Thickened oil viscosity reducer as well as preparation method and application thereof

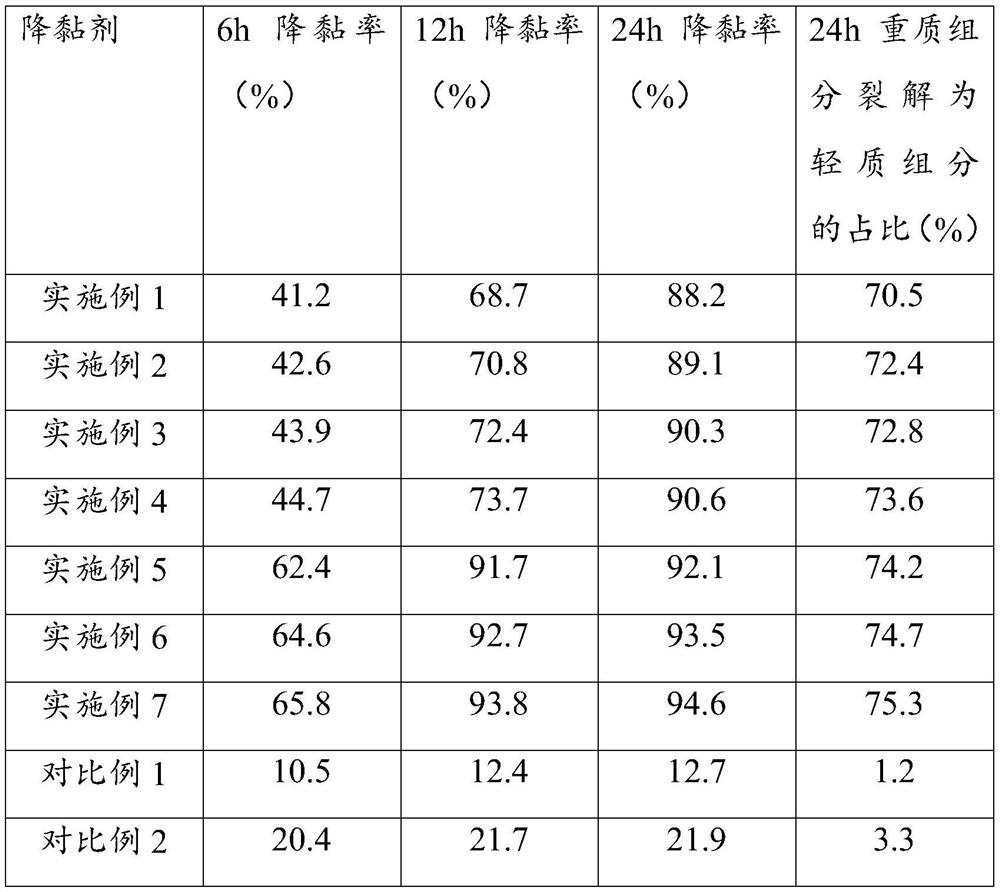

A technology of viscosity reducer and heavy oil, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of low viscosity reduction efficiency of heavy oil and achieve the effect of increasing viscosity reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

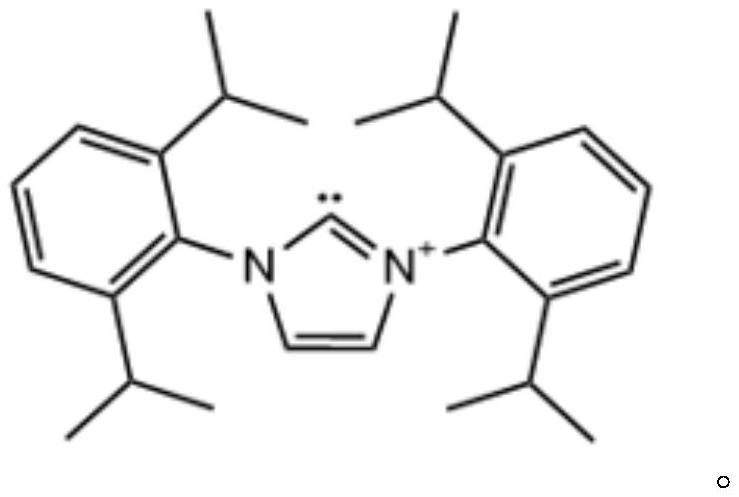

[0035] This example proposes a thick oil viscosity reducer, calculated according to mass percentage, including: free azacarbene 5wt%, tert-butyl hydroperoxide 30wt%, hydrogen donor methanol 5wt%, phosphoric acid 5wt%, emulsifier Span 60 0.5wt%, the rest is solvent benzene, 100% in total.

[0036] The preparation method of the heavy oil viscosity reducer in this example includes the following steps: according to the proportion, mix the free azacarbene with the solvent benzene at 20°C, then add the emulsifier Span 60 and the hydrogen donor methanol to continue mixing , then add tert-butyl hydroperoxide and phosphoric acid to continue mixing to obtain the thick oil viscosity reducer.

Embodiment 2

[0038] This example proposes a heavy oil viscosity reducer, calculated according to mass percentage, including: free azacarbene 7wt%, tert-butyl hydroperoxide 25wt%, hydrogen donor ethanol 2wt%, phosphoric acid 6wt%, emulsifier Span 80 0.7wt%, the rest is solvent benzene, 100% in total.

[0039] The preparation method of the heavy oil viscosity reducer in this example includes the following steps: according to the proportion, mix the free azacarbene with the solvent benzene at 30°C, then add the emulsifier Span 80 and the hydrogen donor ethanol to continue mixing , then add tert-butyl hydroperoxide and phosphoric acid to continue mixing to obtain the thick oil viscosity reducer.

Embodiment 3

[0041] This example proposes a thick oil viscosity reducer, calculated according to mass percentage, including: free azacarbene 8wt%, tert-butyl hydroperoxide 20wt%, hydrogen donor formic acid 3wt%, phosphoric acid 10wt%, emulsifier Span 60 1wt%, and the rest is solvent cyclohexane, totaling 100%.

[0042] The preparation method of the heavy oil viscosity reducer in this example includes the following steps: according to the proportion, mix the free azacarbene with the solvent cyclohexane at 30°C, and then add the emulsifier Span 60 and the hydrogen donor formic acid Continue mixing, then add tert-butyl hydroperoxide and phosphoric acid and continue mixing to obtain the thick oil viscosity reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com