A kind of closed circulation method sponge titanium production equipment with simple operation

A closed-loop, production equipment technology, applied in the field of titanium sponge production, can solve the problems of low reaction rate, high energy consumption per unit of production, oxidation of titanium sponge, etc., to avoid oxidation of titanium sponge, rapid reaction rate, and reduce energy consumption per unit of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

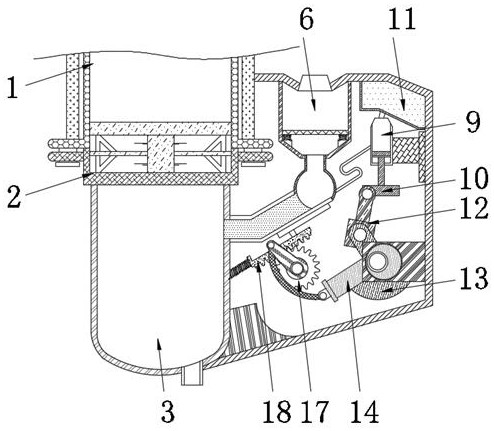

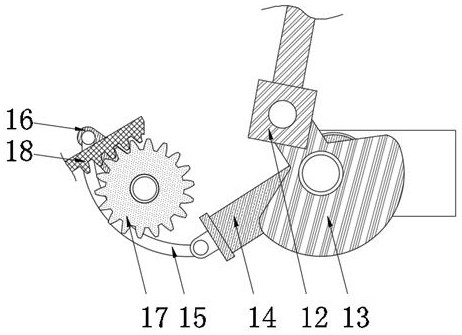

[0021] The present invention provides a kind of closed circulation method sponge titanium production equipment with simple operation, as attached figure 1 To attach Figure 5 Shown: includes the distillation condensation reactor 1, the bottom of the distillation condensation reactor 1 is fixed with a large reactor cover 2, the lower surface of the reactor cover 2 is movable with a reduction reactor 3, and the left and right sides of the reduction reactor 3 The surface is fixedly connected with a feeding pipeline 4, and the feeding pipeline 4 is arranged symmetrically on the left and right sides with the inner center of the reduction reactor 3 as the criterion. The bottom of the storage hopper 6 and the bottom of the mixing bin 5 are spherical structures. A one-way valve is provided at the connection between the mixing bin 5 and the storage hopper 6. A mesh plate 7 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com