Spiral three-stage quicklime slaking device and method

A quicklime and spiral technology, applied in the field of spiral three-stage quicklime digestion device, can solve the problems of uneven water spraying, poor adjustability, high viscosity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

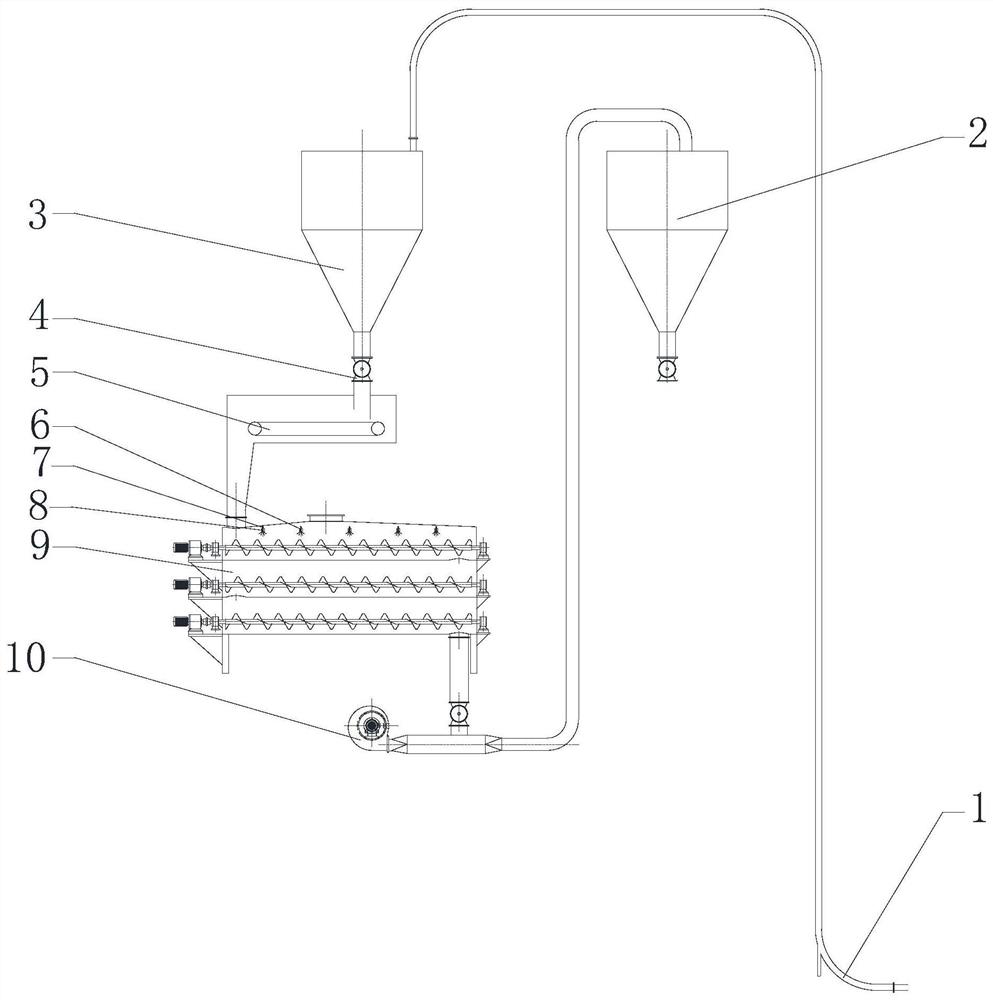

[0039] A spiral type three-stage quicklime digestion device, the spiral three-stage quicklime digestion device includes lime lime pipes, quicklime bins, ash discharge valves, feeders, screw digesters, pressure fans and lime bins connected in sequence, the An atomizing nozzle is installed on the top of the spiral digester, and the atomizing nozzle is supplied with air by a pressure air pipe, and water is supplied by a pressure water pipe, and a spiral stirring rod is arranged inside the spiral digester, and the spiral stirring rod is driven by a motor;

[0040] The feed inlet of the quicklime bin is connected to the lime pipe, the outlet of the quicklime bin is connected to the feeder inlet, the outlet of the quicklime bin is provided with a discharge valve, and the feeder Conveyor belt is provided inside, the discharge port of the feeder is connected with the feed port of the spiral digester, the discharge port of the spiral digester is provided with a pressing fan, and the dis...

Embodiment 2

[0060] A three-stage quicklime digestion method, the three-stage quicklime digestion method adopts the spiral three-stage quicklime digestion device described in any one of the above.

[0061] Further speaking, it can also be considered in the present invention that the three-stage quicklime digestion method includes the following steps:

[0062] The temperature range in the first-stage spiral digester is 140-160°C. If the temperature does not meet the range requirements, it means that the digestion is not complete. It is necessary to increase the amount of water and reduce the speed according to the feeding amount; if the temperature exceeds the range, then Increase the rotation speed to ensure that the temperature range in the second-stage spiral digester reaches 150-180°C. If the digestion effect still cannot be achieved, control the third-stage spiral digester to reduce or increase the speed to ensure that the temperature range is 70-90°C. This proves that the digestion re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com