Fastening method and fastening device for fuel cell stack, and fuel cell

A technology for fuel cell stacks and fastening devices, which can be applied to fuel cells, circuits, electrical components, etc., and can solve the problems of large tension tolerance of cable ties, uneven pressure distribution, and sacrifice of stack power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

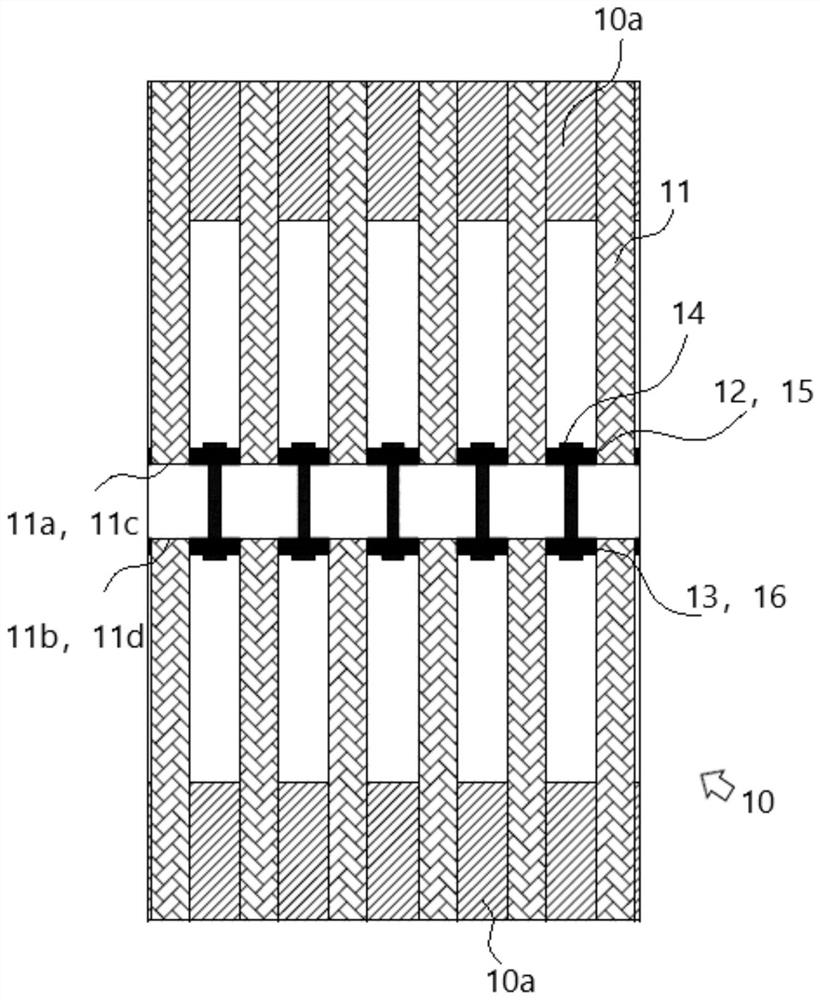

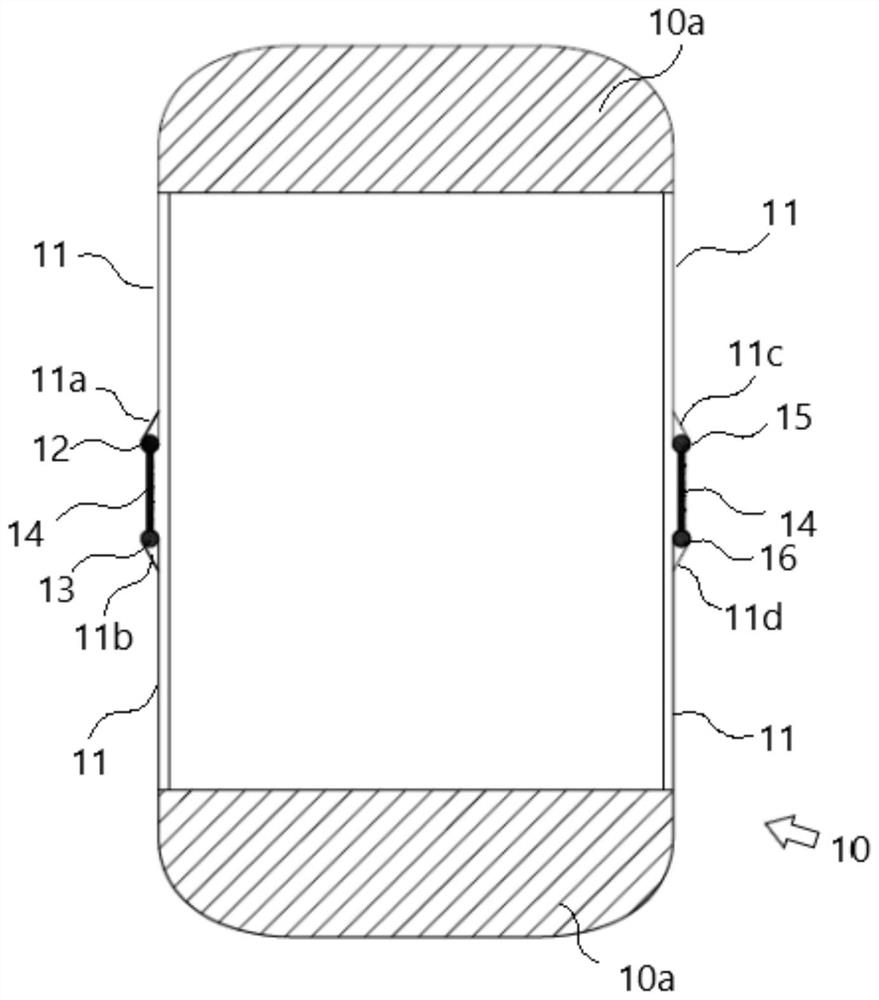

[0039] Example 1: see figure 1 and figure 2 As shown, a fuel cell includes a fuel cell stack 10, and the fuel cell stack 10 includes one or more single cells stacked together (the specific number is conventionally selected according to the design of the stack), wherein the single cell includes an anode plate, membrane electrode and cathode plate, the anode plate or cathode plate adopts silicon pole plate or graphite pole plate or metal pole plate or ceramic pole plate or composite material pole plate, and pole plates of other suitable materials can also be used. There is no specific limit.

[0040] The fastening method of the fuel cell stack 10 in this embodiment includes: applying pressure to the fuel cell stack 10 in advance and keeping the pressure before winding the strap unit 11; Unit 11 ( figure 2 6 ring-shaped cable tie units 11 are shown, and the specific number can be selected according to the axial length requirements of the stack 10 and the internal pressure di...

Embodiment 2

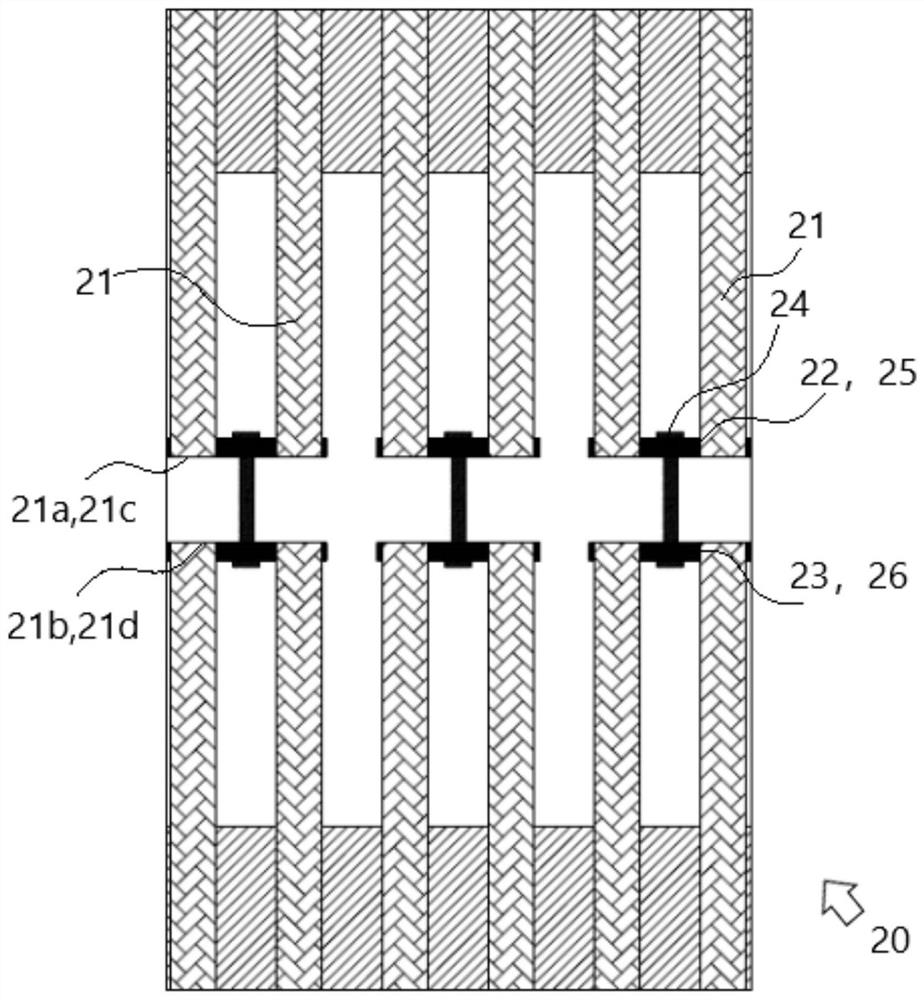

[0047] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that please refer to image 3 and Figure 4 As shown, in the second embodiment, there are six cable tie units 21 arranged in adjacent parallel intervals around the outer circumference of the fuel cell stack 20, wherein every two cable tie units 21 are arranged in adjacent parallel intervals A single connecting rod installation fastening group is formed, and a total of three connecting rod installation fastening groups are formed, wherein the first connecting rod 22, the second connecting rod 23, the third connecting rod 25 and the fourth connecting rod 26 each include three separate Segment connecting rod units, each segment connecting rod unit is fastened and installed and connected by fasteners 24;

[0048] Wherein, the first end portion 21a and the second end portion 21b of each strap unit 21 in the single connecting rod installation and fast...

Embodiment 3

[0049] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as embodiment 1 or embodiment 2, the difference is that please refer to Figure 5 As shown, the present embodiment 3 proposes an end plate 30a of a fuel cell stack 30, which is located at both ends of the fuel cell stack, and the outer periphery of the end plate 30a is provided with a cable tie unit 32 (see Image 6 , Figure 7 and Figure 8 ) the cable tie groove 31 with sliding limit fit to prevent the cable tie unit 32 from moving in its axial direction relative to the fuel cell stack 30; preferably, in this embodiment, the groove depth range of the cable tie groove 31 is 0.01-5mm; the groove width range of the cable tie groove 31 is 0.1-20mm, and the actual size specification of the cable tie groove 31 is specifically set according to the corresponding cable tie unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com