An aluminum alloy round tube polishing equipment

An aluminum alloy and round tube technology, which is applied in the field of aluminum alloy round tube polishing equipment, can solve the problems of high force on the polished item, dent or damage of the tube body, damage to the polished item, etc., achieve high speed, reduce the scrap rate, The effect of increasing productivity

Active Publication Date: 2022-05-31

鄂州天信工贸有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most of the polishing machines on the market use the polishing wheel to approach and touch the object to be polished to complete the polishing. In this hard contact, the object to be polished is subjected to a large force. When the polishing wheel process is improper or the polishing machine fails, it is easy to cause being polished Damage to polished items, especially for soft tubes such as aluminum alloy tubes, the tube body is more frequently dented or damaged during the polishing process, resulting in a higher scrap rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0040] In another embodiment, the hanging hole is inlaid with a hard metal ring for enhancing its stress strength. such an embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

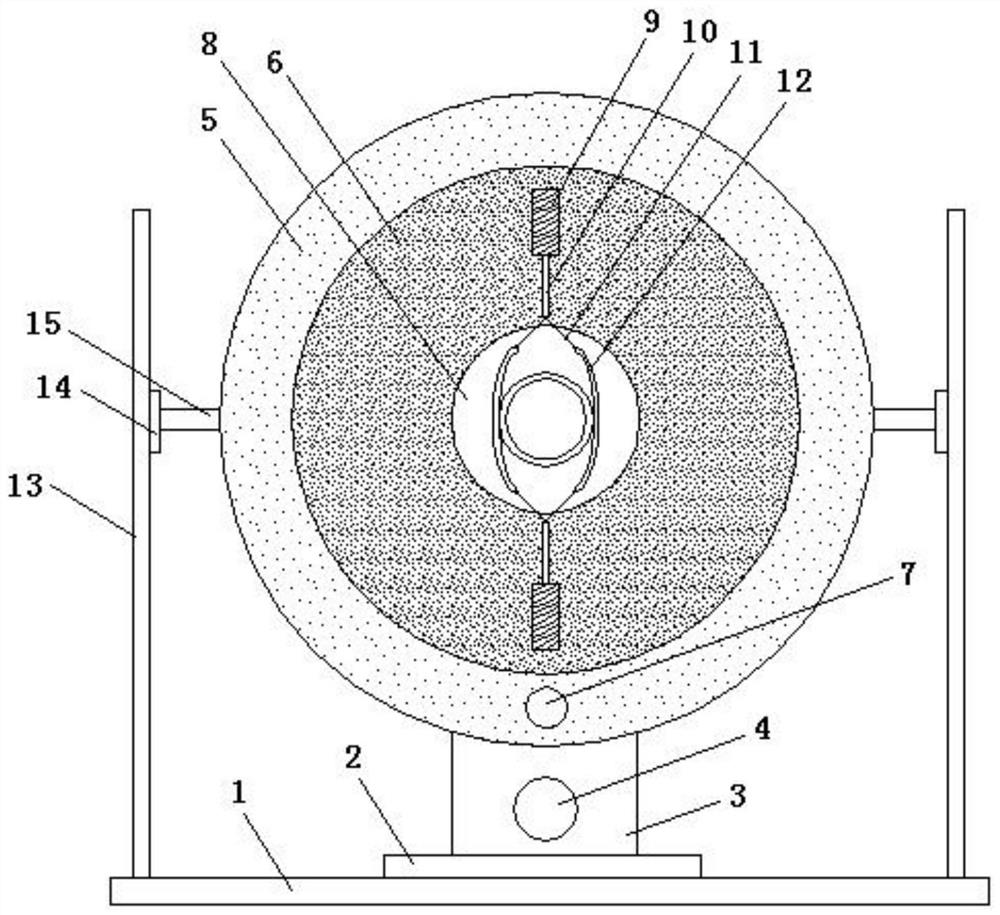

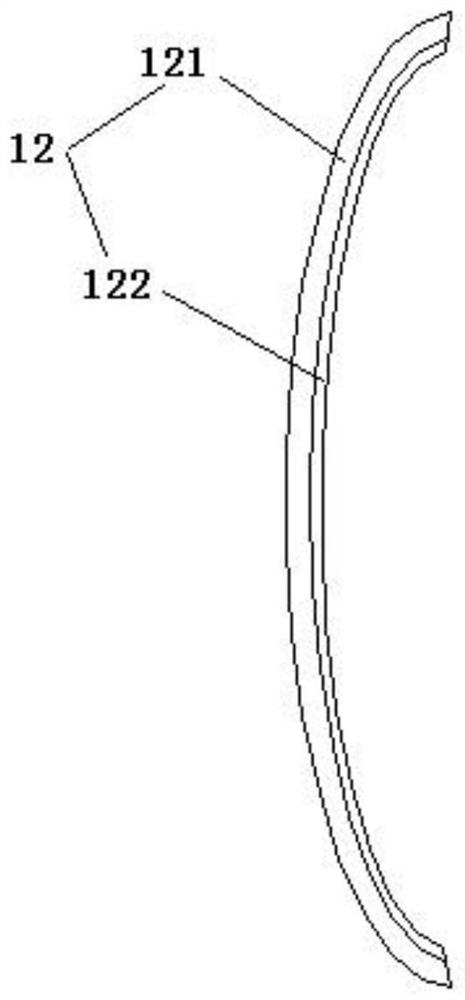

The invention discloses a polishing equipment for an aluminum alloy round tube, which comprises a base. The base is provided with a transverse movement mechanism for driving a mounting plate to move axially along the aluminum alloy round tube. The circular rotating mechanism of the round pipe is equipped with a first cylinder, a cable and a polishing clip on the circular rotating plate to polish the aluminum alloy round pipe, and the polishing clip is pulled by the first cylinder to be soft It is pressed on the surface of the aluminum alloy round tube, and then the circular polishing is carried out under the drive of the rotating mechanism, and at the same time, the axial polishing is carried out by the traversing mechanism, so as to quickly complete the whole tube polishing of the aluminum alloy tube. When this equipment is used for the polishing of aluminum alloy round tubes, it can not only effectively prevent the aluminum alloy tubes from being damaged during the polishing process, reduce the reject rate in the polishing process, but also continuously and uninterruptedly polish the entire aluminum alloy long round tubes at a high speed. , high efficiency, can greatly increase production capacity.

Description

A kind of aluminum alloy round tube polishing equipment technical field The present invention relates to the field of polishing equipment, in particular to a kind of aluminum alloy round pipe polishing equipment. Background technique At present, the working mode of the polishing machine on the market is mostly by the polishing wheel approaching and contacting the object to be polished to complete the polishing. Light, the object to be polished in this hard contact is subjected to a large force, which is easy to cause when the polishing wheel process is improper or the polishing machine fails. Damage to objects to be polished, especially for soft pipes such as aluminum alloy pipes, the pipe body is dented or broken during the polishing process. Damage is more frequent, resulting in a higher scrap rate. SUMMARY OF THE INVENTION The object of the present invention is to provide a kind of aluminum alloy round pipe polishing equipment, to solve the above-mentioned backg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B29/08B24B41/06B24B47/12B24B41/02B24B47/00

CPCB24B29/08B24B41/06B24B47/12B24B41/02B24B47/00Y02P70/10

Inventor 肖汉平

Owner 鄂州天信工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com