Passive residual heat removal heat pipe heat exchange system for spent fuel pool

A spent fuel pool, passive waste heat technology, applied in indirect heat exchangers, nuclear power generation, lighting and heating equipment, etc., can solve problems such as dry burning of evaporation tubes, achieve equal pipeline resistance, overcome the increase in saturation temperature, and have Conducive to the effect of uniform distribution of steam flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

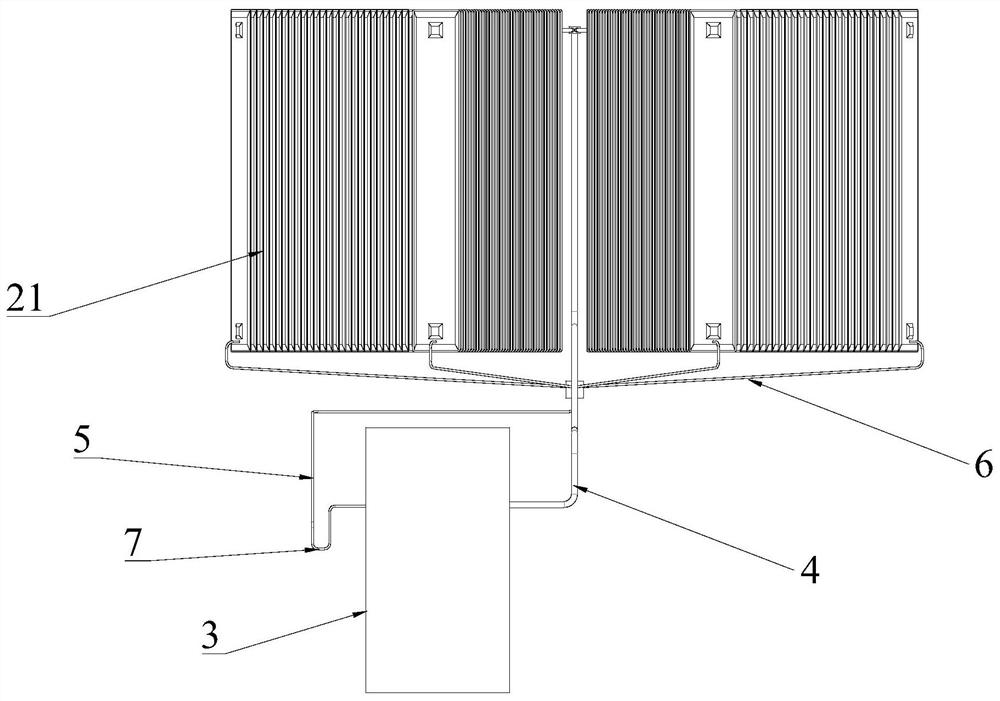

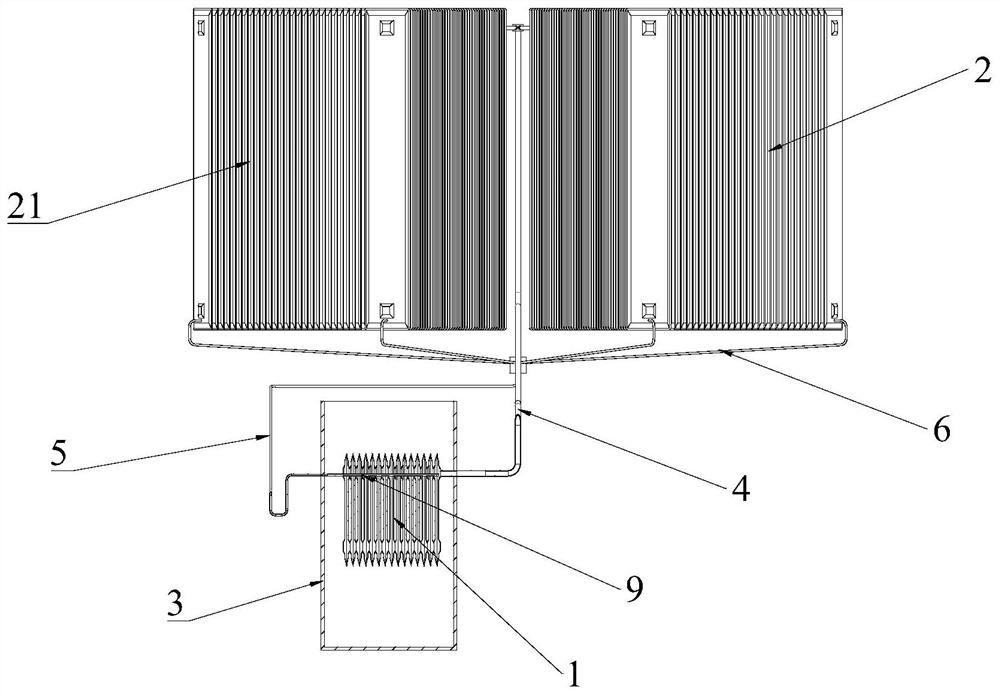

[0077] Such as Figure 1 to Figure 10 As shown, this embodiment provides a spent fuel pool passive waste heat export heat pipe heat exchange system, the system includes an evaporator 1 and a condenser 2, the evaporator 1 is immersed in the water of the spent fuel pool 3; the condenser 2 is set in the spent fuel pool Outside the fuel pool 3, the condenser 2 includes several condensing units 21, which are arranged in parallel; the evaporator 1 and the condenser 2 are connected through the steam main pipe 4 and the condensate main pipe 5, forming a closed circulation heat pipe heat exchange circuit; Both the steam header 4 and the condensate header 5 communicate with the upper part of the evaporator 1 .

[0078] Specifically, such as Figure 4 with Figure 5 As shown, the evaporator 1 includes a plurality of sequentially connected evaporating sheets 11 , the evaporating sheets 11 are stamped and formed by a 1 mm thick stainless steel plate, and then the inner and outer edges ar...

Embodiment 2

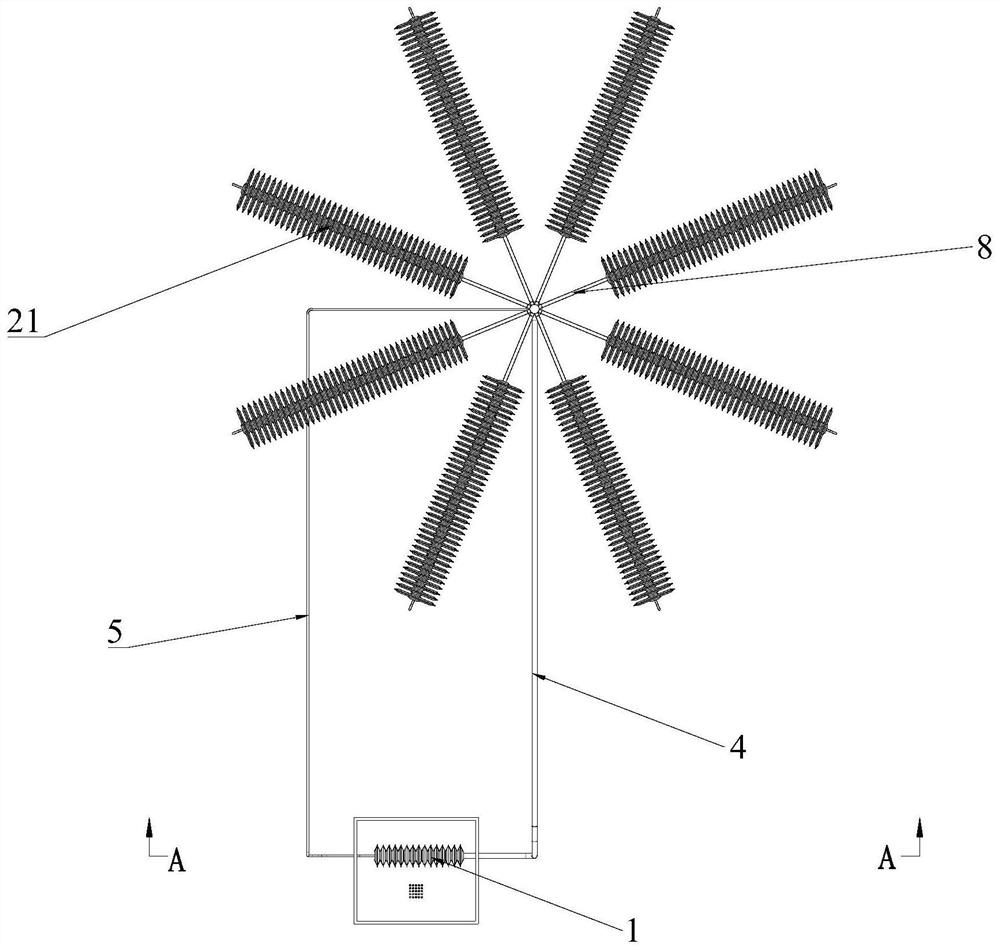

[0085] Such as figure 1 with figure 2 As shown, this embodiment is a further supplement to Embodiment 1. Several condensing units 21 are radially dispersed and arranged in parallel. A cold end condenser 2 heat transfer performance.

[0086] Preferably, the condensate collection pipe 6 has a downward slope between the condensate flow direction and the horizontal plane, and several condensate collection pipes 6 are distributed radially on a conical surface; it is beneficial to the collection of condensate, as the most preferred embodiment of this embodiment Preferably, the slope is not less than 10°; the collecting pipe of the condenser 2 is connected with the condensate main pipe 5 through the condensate collecting pipe;

[0087] Further, several steam distribution pipes 8 are distributed radially, on a horizontal plane or on the same conical surface. Since the steam distribution pipe 8 is located in the radial center, the temperature is higher, so the pressure in the radial ...

Embodiment 3

[0089] Such as Figure 10 As shown, the difference between the present embodiment and the second embodiment is that several condensing units 21 are arranged in parallel;

[0090] Preferably, the condensate collecting pipes 6 are arranged in parallel and vertically, and are sequentially collected and communicated with the condensate main pipe 5;

[0091] Preferably, the steam distribution pipes 8 are arranged in parallel.

[0092] Specifically, if the layout space of the condenser 2 is limited, the condensing units 21 can also be arranged in parallel and in parallel, that is, the condensing units 21 are arranged in parallel with each other at a certain interval, and each steam distribution pipe 8 is perpendicular to the steam main pipe 4, and the steam enters each steam pipe from the main pipe in turn. Steam distribution pipe 8. The condensing units 21 are arranged in parallel and in parallel. This arrangement is compact and regular, and is suitable for the condition of limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com