A valve pouring molding cooling process

A casting molding and process technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of low valve casting molding processing efficiency, and achieve the effect of maintaining uniform heat dissipation, improving processing efficiency, and rapid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is further illustrated in conjunction with the accompanying drawings and specific embodiments.

[0022] Embodiments of the present invention are:

[0023] A valve cast formation cooling process, including the following steps:

[0024] 1) After drying the mold, it is divided into two parts, respectively, the first sand and second sand;

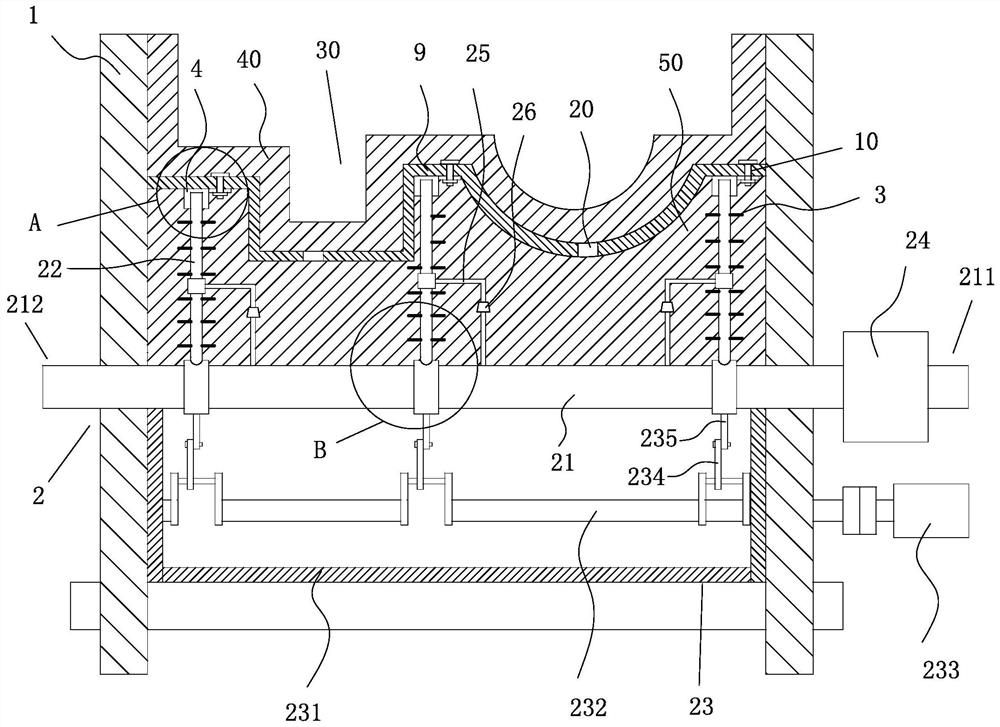

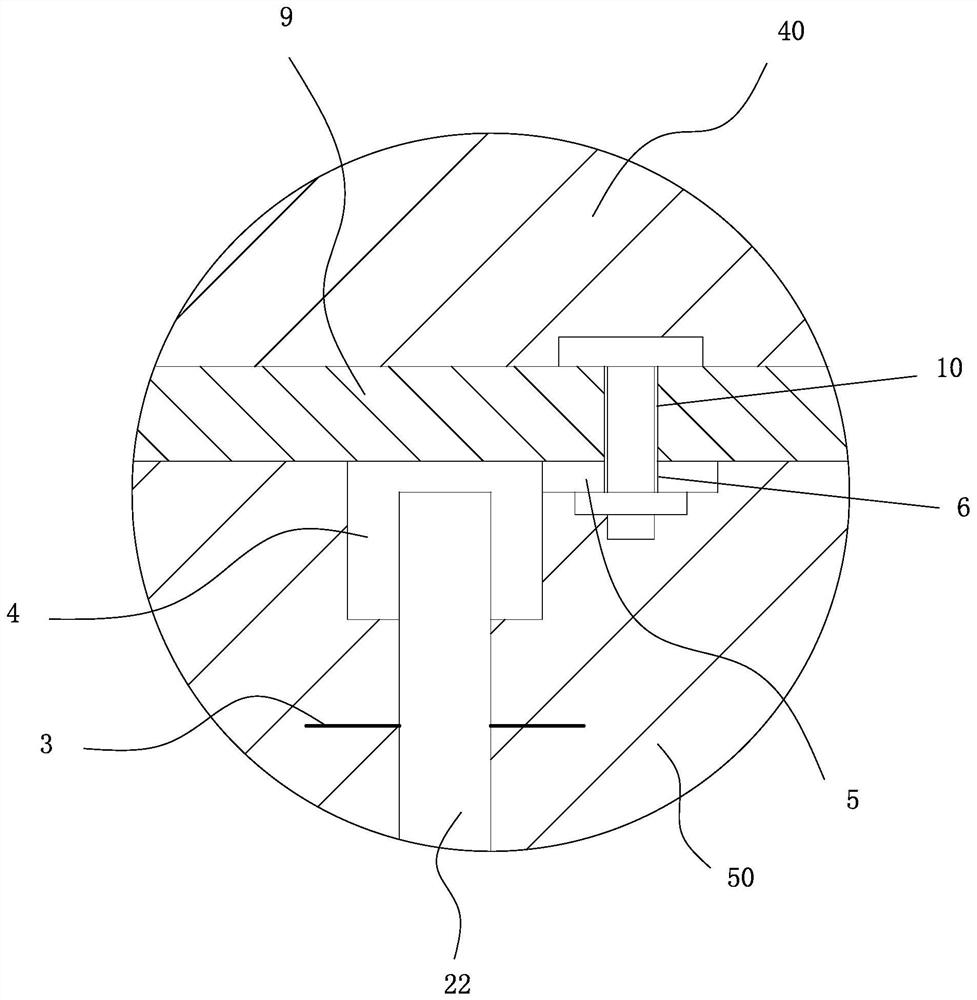

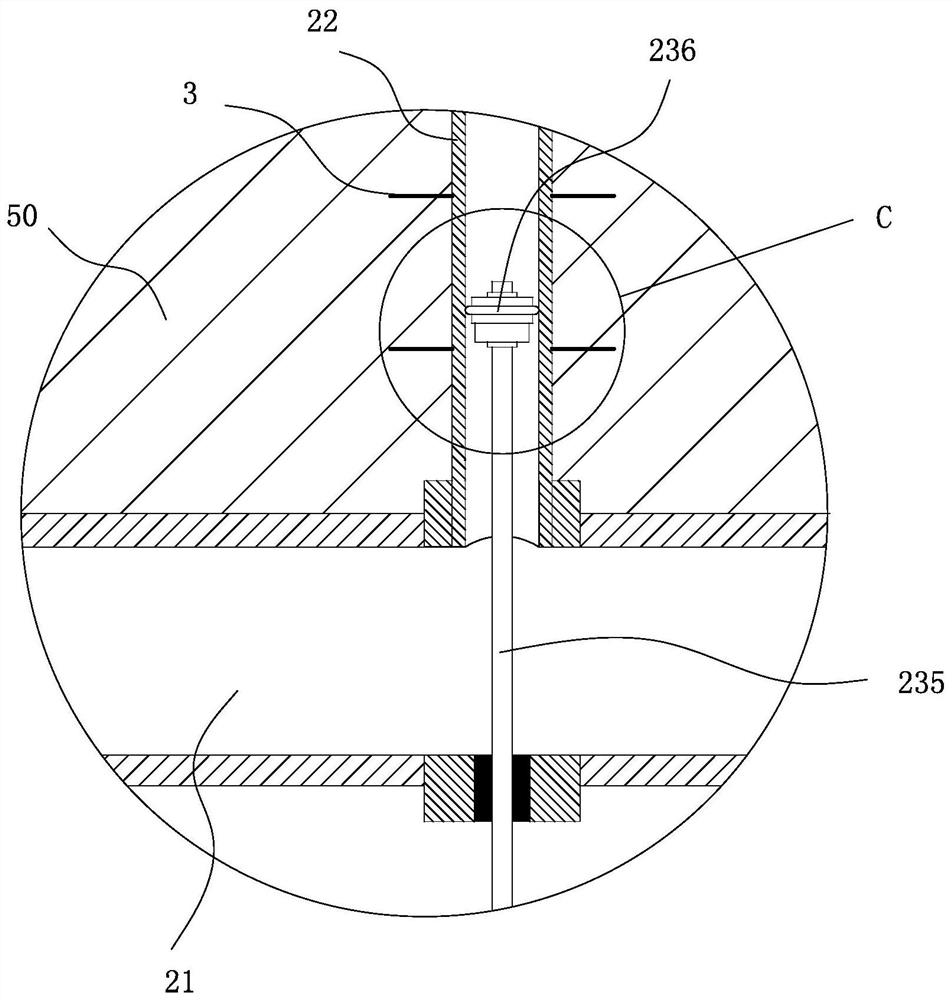

[0025] 2) Fill the first sand in the sand mold 1, and the cooling device 2 is buried in the sand mold 1, reference figure 1 , figure 2 , image 3 and Figure 4 As shown, the cooling device 2 includes a pumping device 23 having a water slide 21 disposed along a horizontal distribution, a pumping device 23 that is provided in a vertical direction distribution, and a pumping device 23 for cooling water in the accelerated heat dissipating tube 22, and the heat tube 22 The outer surface is provided with a heat-dissipating fin 3, thereby accelerating the heat exchange efficiency of the heat radiating tube 22, and the heat pipe 22 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com