Carbon brush cambered surface automatic grinding tool and using method thereof

A technology for grinding tools and carbon brush arc surfaces, which is applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems of difficult control of grinding accuracy, time-consuming and labor-consuming, low efficiency, etc. Improving the working environment and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

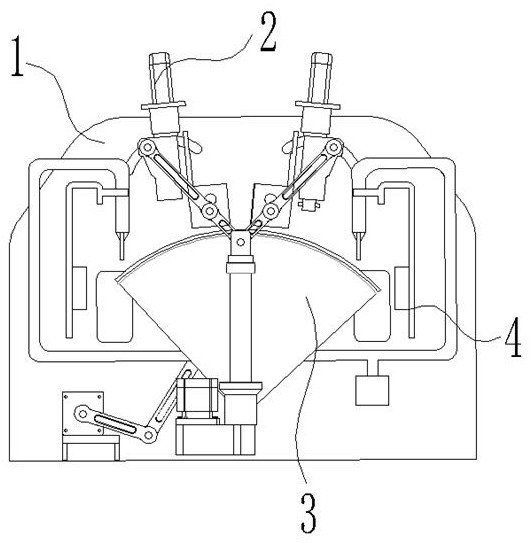

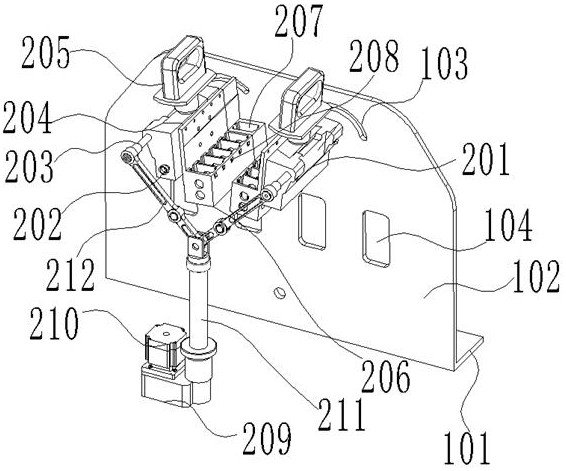

[0043] A carbon brush arc surface automatic grinding tool is characterized in that it includes a bracket 1, a positioning and clamping mechanism 2 and a grinding mechanism 3;

[0044]Wherein said support 1 comprises a support platform 101, and a support plate 102 is vertically arranged on the support platform 101, two support plates 1 are arranged symmetrically, and the grinding mechanism 3 is arranged between the two supports 1; the grinding mechanism 3 includes There are two fan-shaped support plates 301, and the arc surface on the top of the two fan-shaped support plates 301 is connected with a grinding wheel plate 302. The fan-shaped support plates 301 are arranged on both sides of the grinding wheel plate 302. Rotationally connected between the two support plates 102, a connecting rod 304 is arranged above the rotating shaft 303, and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com