Rear wheel axle structure and mounting method

An installation method and a rear axle technology, applied in the field of motorcycle parts, can solve the problems of large influence, complicated process, difficult to ensure the verticality of the processing pressure surface and the long axis axis, and achieve the reduction of the bolt length, the simple production process and the small gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of this specific embodiment is to provide a rear wheel shaft structure, which improves the rear wheel shaft, simplifies the manufacturing process, and solves the current problems in this field.

[0030] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

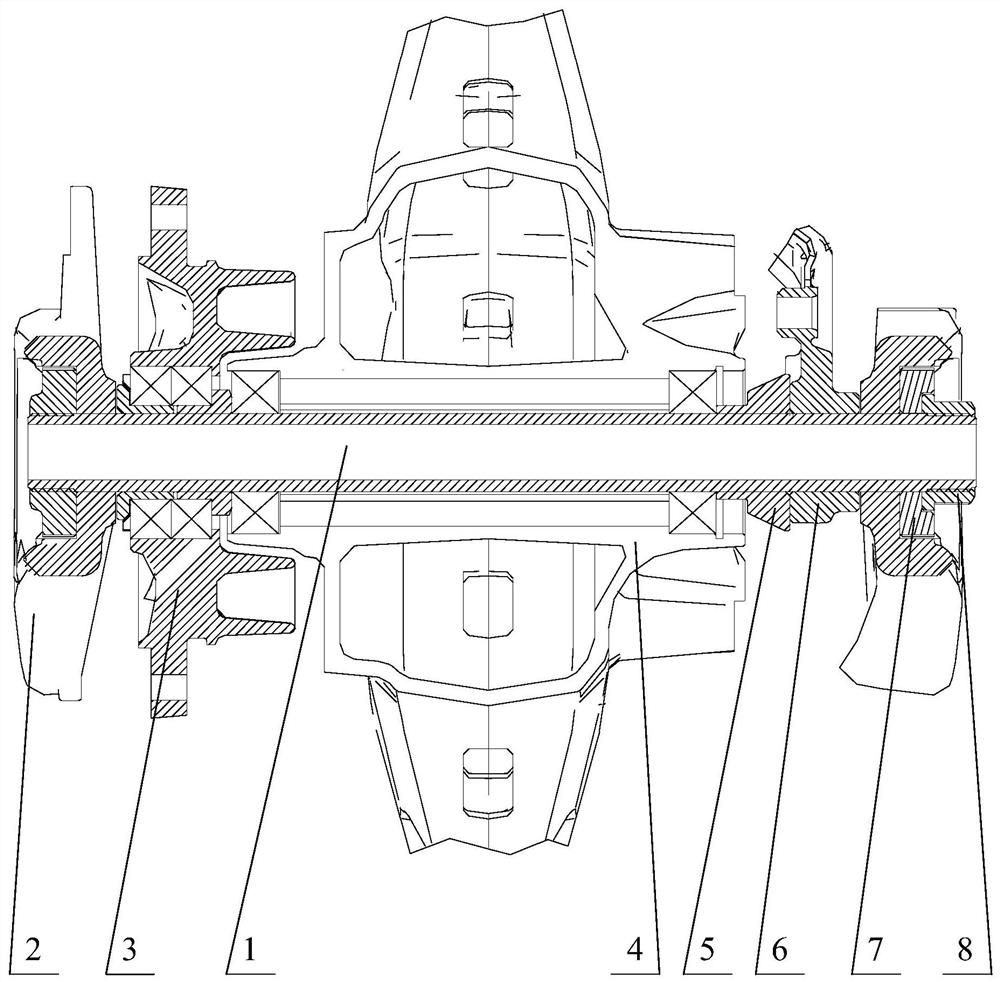

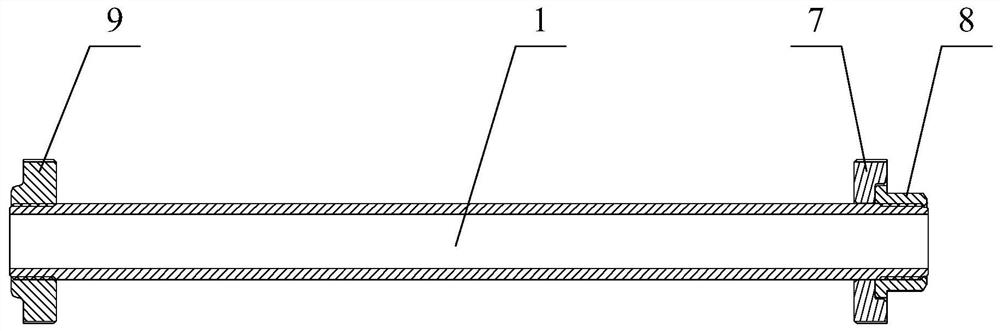

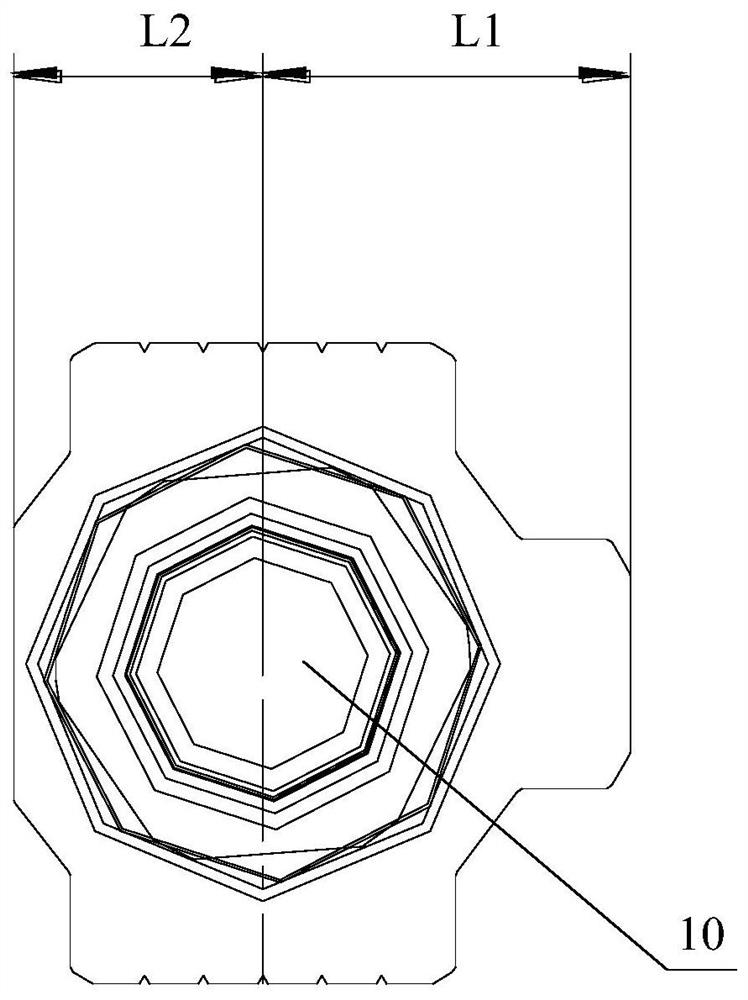

[0031] Please refer to figure 1 and figure 2 , the rear wheel shaft structure provided in this specific embodiment includes a rear wheel shaft 1, a rear rocker arm 2, a sprocket seat assembly 3, a rear wheel rim assembly 4, a rear wheel right bushing 5, a caliper bracket 6, and a right adjustment block 7 assembled in sequence And wheel shaft fastening nut 8, also includes the fastener that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com