High-capacity P2-type positive electrode material of sodium-ion battery, and method for orderly improving specific capacity by inhibiting sodium/vacancy

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of reduced diffusion rate, limited material capacity, etc., and achieves improved transmission, simple and easy preparation process, and excellent discharge ratio. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

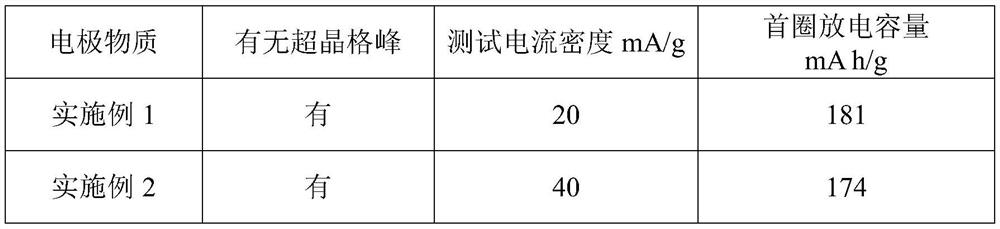

Embodiment 1

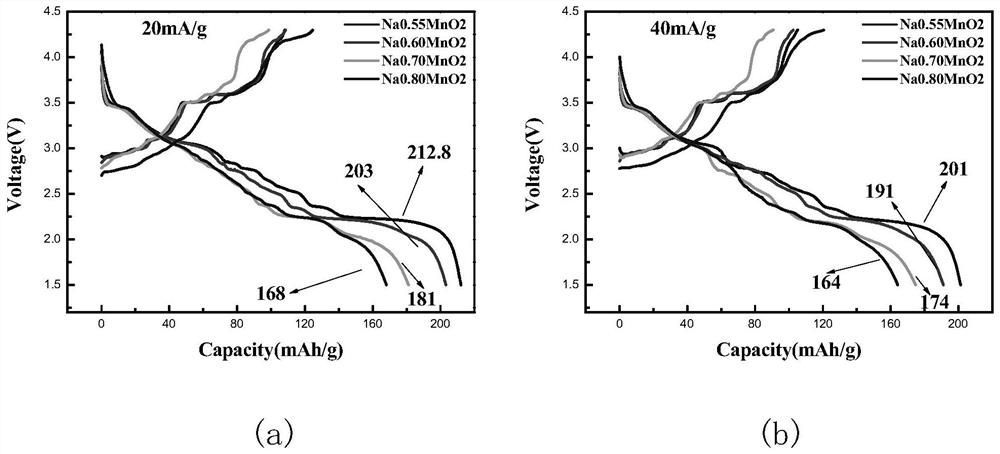

[0026] (1) Preparation of Na 0.70 MnO 2 Cathode material.

[0027] Weigh Na according to the corresponding proportion 2 CO 3 , Mn 2 o 3 Ball milled for 24 hours, pressed into a disc with a diameter of 10 mm under a pressure of 10 MPa, and calcined at 1000 °C for 12 hours in a muffle furnace to obtain a sample powder.

[0028] (2) For Na 0.70 MnO 2 Sample powder for XRD test

[0029] Using an X-ray diffractometer, the Na 0.70 MnO 2 The XRD pattern of the sample powder is used to analyze the material effectively with reference to the standard PDF card.

[0030] (3) Preparation of Na 0.70 MnO 2 Composite cathode

[0031] The prepared positive electrode material is uniformly mixed with the conductive additive Super-P and the binder polyvinylidene fluoride (PVDF) in a mass ratio of 8:1:1, and an appropriate amount of N-methylpyrrolidone is added, and after pulping and smearing , drying and other processes to obtain the composite positive electrode.

[0032] (4) Assem...

Embodiment 2

[0037](1) Preparation of Na 0.70 MnO 2 Cathode material.

[0038] Weigh Na according to the corresponding proportion 2 CO 3 , Mn 2 o 3 , ball milled for 24h, pressed into a disc with a diameter of 10mm under a pressure of 10MPa, and calcined at 1000°C for 12h in a muffle furnace to obtain a sample powder.

[0039] (2) For Na 0.70 MnO 2 The sample powder is subjected to XRD test and the data is processed and analyzed (the specific steps are the same as in Example 1).

[0040] (3) Preparation of Na 0.70 MnO 2 Composite positive electrode (the specific steps are the same as in Example 1).

[0041] (4) Assemble the sodium ion battery (the specific steps are the same as in Example 1).

[0042] (5) Sodium ion battery test

[0043] A charge-discharge test was performed on the above-mentioned sodium ion battery at a constant current density of 40mA / g within a voltage range of 1.5-4.3v using a charge-discharge instrument.

Embodiment 3

[0045] (1) Preparation of Na 0.60 MnO 2 Cathode material.

[0046] Weigh Na according to the corresponding proportion 2 CO 3 , Mn 2 o 3 , ball milled for 24h, pressed into a disc with a diameter of 10mm under a pressure of 10MPa, and calcined at 1000°C for 12h in a muffle furnace to obtain a sample powder.

[0047] (2) For Na 0.60 MnO 2 The sample powder is subjected to XRD test and the data is processed and analyzed (the specific steps are the same as in Example 1).

[0048] (3) Preparation of Na 0.60 MnO 2 Composite positive electrode (the specific steps are the same as in Example 1).

[0049] (4) Assemble the sodium ion battery (the specific steps are the same as in Example 1).

[0050] (5) Sodium ion battery test (the specific steps are the same as in Example 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com