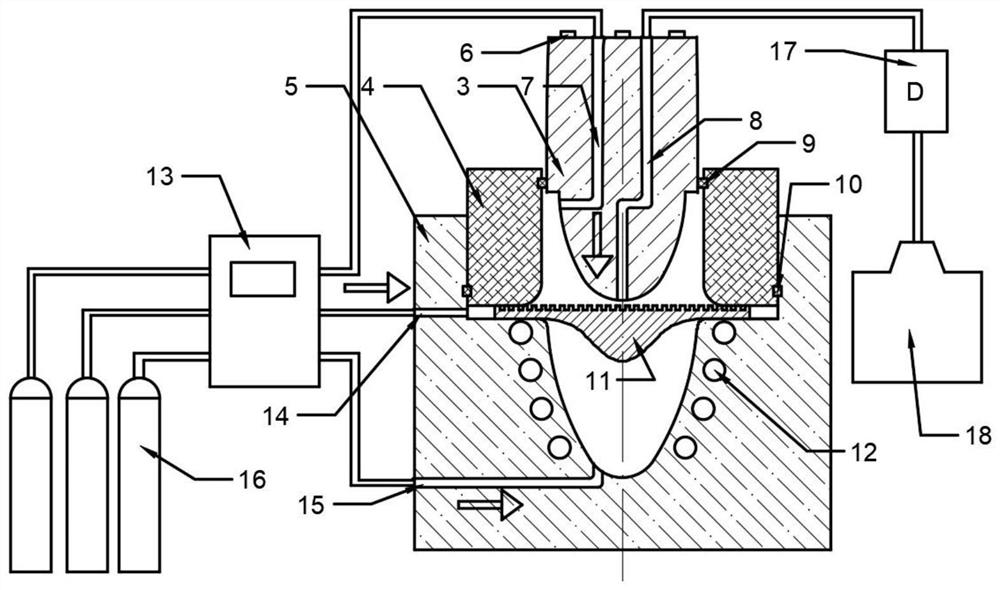

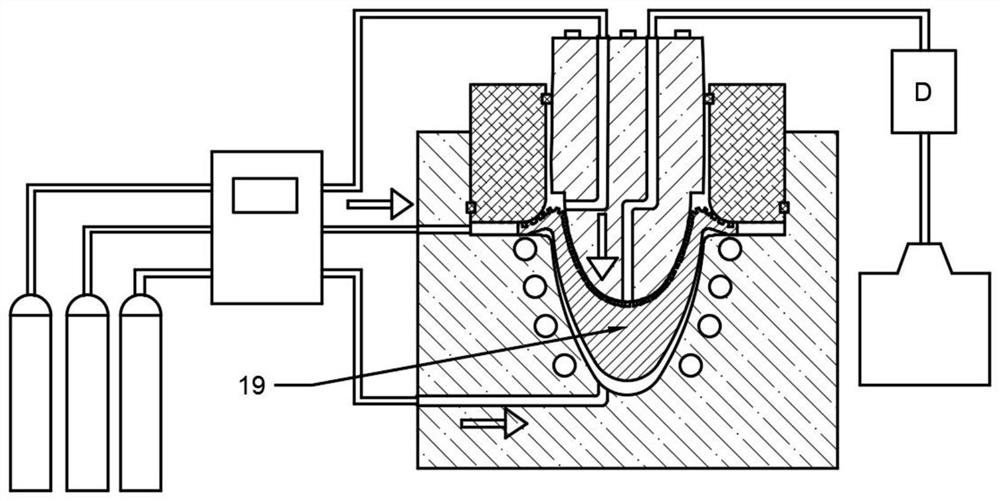

[0049] In the present embodiment, the metal sheet is selected of solid solution aluminum alloy, the thickness of the composite blade using thermoplastic (polyimide) carbon fiber composite material; the aluminum plate with the hemming is conventionally ground polishing, degreasing, rust removal, activation and other surface treatment, and the surface of the plate is slotted, the thickness of the sheet is 9mm, the thickness of the thickness is 35mm, the depth of the slot is 3mm; the prepared sheet is placed on the upper surface of the lower mold 5, and the longitudinal degree of freedom of the plate is fixed by the edge ring 4, At the same time, the flange of the edge 4 and the lower die 5 is sealed by the sealing ring, and the upper die 3 composite blade is also constrained by the sealing ring, and the entire forming cavity forms a sealing environment that can pass into the gas; after placing the upper mold 3 and the sheet, the aluminum plate is heated to 80 ° C by using the lower ...

Embodiment 2

[0052] In the present embodiment, the metal sheet is selected from solid solution aluminum alloy, the thickness of the composite blade adopts thermoset (epoxy resin) carbon fiber composite material; the aluminum plate with the edge is conventionally ground polished, degreased, rusted, activated and other surface treatment, and the surface of the plate is slotted, the thickness of the sheet is 10mm, the thickness of the thickness of the thick is 36mm, and the groove depth is 4mm; the prepared sheet is placed on the upper surface of the lower mold 5, and the longitudinal degree of freedom of the plate is constrained by the edge ring 4, At the same time, the flange of the compression ring 4 and the lower mold 5 is sealed by the sealing ring, and the upper mold 3 composite blade is also constrained by the sealing ring, and the entire forming cavity forms a sealing environment that can pass into the gas; after placing the upper mold 3 and the sheet, the aluminum plate is heated to 75 °...

Embodiment 3

[0055] In the present embodiment, the metal sheet metal is selected of solid solution titanium alloy, the thickness of the composite material blade using thermoplastic (polyimide) carbon fiber composite material; the titanium plate with the hemming is conventionally ground polished, degreased, rusted, activated and other surface treatment, and the surface of the plate is slotted, the thickness of the sheet is 10mm, the thickness of the thickness is 38mm, the depth of the slot is 4mm; the prepared sheet is placed on the upper surface of the lower mold 5, and the longitudinal degree of freedom of the plate is fixed by the edge ring 4, At the same time, the flange of the crimp 4 and the lower mold 5 is sealed by the sealing ring, and the upper mold 3 composite blade is also constrained by the sealing ring, and the entire forming cavity forms a sealing environment that can pass into the gas; after placing the upper mold 3 and the sheet, the titanium plate is heated to 85 ° C by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com