Low-temperature-resistant PC alloy material and preparation method thereof

An alloy material, low temperature resistance technology, applied in the field of engineering plastics, can solve the problems of reducing material toughness or low temperature resistance, limiting the use range of materials, affecting the flame retardant performance of resin, etc., to improve toughness and low temperature toughness, reduce interface voiding , Improve the effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

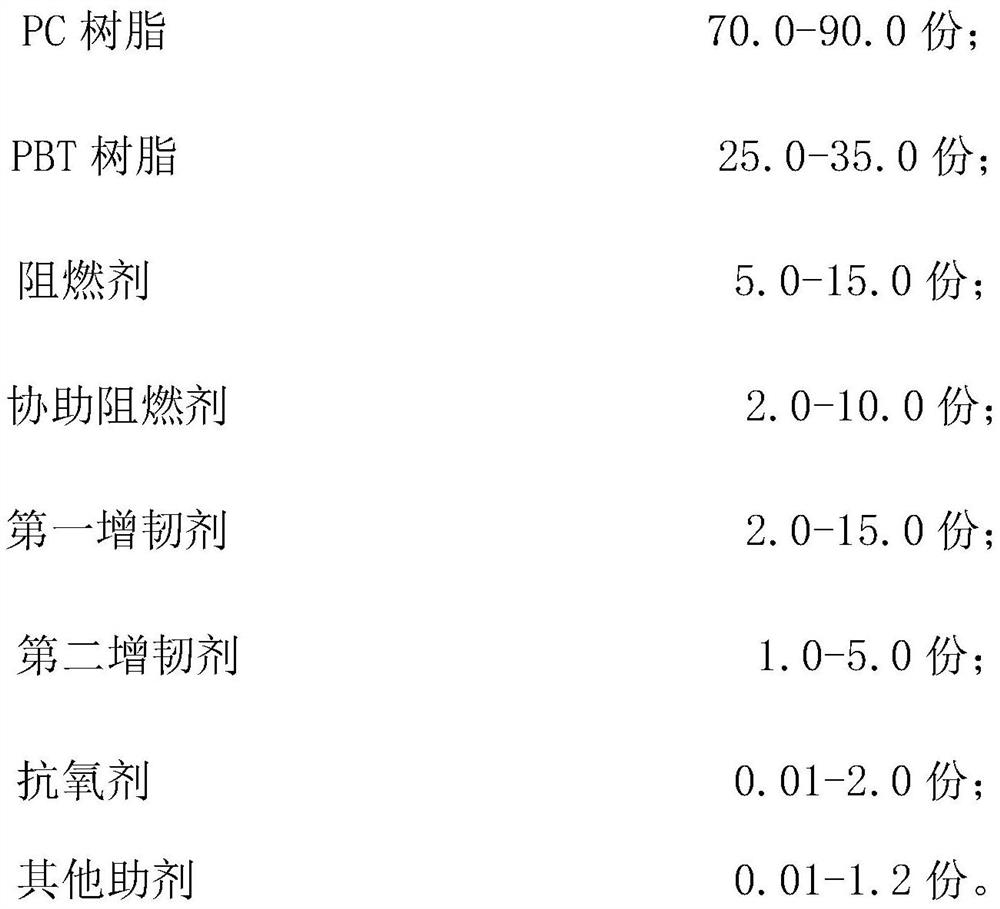

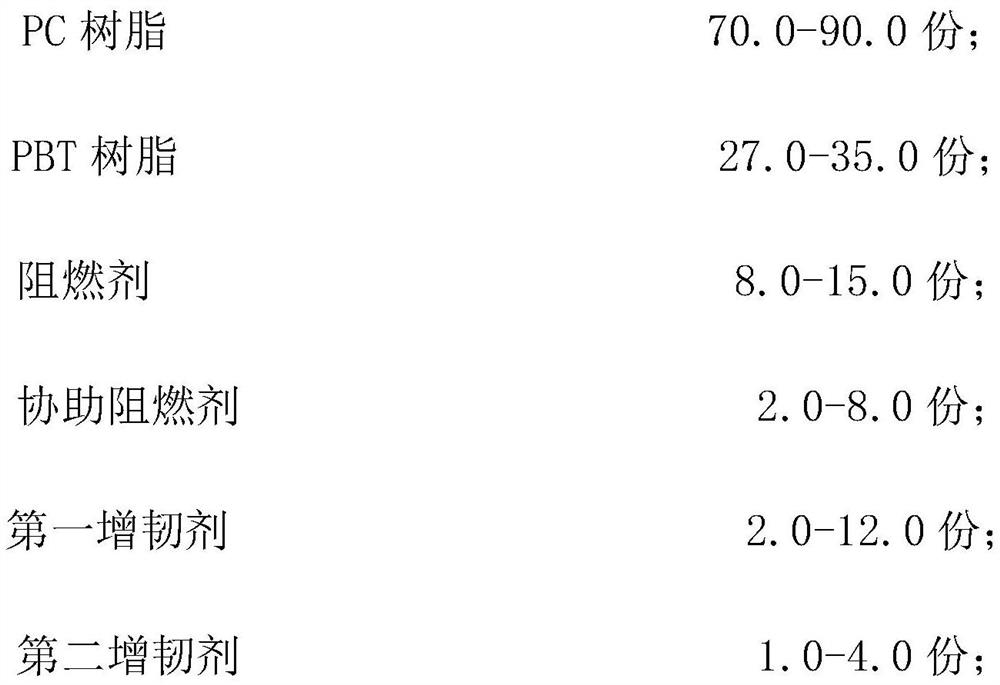

Method used

Image

Examples

Embodiment Construction

[0029] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0030] The present invention is described in detail below in conjunction with embodiment.

[0031] The PC resin uses PC S-2000F (Mitsubishi Japan) with a viscosity average molecular weight of 22,000; the PBT resin uses medium-viscosity PBT GX121 (Yizheng Petrochemical); the flame retardant uses RDT-7 (Weidong Chemical); other flame retardants use F -2100 (ICL) and FP-600 (Aidike); the first toughening agent is S-170H of Tailong Chemical (volume average particle size 350nm, rubber content 32%); the other first toughening agent is Mitsubishi Li Yang’s S-2001; the second toughening agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com