Process for preparing bonding resin

A technology for bonding resin and diglycidyl ether, applied in the direction of adhesive type, lignin adhesive, lignocellulosic material adhesive, etc., can solve the problems of long pressing time, high pressing temperature and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, a lignin solution was prepared by adding 182 g of powdered lignin (90% solid content) and 257 g of water to a 1 L glass reactor at ambient temperature, and stirring until the lignin was fully and uniformly dispersed. Then, 60 g of a 50% alkaline solution were added to the lignin dispersion. The composition was stirred for 120 minutes to ensure complete dissolution of the lignin in the alkaline medium.

Embodiment 2

[0026] The adhesive formulation was prepared by mixing 30.3 g of the lignin alkaline solution from Example 1 and 10 g of glycerol diglycidyl ether (Sigma Aldrich) in a beaker for 20 minutes at room temperature using an overhead stirrer.

[0027] The adhesive formulations were tested according to standard test method EN 205:2016. The target binder resin content is 150g / m 2 , spread on one side with a coil applicator. Hot pressing was performed at 150° C. at a pressure of 1.8 MPa. The total pressing time was 5 minutes. All samples were conditioned according to EN12765:2016C2 before evaluation. The average data from the 10 conditioned and unconditioned samples are listed in Table 1 .

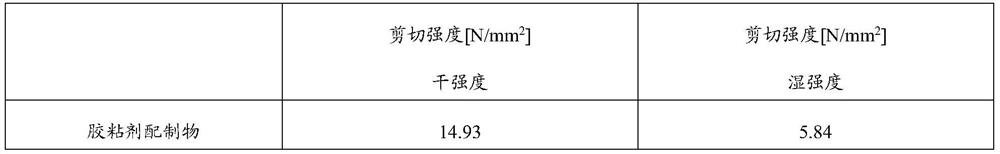

[0028] Table 1: Dry Shear Strength and Wet Shear Strength

[0029]

Embodiment 3

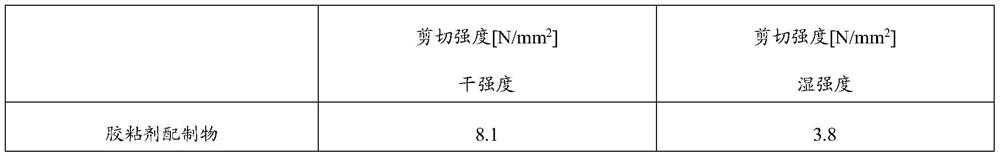

[0030] Embodiment 3 (comparative example)

[0031] The adhesive formulation was prepared by mixing 30 g lignin and 30 g glycerol diglycidyl ether in a beaker for 20 minutes at room temperature using an overhead stirrer.

[0032] The adhesive formulations were tested according to standard test method EN 205:2016. The target binder resin content is 150g / m 2 , spread on one side with a coil applicator. Hot pressing was performed at 150° C. at a pressure of 1.8 MPa. The total pressing time was 5 minutes. Most of the samples fell apart after hot pressing. The pressing time was insufficient to fully cure the samples and, moreover, a longer time was required to cure than the system described in Example 2, which fully cured at 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com