Silicon-based polarization beam splitting rotator based on adiabatic cone asymmetric coupling and Y branch

An asymmetric coupling and polarization beam splitting technology, which is applied in the direction of instruments, light guides, optics, etc., can solve the problems of small device manufacturing tolerance, poor polarization separation, and low polarization extinction ratio, and achieve a large working wavelength range and large production Effect of Tolerance, High Extinction Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

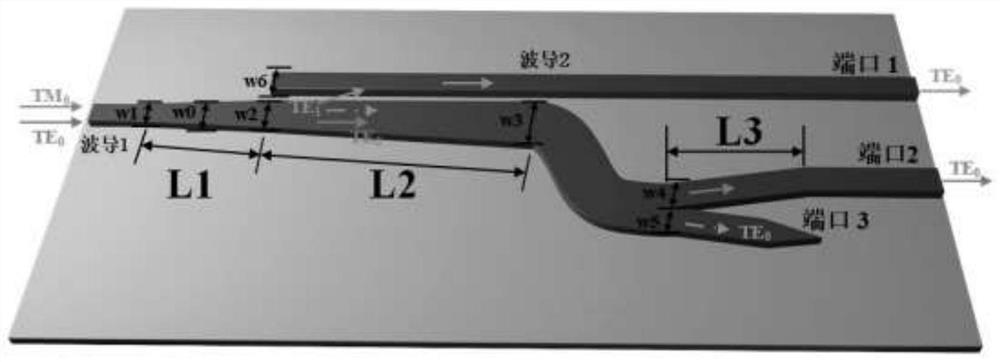

[0030] Silicon-based polarization beam splitting rotator based on adiabatic tapered asymmetric coupling and Y branch of the present invention such as figure 1 As shown, silicon dioxide is used as the substrate and the cladding layer; a buffer layer of silicon material is added between the substrate and the cladding layer, and a ridge waveguide is constructed on the buffer layer to form the main body of the polarization beam splitter rotator.

[0031] The above-mentioned ridge waveguide consists of three sections:

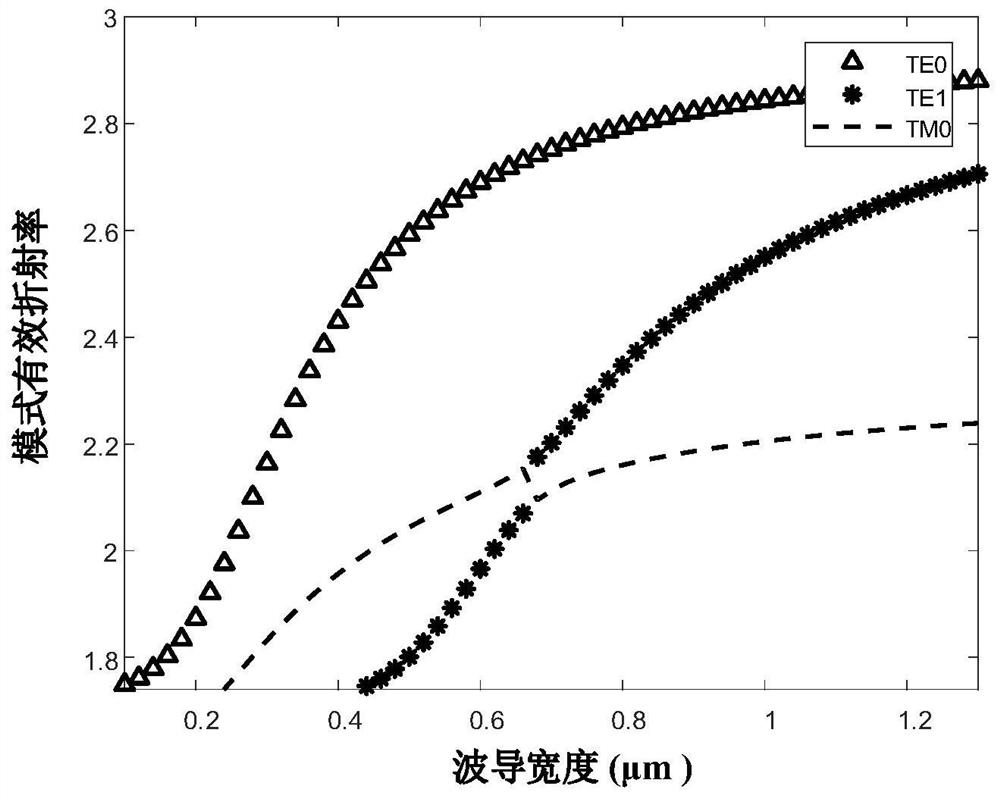

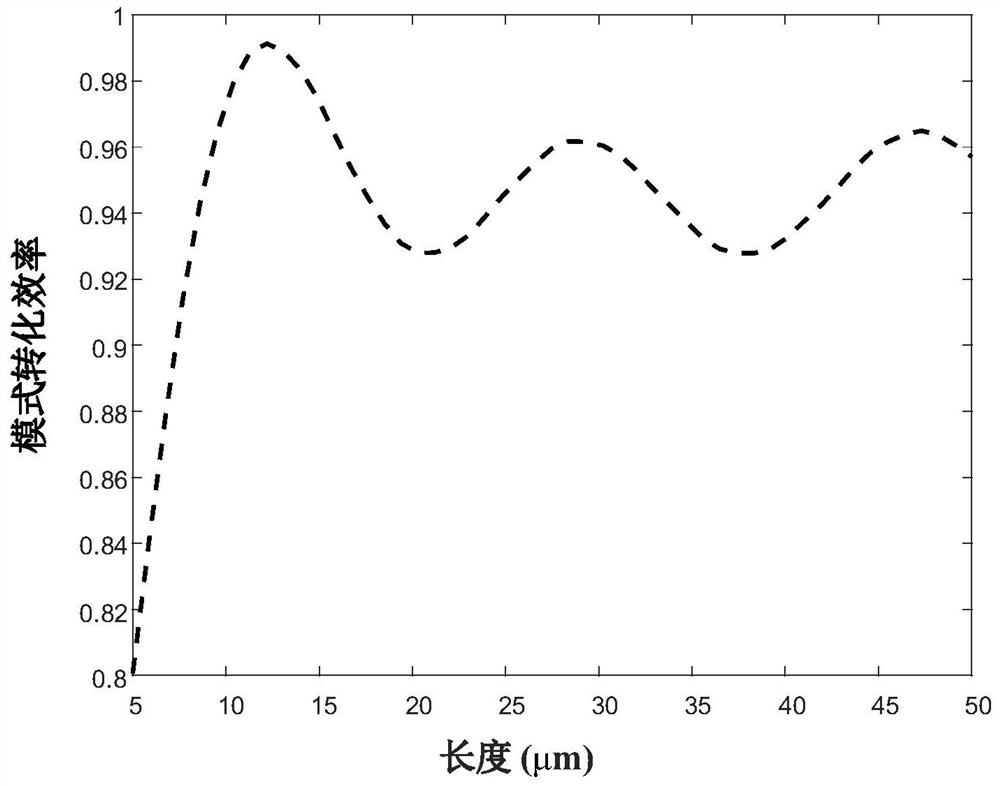

[0032] The first section is an adiabatic conical structure with a width from W 1 fade to W 2 , after the polarization mode conversion critical width W in the gradient process 0 , implementing TM inside the waveguide 1 0 polarization mode to TE 1 Conversion of polarization modes.

[0033] The second section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com