Method for preparing ternary copper-based catalyst through electrolysis

A catalyst and ternary copper technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of ternary copper-based catalysts with limited performance, complicated preparation process, and small specific surface area. Achieve the effects of easy monitoring, high preparation efficiency and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0030] A method for preparing a ternary copper-based catalyst by electrolysis, the method is as follows: a metal copper electrode and a counter electrode are co-placed in an electrolytic solution for pulse electrolysis, and a saturated calomel electrode is set as a reference electrode, and a pulse current is applied to make the metal Copper oxide and cuprous oxide are produced intermittently on the surface of the copper electrode, and the ternary copper-based catalyst is peeled off from the metal copper electrode;

[0031] When a forward voltage is applied, the metal copper electrode acts as an anode and loses electrons, and when a reverse voltage is applied, the counter electrode acts as an anode and loses electrons.

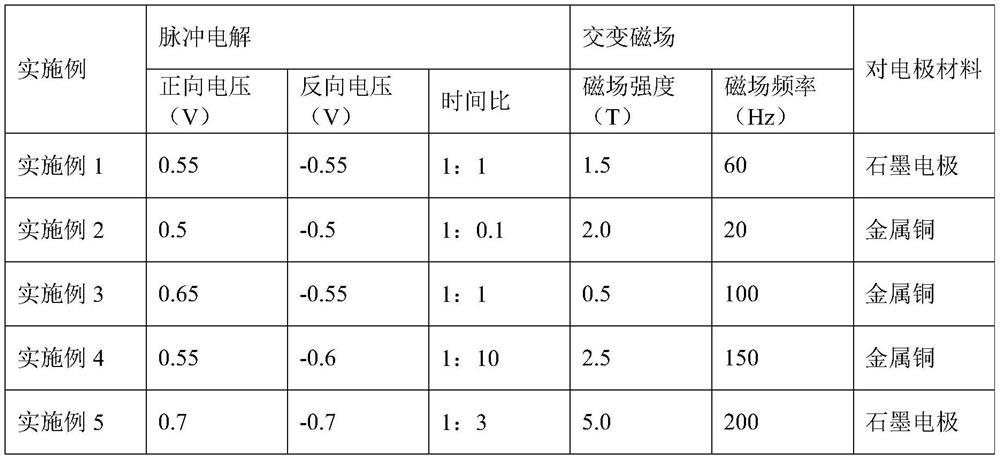

[0032] The specific preparation parameters of Examples 1-5 are shown in Table 1 below.

[0033] Table 1 specific preparation parameters

[0034]

[0035] Here, the time ratio is the application time ratio of the forward voltage and the reverse voltage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com