Power module packaging structure and manufacturing method thereof

A technology of packaging structure and power module, which is used in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of heat not being dissipated in time, over-temperature failure of power modules, etc., achieving a simple manufacturing process and eliminating heat. resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

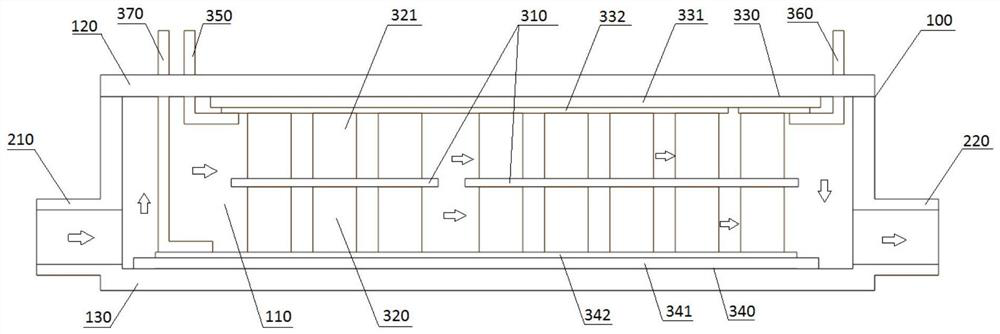

[0047] figure 1 It is a schematic structural diagram of the package structure of the power module in Embodiment 1 of the present application. Such as figure 1 As shown, in the assembled state, the upper electrode casing assembly of the package casing 100 of the power module packaging structure includes the upper casing 120 and the upper lining plate 330, and the lower electrode casing assembly includes the lower casing 130 and the lower lining plate 340, Wherein, the upper housing 120 is a plate structure, the lower housing 130 is a groove structure, the cooling liquid inlet 210 and the cooling liquid outlet 220 are both arranged on the lower housing 130, the upper housing 120 covers the opening of the lower housing 130 and Sealed tight connection is realized by screws.

[0048] Preferably, a sealing ring (not shown in the figure) is provided at the junction of the upper shell 120 and the lower shell 130 to further strengthen the sealing of the cavity 110 and prevent leakage...

Embodiment 2

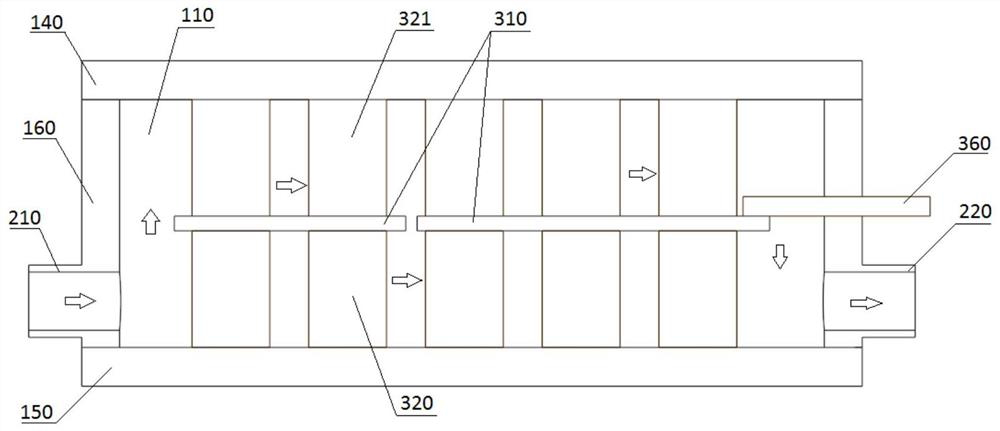

[0063] figure 2 It is a schematic diagram of a package structure of a power module provided in another embodiment of the present application. Such as figure 2As shown, the upper electrode casing assembly of the power module packaging structure includes an upper metal electrode 140, and the lower electrode casing assembly includes a lower metal electrode 150 and an intermediate casing 160, wherein the upper metal electrode 140 and the lower metal electrode 150 are both plate structure and can be directly connected to an external circuit, the coolant inlet 210 and the coolant outlet 220 are both arranged on the middle housing 160 , and the three are combined in a sealed manner to form the cavity 110 of the present application.

[0064] In this embodiment, the components of the power chip may also include a power chip 310 and upper surface metal pillars 321 and lower surface metal pillars 320 fixedly arranged on the upper surface of the power chip 310 .

[0065] When manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com