Bio-based polyurethane with photothermal dual repair function and preparation method thereof

A polyurethane and bio-based technology, applied in the field of bio-based polyurethane and its preparation, can solve problems such as poor mechanical properties, achieve good repair, and enhance the effect of rapid repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

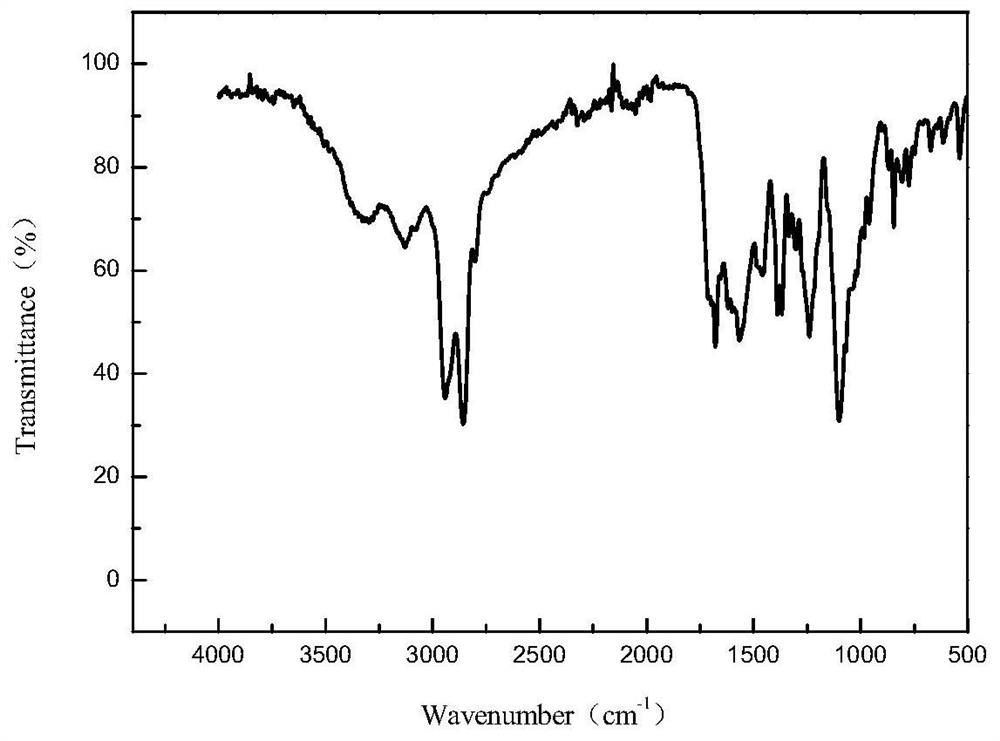

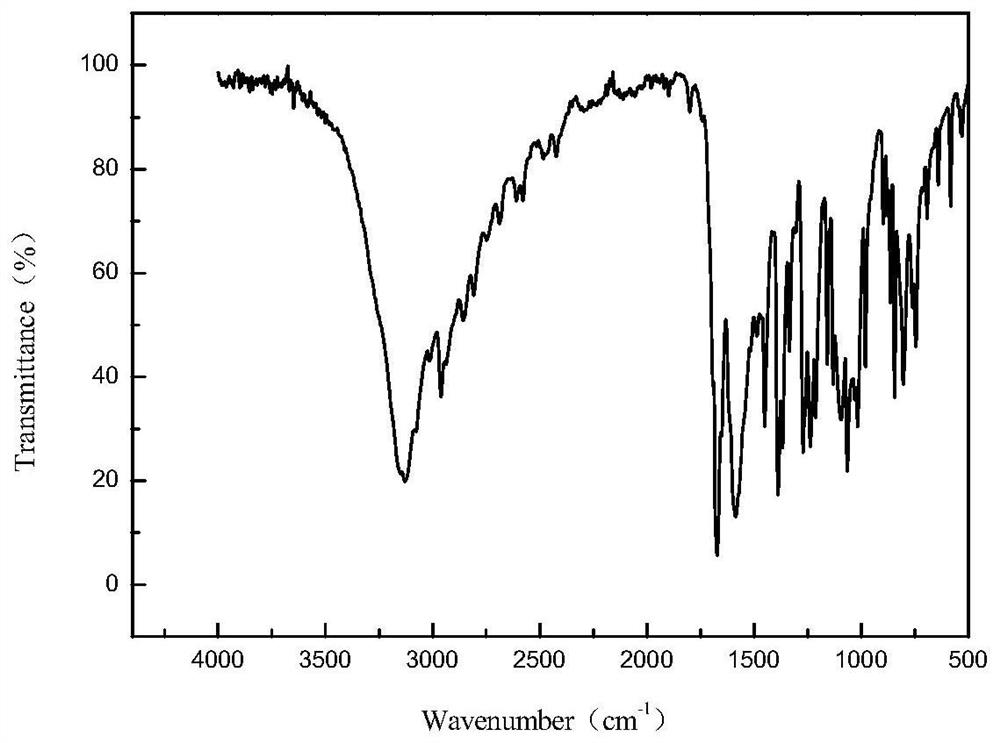

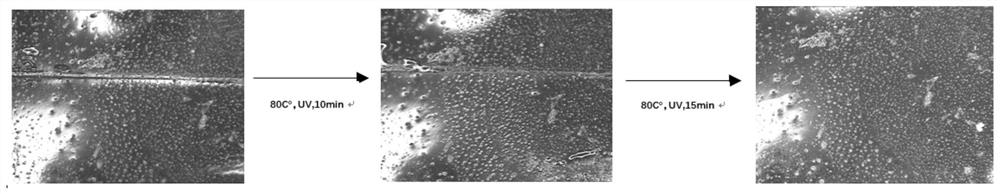

Embodiment 1

[0034]Take 6.00 g of polytetrahydrofuran (the hydroxyl value is between 100-120 mgKOH / g, Mn=1000) dissolved in 2 ml of N, N-dimethylformamide after dehydration treatment at 100 ° C for 3 hours, and repeatedly treat it in vacuum and nitrogen In three 100ml three-neck flasks, add isophorone diisocyanate (4g), then add dibutyltin dilaurate (0.018g) dissolved in 2ml N,N-dimethylformamide, and react at 80°C for 2h to obtain a viscous isocyanate-terminated polyurethane prepolymer PU-1; add L-cystine (1.44g) dissolved in 3.5ml N,N-dimethylformamide, and react at 45°C for 1h to obtain viscous disulfide-containing The isocyanate-terminated polyurethane PU-2 of the bond; then add 4-methylumbelliferone (2.11g) dissolved in 2.5ml N,N-dimethylformamide, and react at 40°C for 1h to obtain a viscous Sulfur-bonded coumarin derivative monomer-capped polyurethane PU-3; weigh 2g of nano-scale graphite powder, add graphite to 2ml of absolute ethanol with a content ≥99.7%, and then ultrasonically ...

Embodiment 2

[0039] Take 6.00 g of polytetrahydrofuran (the hydroxyl value is between 100-120 mgKOH / g, Mn=1000) dissolved in 2 ml of N, N-dimethylformamide after dehydration treatment at 100 ° C for 3 hours, and repeatedly treat it in vacuum and nitrogen In three 100ml three-neck flasks, add isophorone diisocyanate (4g), add dibutyltin dilaurate (0.018g) dissolved in 2ml N,N-dimethylformamide, and react at 80°C for 2h to obtain a viscous Isocyanate-terminated polyurethane prepolymer PU-1; add 4,4'-diaminodiphenyl disulfide (1.49 g) dissolved in 3.5 ml N, N-dimethylformamide, and react at 40 ° C for 1 h to obtain Viscous disulfide bond-containing isocyanate-terminated polyurethane PU-2; add 4-methylumbelliferone (2.11g) dissolved in 2.5ml N, N-dimethylformamide, and react at 40°C for 1h to obtain Viscous disulfide bond-containing coumarin derivative monomer-terminated polyurethane PU-3; weigh 2g of nano-scale graphite powder, add graphite to 2ml of absolute ethanol with a content ≥ 99.7%, a...

Embodiment 3

[0044] Take 11.46g of polytetrahydrofuran (Mn=2000) dissolved in 2ml of N,N-dimethylformamide after dehydration treatment at 100°C for 3 hours, and put it into a 100ml three-necked flask that has been repeatedly treated with vacuum and nitrogen for three times, and add Isophor Ketone diisocyanate (3.82g), add dibutyltin dilaurate (0.033g) dissolved in 2ml N, N-dimethylformamide, and react at 85°C for 2h to obtain viscous isocyanate-terminated polyurethane prepolymer PU -1; add L-cystine (1.38g) dissolved in 3.5ml N,N-dimethylformamide, and react at 40°C for 1h to obtain viscous disulfide-bonded isocyanate-terminated polyurethane PU-2 ; Add 4-methylumbelliferone (2.02g) dissolved in 2.5ml N, N-dimethylformamide, and react at 45°C for 1h to obtain viscous disulfide bond-containing coumarin derivative monomer-terminated Polyurethane PU-3; Weigh 2g of nanoscale graphene powder, add graphene to 2ml of absolute ethanol with a content ≥ 99.7%, then ultrasonically treat it in an ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com