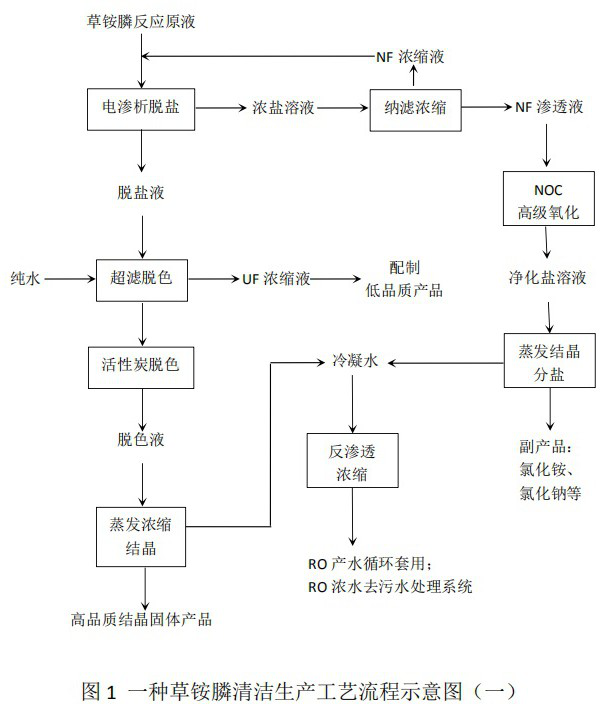

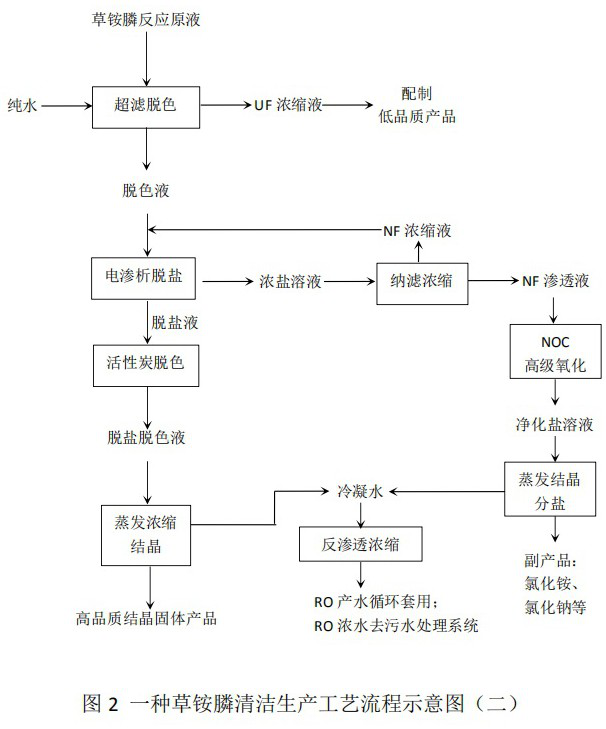

Glufosinate-ammonium clean production process and method thereof

A clean production, glufosinate-ammonium technology, applied in chemical instruments and methods, ammonium chloride, ammonium halide, etc., can solve the problems of increasing membrane processing capacity, large equipment investment, large land occupation, etc. The effect of reducing equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A glufosinate-ammonium ammoniation reaction stock solution, its glufosinate-ammonium content is 22wt%, inorganic salt (mainly sodium chloride and ammonium chloride) content is 16wt%, solution pH6.0, chromaticity value 660 (diluted with pure water 10 times).

Embodiment 2

[0052] The glufosinate-ammonium stock solution in Example 1 was directly subjected to nanofiltration without dilution.

[0053] The nanofiltration membrane used has a molecular weight cut-off of 500Da, operating conditions: material temperature 30°C, membrane inlet pressure 4.0MPa, permeation flow rate 0LMH, and cannot be processed.

Embodiment 3

[0055] The glufosinate-ammonium stock solution in Example 1 was directly subjected to nanofiltration without dilution.

[0056] The nanofiltration membrane used has a molecular weight cut-off of 1000Da, operating conditions: material temperature 30°C, membrane inlet pressure 4.0MPa, permeation flow rate 0LMH, and cannot be processed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com